Selective hydrogenation method

A selective, hydrogen-oil technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, etc., can solve problems such as decline and catalyst activity decline, and achieve mature technology, Effects of extended life and simple reactor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

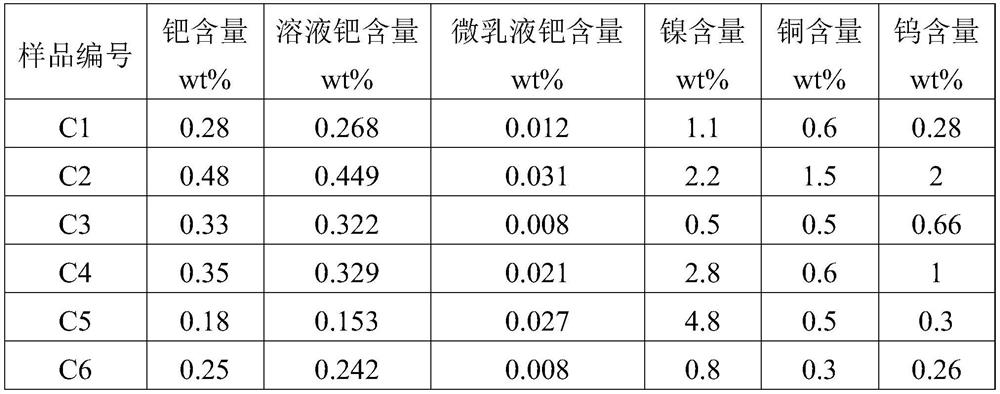

[0062] Embodiment uses the preparation of catalyst 1~6

[0063] Preparation of Catalyst C1:

[0064] Catalyst carrier preparation: commercially available bimodal pore distribution spherical alumina carrier with a diameter of 3-4mm was used. After calcination at 950°C for 4 hours, the pore size distribution ranges were 10-25nm and 50-270nm respectively, the water absorption rate was 72%, and the specific surface area 146m 2 / g, weigh the carrier 150g.

[0065] Catalyst preparation:

[0066] (1) Palladium chloride is prepared as an active component impregnation solution, and the pH is adjusted to 2.0, then the carrier is added to the Pd salt solution, after impregnation and adsorption for 3 hours, dried at 100°C for 4h, and roasted at 550°C for 2h to obtain a semi-finished catalyst C1-A.

[0067] (2) The ammonium metatungstate is completely dissolved into the impregnating solution, impregnated with equal volume, impregnated the semi-finished catalyst C1-A in the prepared sol...

Embodiment 1

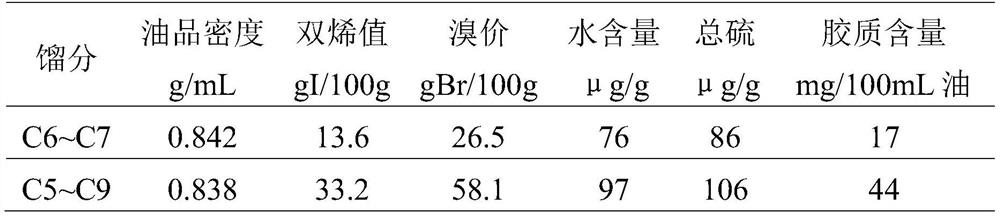

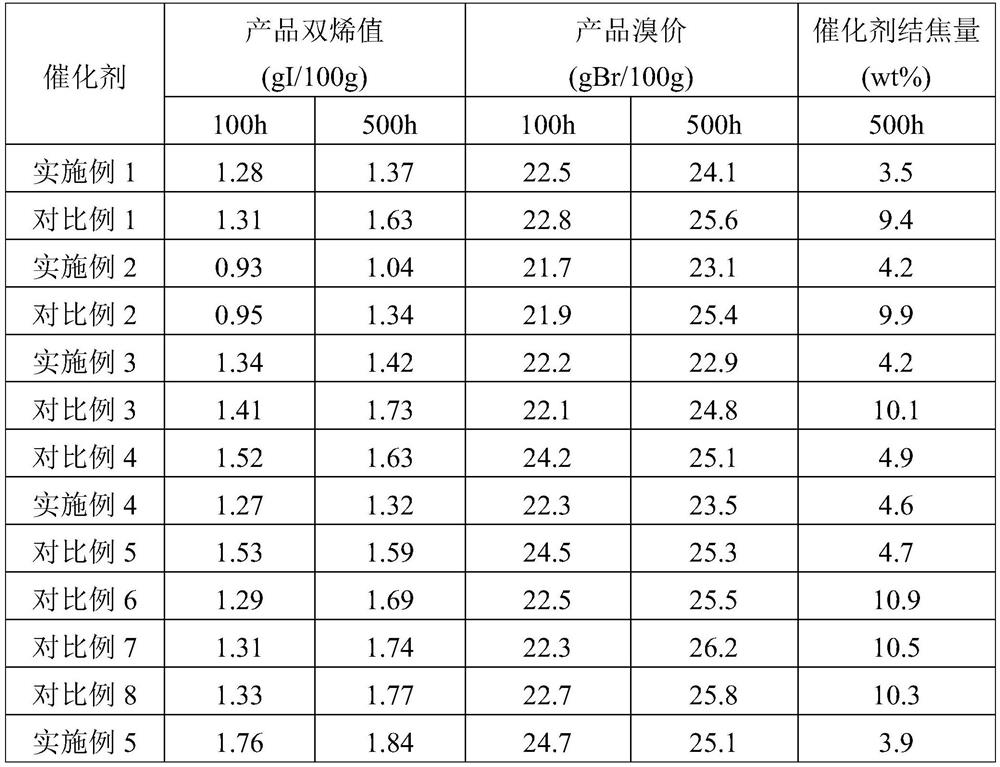

[0126] Using C6-C7 distillate as raw material, at an inlet temperature of 50°C, a reaction pressure of 3.0MPa, and a liquid hourly space velocity of 2.0h -1 1. Run for 500 hours under the condition of hydrogen oil volume ratio of 200:1, and sample and analyze the diene value and bromine value in the product every 24 hours. The average value of the analysis results is shown in Table 3.

Embodiment 2

[0131] Using C6-C7 distillate as raw material, at an inlet temperature of 40°C, a reaction pressure of 3.5MPa, and a liquid hourly space velocity of 2.0h -1 1. Run for 500 hours under the condition of hydrogen-oil volume ratio of 300:1, and sample and analyze the diene value and bromine value in the product every 24 hours. The average value of the analysis results is shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com