Method for detecting poloxamer residual quantity in recombinant human urokinase raw material for injection

A detection method, poloxamer technology, applied in the field of detection and analysis, can solve problems such as increasing the difficulty of optimization and difficult separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

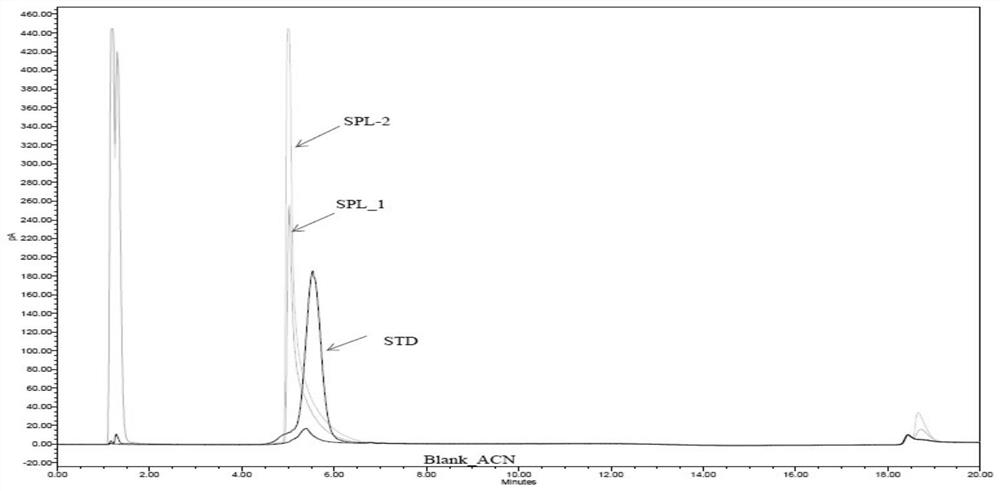

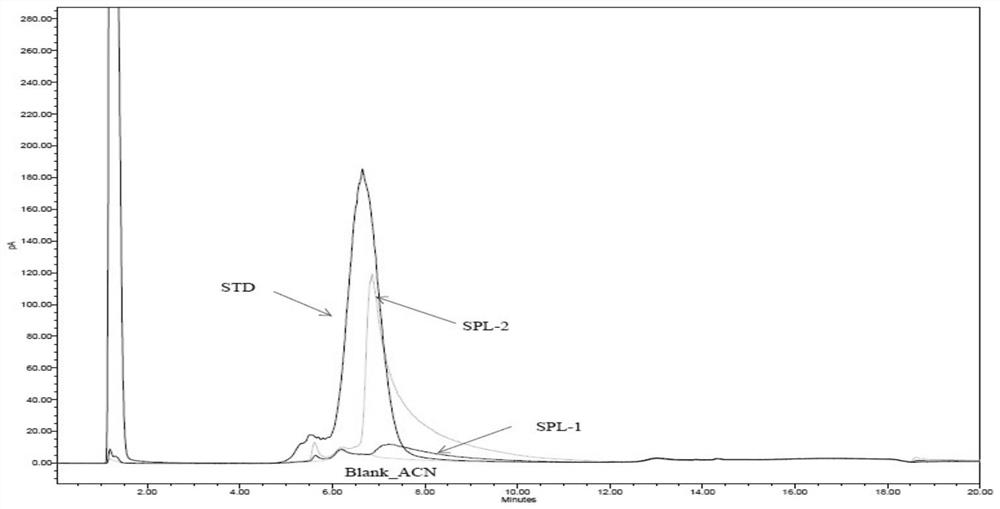

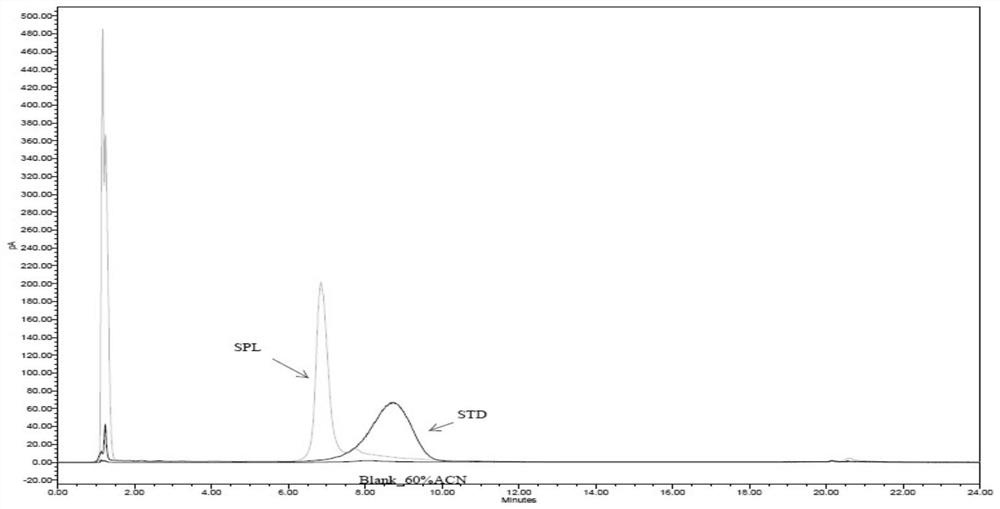

[0089] Example 1: A method for detecting the residual amount of poloxamer in the raw material of recombinant human urokinase for injection

[0090] Sample pretreatment method: Add 200 μl of original sample to 300 μl of acetonitrile that has been frozen overnight, shake for 30 seconds, sonicate for 3 minutes, shake again for 30 seconds, centrifuge at 9500 rpm for 1 minute, and take the supernatant.

[0091] Standard solution preparation method: Take poloxamer standard, weigh and prepare standard solution, the concentration is 2mg / ml, 1mg / ml, 0.5mg / ml, 0.25mg / ml, 0.1mg / ml, 0.04mg / ml, 0.02mg / ml, 0.01mg / ml, 0.005mg / ml.

[0092] Chromatographic conditions (HPLC-CAD): column Acclaim TM Surfactant Plus column, 3μm, 30mm×150mm; injection volume 10μL; column temperature 40℃; flow rate 0.7mL / min; CAD detector: sampling frequency 5 Hz, peak filtration time parameter 3.6 seconds, nebulization temperature 50℃; mobile phase and gradient elution are shown in Table 1.

[0093]Detection: ...

Embodiment 2

[0094] Embodiment 2: verification of the method

[0095] 1. Preparation of samples and solutions:

[0096] 1.1 Standards and samples

[0097] Standard product: F68 (STD), Sigma, batch number SLBP3447V;

[0098] Sample 1: recombinant human urokinase stock solution for injection (SPL1), Shanghai Tasly, batch number T20161219B;

[0099] Sample 2: Recombinant human pro-urokinase stock solution for injection (SPL2), Shanghai Tasly, batch number V20170526B.

[0100] Blank sample: a sample not containing F68 and recombinant human prourokinase, 60% acetonitrile (Blank).

[0101] 1.2 Preparation of sample solution

[0102] Stock#1 solution (2mg / mL): Accurately weigh 10.84mg of F68 into a 5mL volumetric flask, add 3mL of diluent, dilute to the mark with diluent, and mix well;

[0103] Stock#2 solution (2mg / mL): Accurately weigh 10.38mg of F68 into a 5mL volumetric flask, add 3mL of diluent, dilute to the mark with diluent, and mix well;

[0104] L8 solution (2mg / mL): take stock#2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com