Metallographic corrosive agent for nickel-based alloy, and using method

A nickel-based alloy and etchant technology, applied in the field of metallographic etchants, can solve problems such as failure of metallographic testing, uneven surface corrosion of samples, environmental pollution, etc. , good corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

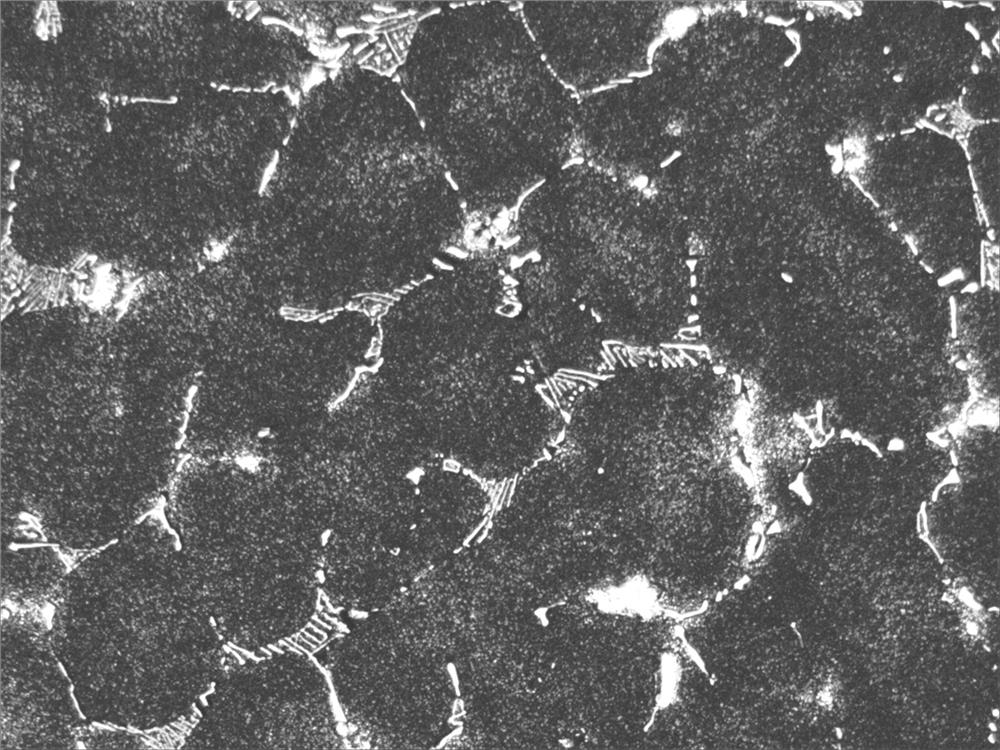

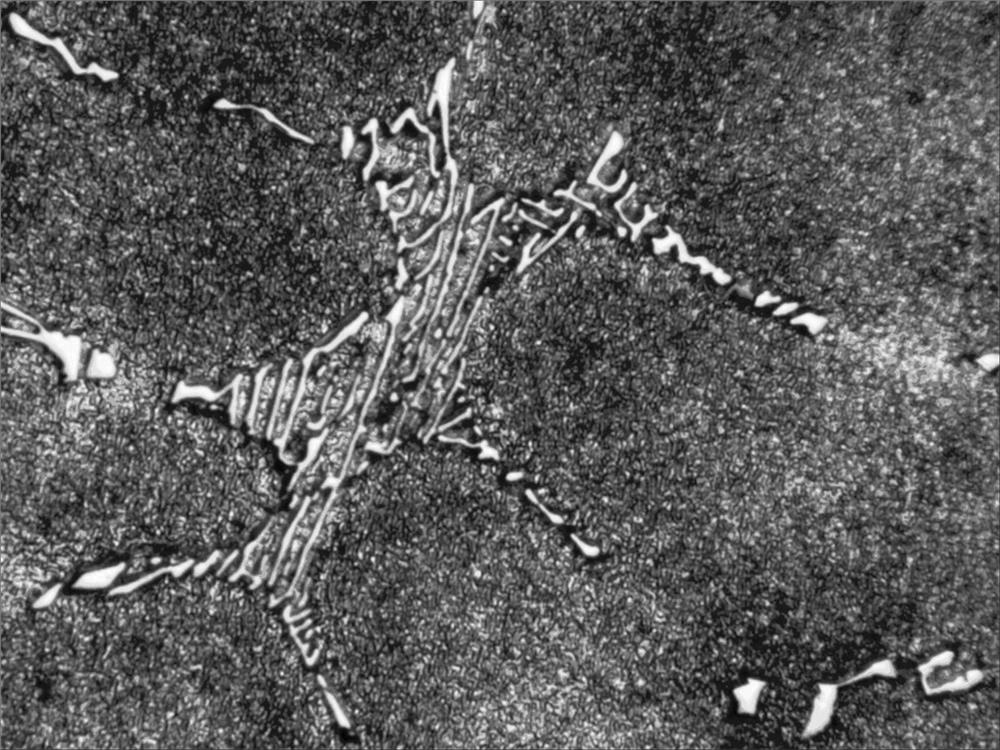

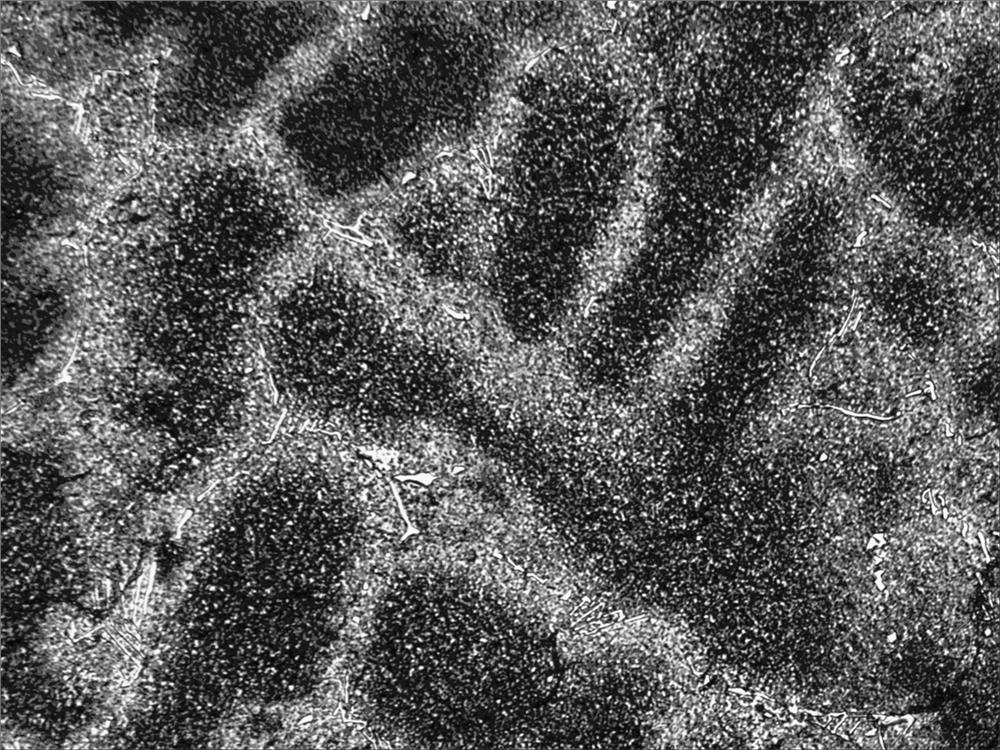

[0019] Example 1: Metallographic etchant for K213 nickel-based alloy (nickel content about 34% to 38%) and the method of use are as follows:

[0020] Corrosive agent preparation: Weigh 5g of ferric chloride and 3g of copper chloride at room temperature and put them into a dry and clean beaker; pour 100ml of concentrated hydrochloric acid with a volume percentage of 36.5%, and continue stirring with a glass rod; then pour in a volume percentage of 95% % anhydrous ethanol 100ml, continue to stir with a glass rod until the solid powder is completely dissolved; let it stand for at least 5min.

[0021] Sample preparation: Use a cutting machine to cut metallographic samples of K213 nickel-based alloys; use grinding wheels or coarse sandpaper to chamfer each side and edge of the samples; use metallographic water sandpaper of different sizes to grind the samples, The sample was ground successively by 220 mesh, 400 mesh, 800 mesh and 1000 mesh metallographic water sandpaper; the sample...

Embodiment 2

[0023] Example 2: The metallographic etchant for K418 nickel-based alloy (with a nickel content of about 72% to 76%) and the method of use are as follows.

[0024] Corrosive agent preparation: Weigh 5g of ferric chloride and 3g of copper chloride at room temperature and put them into a dry and clean beaker; pour 100ml of concentrated hydrochloric acid with a volume percentage of 36.5%, and continue stirring with a glass rod; then pour in a volume percentage of 95% Add 50ml of absolute ethanol, stir continuously with a glass rod until the solid powder is completely dissolved; let stand for at least 5min.

[0025] Sample preparation: use a cutting machine to cut metallographic samples of K418 nickel-based alloy; use grinding wheels or coarse sandpaper to chamfer each side and edge of the sample; use metallographic water sandpaper of different particle sizes to grind the sample, metallographic The sample was ground successively by 220 mesh, 400 mesh, 800 mesh and 1000 mesh metall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com