Cleaning solution suitable for polyester fabrics

A technology of washing liquid and polymer, which is applied in the direction of detergent composition, detergent compounding agent, organic washing composition, etc., can solve the problems of no help in cleaning effect and inconvenient use, etc., so as to improve the effect of rewashing and reduce the Adsorption force, effect of short carbon chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A first aspect of the present invention provides:

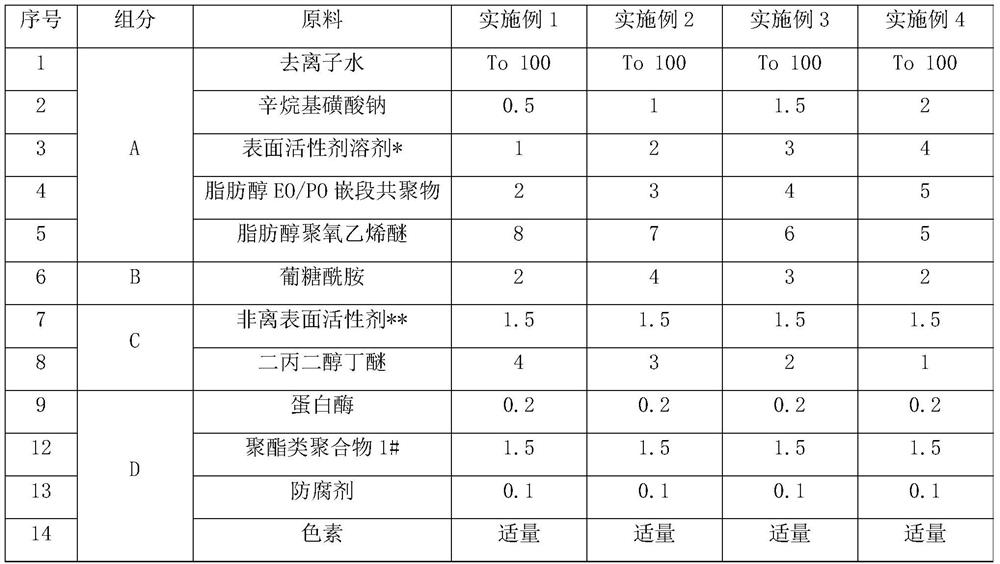

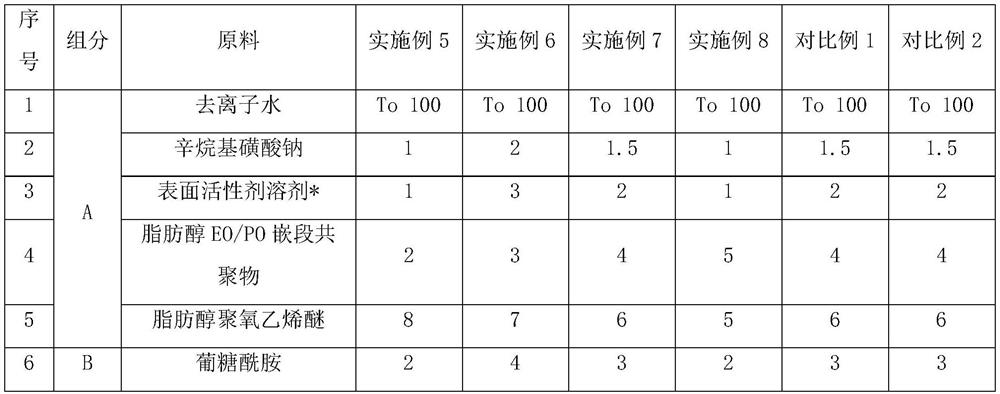

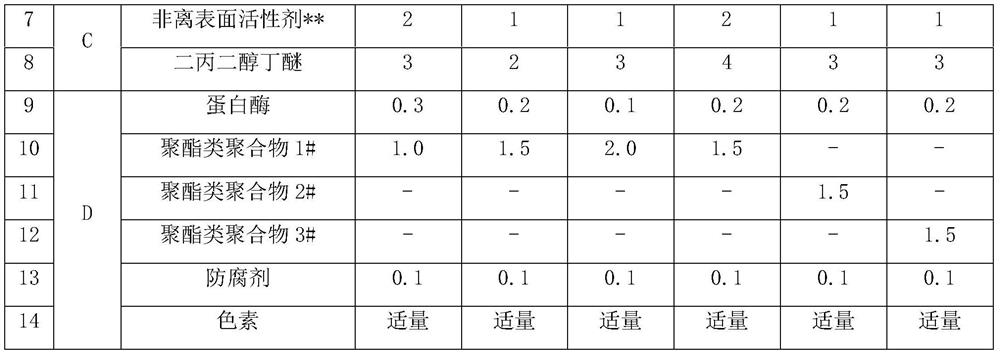

[0035] A kind of washing solution, in parts by mass, the composition of its washing active ingredient is:

[0036] 0.5-2.5 parts of sulfonate, 1-4 parts of surfactant solvent, 2-5 parts of fatty alcohol EO / PO block copolymer, 5-8 parts of fatty alcohol polyoxyethylene ether, 1-4 parts of glucamide, 0.5-2 parts of non-ionic surfactant, 1-4 parts of alcohol ether solvent, 0.1-0.3 parts of protease, 1-2 parts of polyester polymer.

[0037] In some instances, the detergent active consists of:

[0038] 1-1.5 parts of sulfonate, 1-3 parts of surfactant solvent, 4-5 parts of fatty alcohol EO / PO block copolymer, 6-7 parts of fatty alcohol polyoxyethylene ether, 2-3 parts of glucamide, 1-2 parts of nonionic surfactant, 2-3 parts of alcohol ether solvent, 0.2 part of protease, 1.5 parts of polyester polymer.

[0039] In some instances, the detergent active consists of:

[0040] 1.5 parts of sulfonate, 2 parts of surfactant s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com