Recycled fine aggregate aerated building block with electromagnetic wave absorption performance and preparation method thereof

A technology for regenerating fine aggregates and aerated blocks, applied in the field of building materials, can solve the problems that ordinary blocks cannot meet the use function, consume a lot of resources and energy, occupy a large amount of land, etc., and achieve excellent thermal insulation and electromagnetic wave absorption performance. ,Convenient construction, obvious effect of absorbing wave

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

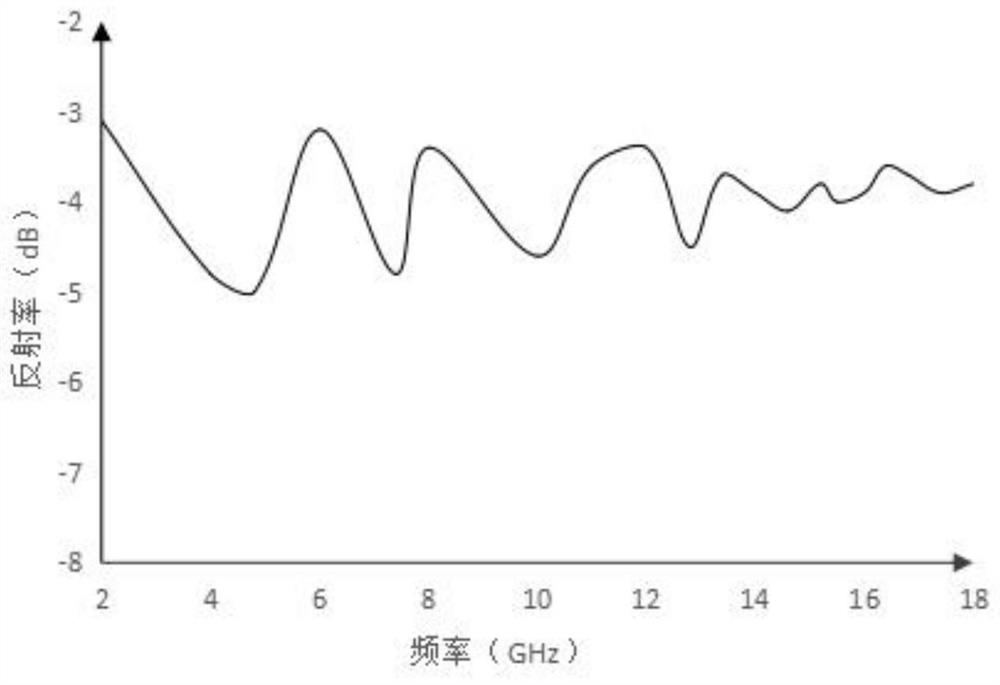

Embodiment 1

[0026] 100 parts of recycled concrete aggregate fine powder, 50 parts of sand, 75 parts of cement, 30 parts of lime, 0.5 parts of graphite, 0.5 parts of carbon black, 30 parts of lightweight aggregate, 1.6 parts of polyurethane thermal slag, 0.01 parts of industrial carbon nanotubes, 30 parts of steel slag powder, 0.4 parts of aluminum powder, 0.7 parts of carbon fiber, 3 parts of dispersant water glass, 400 parts of water.

[0027] The above-mentioned preparation method of the regenerated fine aggregate aerated block with electromagnetic wave-absorbing properties comprises the following steps:

[0028] (1) Stir the recycled concrete aggregate fine powder, sand, cement, lime, lightweight aggregate, polyurethane hot slag, steel slag powder, and carbon fiber according to the metering ratio to obtain the mixed dry material;

[0029] (2) Add carbon black, aluminum powder, industrial carbon nanotubes, and graphite into water of 1 / 2 to 2 / 3 of the required amount and stir evenly to o...

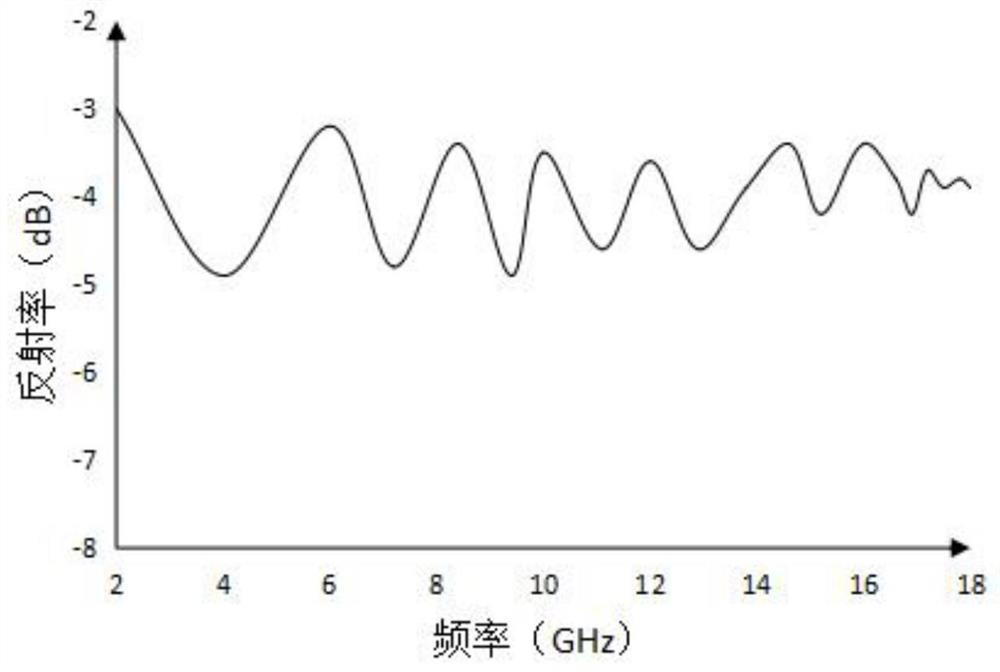

Embodiment 2

[0033] A regenerated fine aggregate aerated block with electromagnetic wave-absorbing properties, which includes the following raw materials in parts by weight: 150 parts of recycled concrete aggregate fine powder, 60 parts of sand, 80 parts of cement, 35 parts of lime, 0.6 part of graphite, 0.6 parts of carbon black, 25 parts of lightweight aggregate, 1.4 parts of polyurethane thermal slag, 0.01 part of industrial carbon nanotubes, 25 parts of steel slag powder, 0.4 parts of aluminum powder, 0.75 parts of carbon fiber, 3.5 parts of dispersant water glass, 380 parts of water.

[0034] The above-mentioned preparation method of the regenerated fine aggregate aerated block with electromagnetic wave-absorbing properties comprises the following steps:

[0035] (1) Stir cement, recycled concrete aggregate fine powder, lime, lightweight aggregate, polyurethane hot slag, steel slag powder, and carbon fiber according to the metering ratio to obtain a mixed dry material;

[0036] (2) Ad...

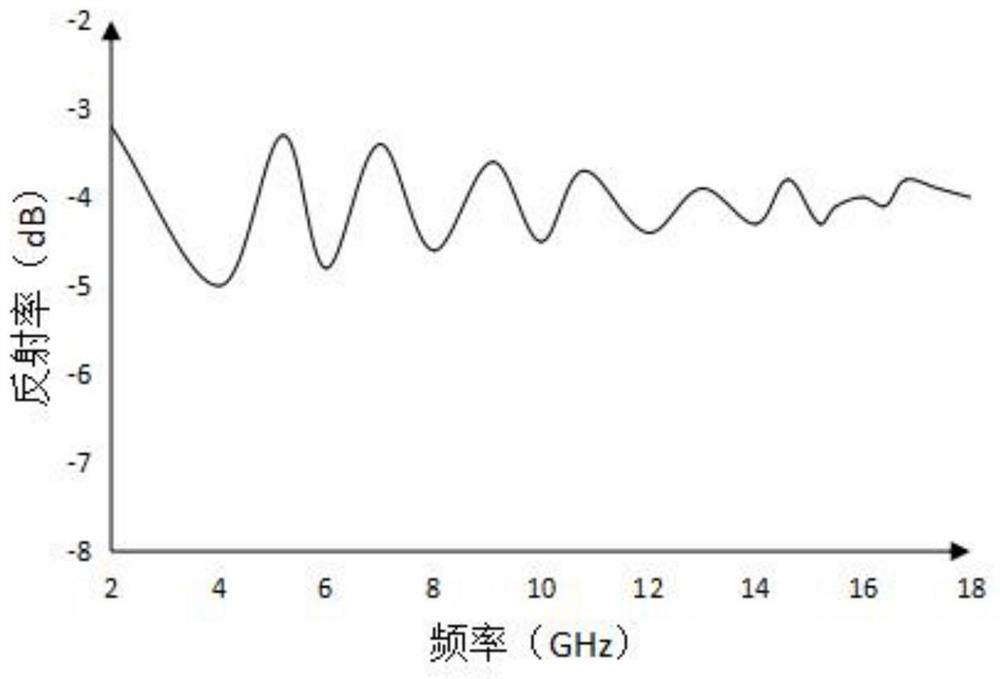

Embodiment 3

[0040] A regenerated fine aggregate aerated block with electromagnetic wave-absorbing properties, which includes the following raw materials in parts by weight: 180 parts of recycled concrete aggregate fine powder, 70 parts of sand, 85 parts of cement, 40 parts of lime, 0.65 parts of graphite, 0.7 parts of carbon black, 25 parts of lightweight aggregate, 1.2 parts of polyurethane thermal slag, 0.01 part of industrial carbon nanotubes, 25 parts of steel slag powder, 0.4 parts of aluminum powder, 0.80 parts of carbon fiber, 4 parts of dispersant water glass, 380 parts of water.

[0041] The preparation method of the regenerated fine aggregate aerated block with electromagnetic wave-absorbing properties is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com