Highlight AS/PA9T composite material with an electromagnetic shielding function and preparation method thereof

A composite material and electromagnetic shielding technology, which is applied in the field of AS/PA9T composite material with high gloss and electromagnetic shielding function and its preparation, to achieve the effect of enhanced tensile resistance and enhanced chemical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

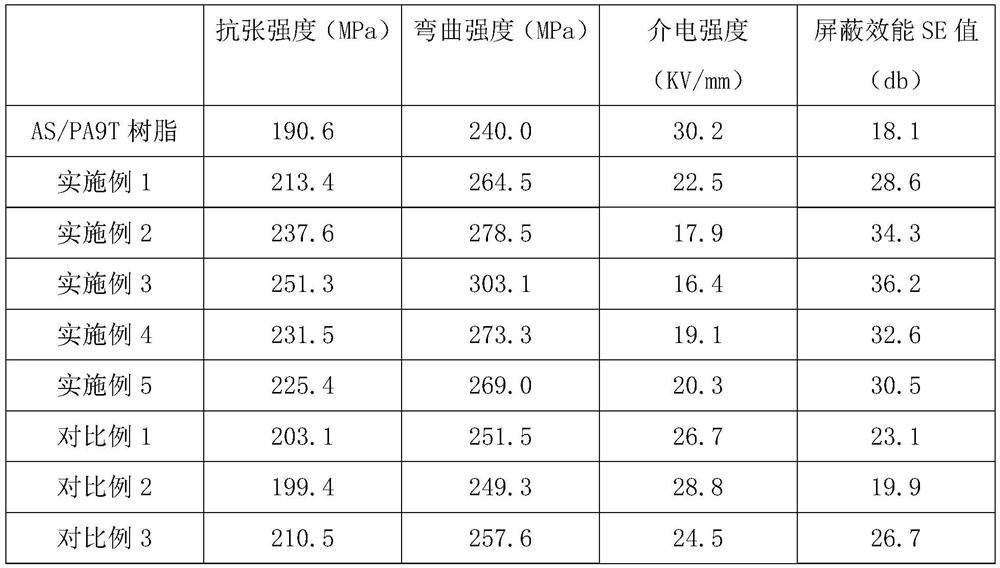

Examples

Embodiment 1

[0019] A high-gloss AS / PA9T composite material with electromagnetic shielding function, consisting of the following raw materials and their parts by weight: 0.5 parts of graphene, 0.5 parts of carbon nanofibers, 3 parts of dispersant, 49.92 parts of terephthalic acid, azelaic 46.08 parts of amine and 30 parts of AS pure resin, its preparation method comprises the following steps:

[0020] (1) The number of layers of 0.5 parts by weight is 1 layer, and the specific surface area is 100m 2 After the graphene powder of / g is mixed with 0.5 parts by weight of carbon nanofibers with a diameter of 10nm, 1 part by weight of dispersant N-methylpyrrolidone, EBS and zinc stearate are added for grinding to obtain a composite of carbon nanomaterials body;

[0021] (2) Under the protection of nitrogen, after ultrasonically dispersing the nano-carbon material complex in 100 parts by weight of N-methylpyrrolidone, add 49.92 parts by weight of terephthalic acid and 46.08 parts by weight of no...

Embodiment 2

[0024] An AS / PA9T composite material with high gloss and electromagnetic shielding function, consisting of the following raw materials and their parts by weight: 1 part of graphene, 1 part of carbon nanofiber, 3 parts of dispersant, 49.40 parts of terephthalic acid, azelaic 45.6 parts of amine and 30 parts of AS pure resin, its preparation method comprises the following steps:

[0025] (1) The number of layers of 1 part by weight is 10 layers, and the specific surface area is 2000m 2 After the graphene powder of / g is mixed with the carbon nanofiber of 500nm in 1 weight part diameter, add each 1 weight part of dispersing agent DMF, EBS and zinc stearate and grind and process, get nano-carbon material compound body;

[0026] (2) Under the protection of nitrogen, after ultrasonically dispersing the nano-carbon material complex in 100 parts by weight of N-methylpyrrolidone, add 49.40 parts by weight of terephthalic acid and 45.60 parts by weight of nonanediamine, room temperature...

Embodiment 3

[0029] An AS / PA9T composite material with high gloss and electromagnetic shielding function, consisting of the following raw materials and their parts by weight: 1.5 parts of graphene, 1.5 parts of carbon nanofiber, 3 parts of dispersant, 48.88 parts of terephthalic acid, azelaic 45.12 parts of amine and 30 parts of AS pure resin, its preparation method comprises the following steps:

[0030] (1) The number of layers of 1.5 parts by weight is 5 layers, and the specific surface area is 1000m 2 After the graphene powder of / g is mixed with 1.5 parts by weight of carbon nanofibers with a diameter of 200nm, each 1 part by weight of dispersant DMA, EBS and zinc stearate is added and ground to obtain a carbon nanomaterial compound;

[0031] (2) Under the protection of nitrogen, after ultrasonically dispersing the nano-carbon material complex in 100 parts by weight of N-methylpyrrolidone, add 48.88 parts by weight of terephthalic acid and 45.12 parts by weight of nonanediamine, room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com