Organic corrosion-inhibiting cooling liquid and preparation method thereof

A technology for coolant and corrosion inhibition, applied in the field of organic type corrosion inhibitor coolant and its preparation, can solve the problems of easy blockage of engine pipelines, engine overheating failure, corrosion inhibition performance decline, etc., so as to achieve less environmental pollution and increase service life , Enhance the effect of corrosion inhibition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

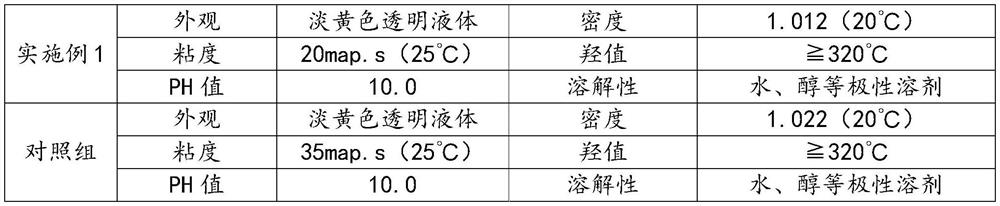

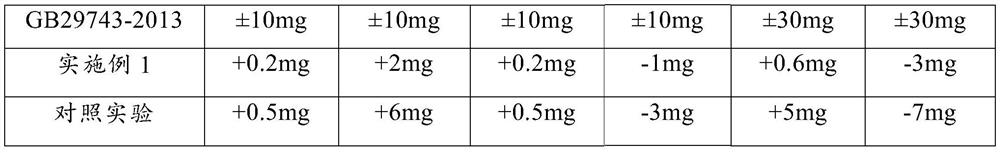

[0024] Example 1 provides an organic type corrosion-inhibiting cooling liquid, including the following components in weight percentage: 0.15% of tolyl benzotriazole or benzotriazole; compound component A: 0.8% of octanoic acid, 2-Ethylhexanoic acid 2.45%; compound component B: azelaic acid 1.35%, terephthalic acid 1.8%, neodecanoic acid 2.5%, sebacic acid 0.8%; sodium benzoate 1.2%; polyhexamethylene Base guanidine 0.7%; Fluorescein sodium 5ppm; Silicone defoamer 25ppm; The balance is water and ethylene glycol. The technical index of the organic type corrosion-inhibiting cooling liquid that embodiment 1 makes sees the following table 1:

[0025] The control experiment provides a kind of inorganic cooling liquid, including the following components in mass percentage: 0.15% benzotriazole, 0.35% triethanolamine, 0.21% sebacic acid, 0.15% sodium hydroxide, 0.14% sodium nitrate, Sodium nitrite 0.3%, sodium silicate 1.0%, water and ethylene glycol are added according to the freezin...

Embodiment 8

[0048] The difference between Example 8 and Example 1 is that the neodecanoic acid in the compound component B is replaced by 1,2,3-3 methylpentanoic acid; the difference between Example 9 and Example 1 is that the compound The amount of neodecanoic acid in component B is reduced, and another 1,2,3-3 methylpentanoic acid is added; the difference between Example 10 and Example 1 is that the compound component B lacks neodecanoic acid The difference between Example 11 and Example 1 is that azelaic acid will be lacking in the compounding component B; the mass percentage of the compounding component B in the total amount remains unchanged. From the experimental results of Examples 8-11 in Table 5, it can be known that some of the tested data of the cooling liquids in Examples 8-11 seriously exceed the requirements of the national standard. The anti-corrosion performance decreased significantly. This is because the combination of azelaic acid, terephthalic acid, neodecanoic acid an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com