Hydrorefining method of middle and low distillate oil

A technology for hydrorefining and distillate oil, which is applied in the petroleum industry, processing hydrocarbon oil, refining to remove heteroatoms, etc. The effect of good chemical stability and thermal stability, strong anti-coking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

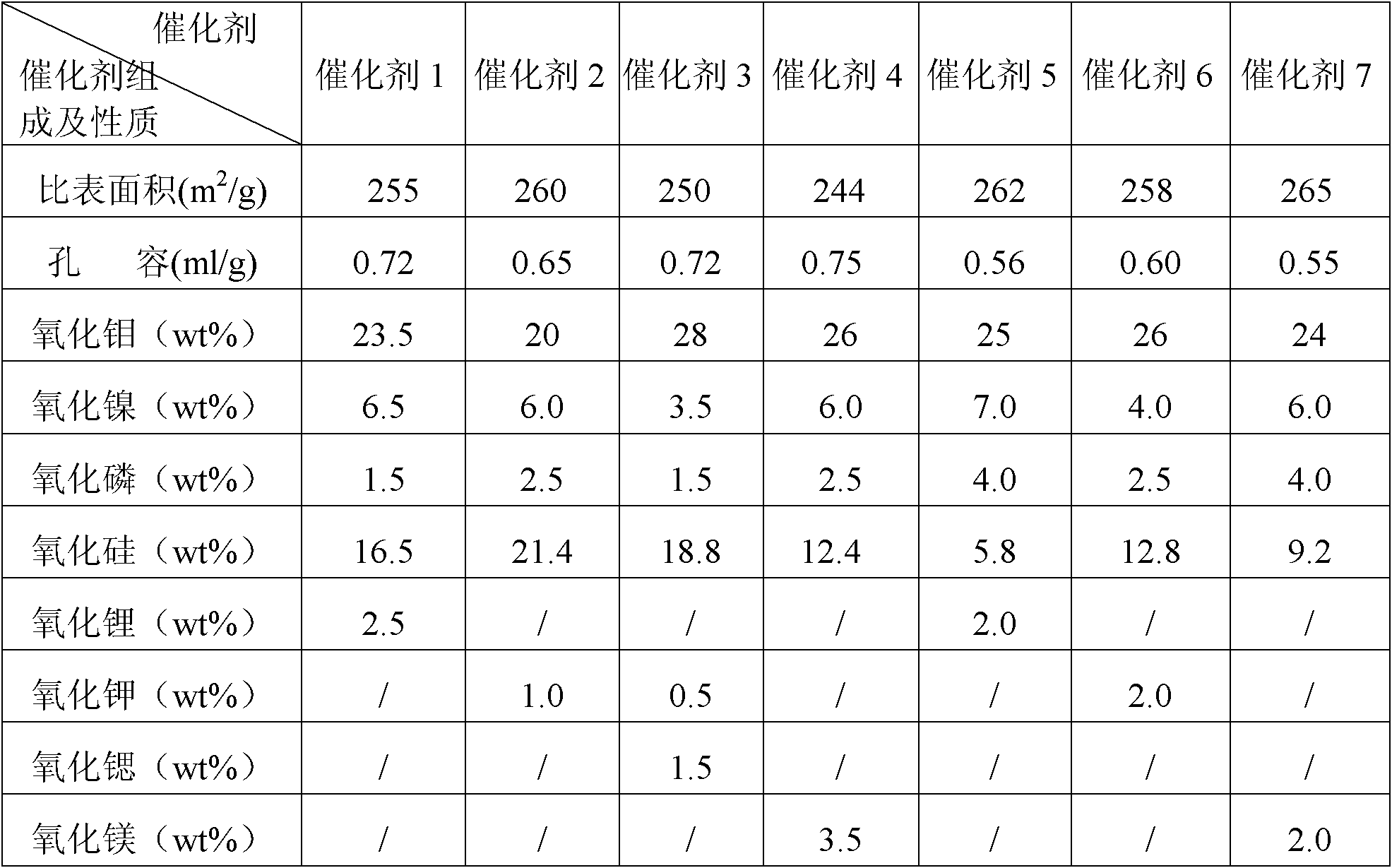

[0049] Embodiment uses the preparation of catalyst 1~7:

[0050] Preparation of Catalyst 1:

[0051] Configure 2L concentration of 120gAl 2 o 3 / L of sodium metaaluminate solution is placed in the glue tank, the temperature of the glue tank is controlled at 45°C, and 65v% CO is introduced under stirring conditions. 2 Mixed gas of +35v% air, the flow rate of carbon dioxide in the mixed gas is 3Nm 3 / h. When the pH value reaches 10.0, stop feeding the mixed gas, and then age for 20 minutes to obtain pseudo-boehmite slurry.

[0052] Configure 2L concentration of 120gAl 2 o 3 / L sodium metaaluminate solution is placed in the gel tank, and then add 2L 80gSiO 2 / L of sodium silicate solution, control the temperature of the glue tank at 30°C, and feed 60v% CO 2 Mixed gas of +40v% air, CO in the mixed gas 2 The flow rate is 3Nm 3 / h, the pH at the end point was controlled to be 10.0, and the amorphous silicon-aluminum slurry was obtained by aging for 15 minutes.

[0053] Un...

Embodiment 1

[0088] Put the fresh catalyst 1 into a 100ml adiabatic bed reaction device, and first carry out the sulfuration of the catalyst: add carbon disulfide to cyclohexane to make sulfurized oil with a sulfur content of about 1000μg / g, and the reactor is heated to 240°C to start adding sulfurized oil. Pressure 2.5Mpa, vulcanized oil volume space velocity 3.0h -1 , the hydrogen / sulfurized oil volume ratio is 300:1, and then the temperature is raised to 350°C at a heating rate of 10°C / h and maintained for 25h to complete the sulfurization treatment of the catalyst.

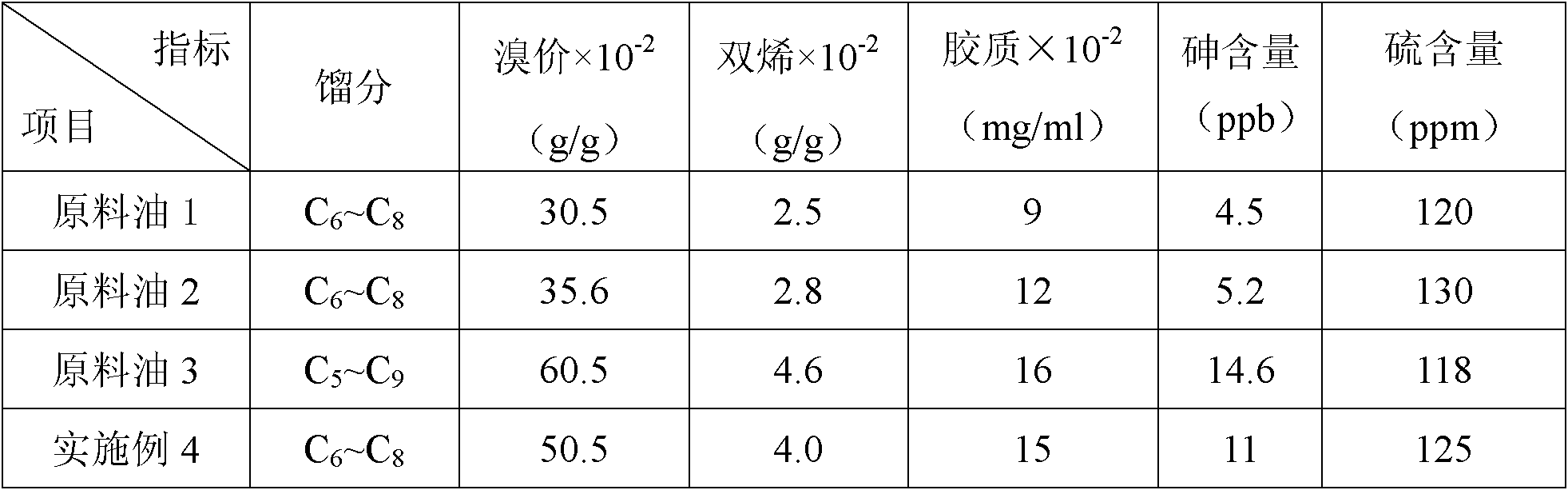

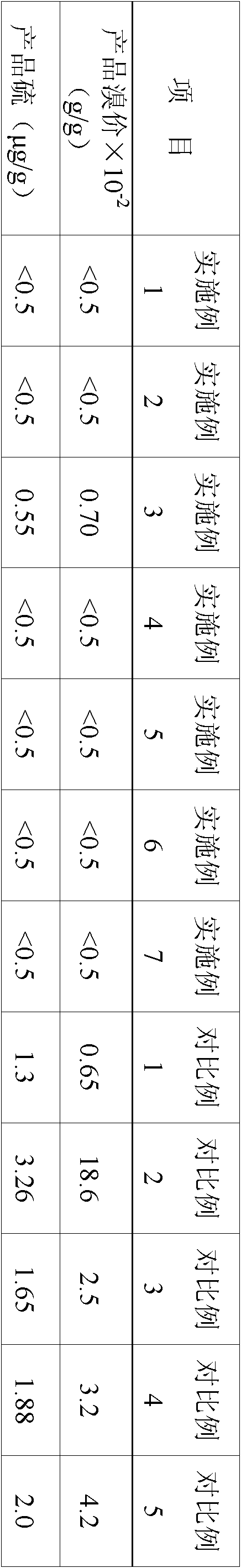

[0089] After the vulcanization treatment is completed, use the raw material oil 1 as the raw material, at the inlet temperature of 220°C, the reaction pressure of 2.4MPa, and the liquid volume space velocity: 4h -1 , and run for 200h under the condition of hydrogen to oil volume ratio of 300. The bromine value and sulfur content in the product were sampled and analyzed every 24h, and the results are shown in Table 3.

Embodiment 2

[0091] The fresh catalyst 2 was loaded into a 100ml adiabatic bed reactor, and the catalyst sulfidation treatment method was the same as in Example 1.

[0092] After the vulcanization treatment, use the raw material oil 2 as the raw material, at the inlet temperature of 240°C, the reaction pressure of 2.6MPa, the liquid volume space velocity: 4.5h -1 , the hydrogen to oil volume ratio of 350 operating conditions of 200h. The bromine value and sulfur content in the product were sampled and analyzed every 24h, and the results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com