Method for preparing zirconium oxide-doped gadolinium niobate amorphous high-temperature ceramic coating

A high-temperature ceramic and ceramic coating technology, applied in the coating, metal material coating process, ion implantation plating and other directions, can solve the thermal barrier coating ceramic material peeling failure, thermal expansion coefficient mismatch, difficult to meet the inlet temperature and other problems, to achieve the effects of stable evaporation rate, increased operating temperature, and reduced compositional inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of zirconia-doped gadolinium niobate amorphous high-temperature ceramic coating, comprising the following steps:

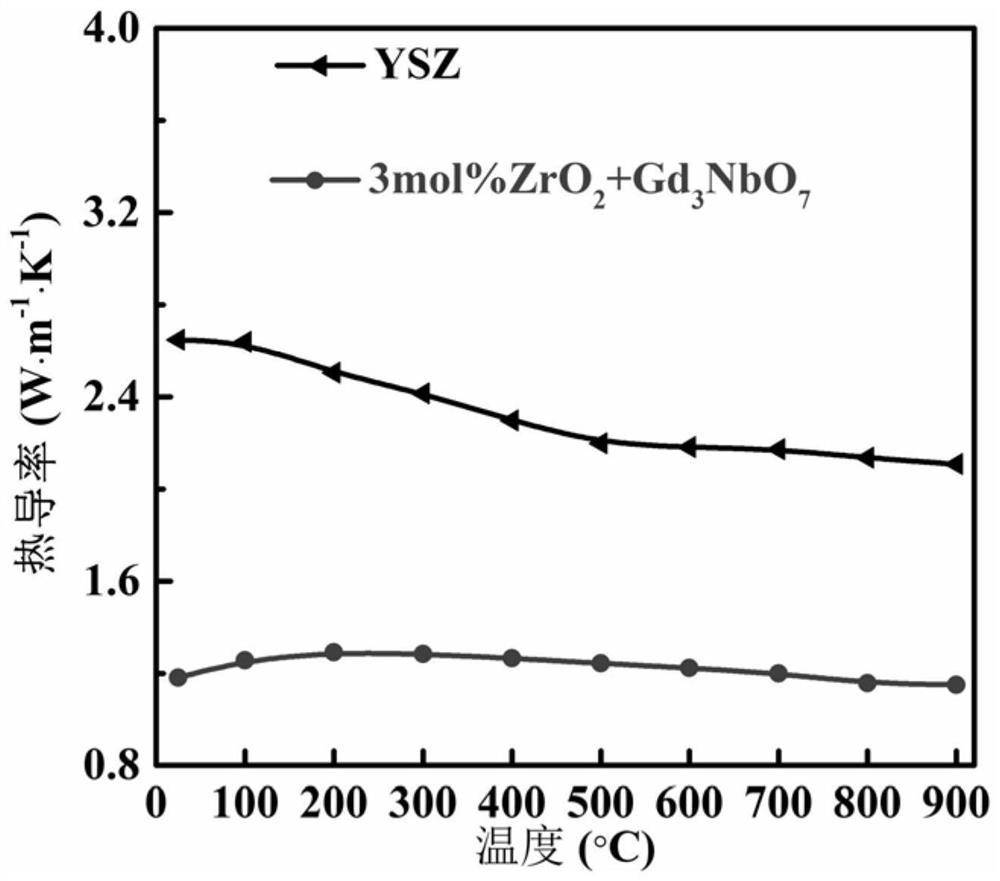

[0033] Step 1: According to 3mol% ZrO 2 +Gd 3 NbO 7 The stoichiometric ratio was weighed ZrO 2 、Gd 2 o 3 and Nb 2 o 5 The powder is mixed evenly by a ball mill, wherein the speed of the ball mill is 500r / min, and the ball milling time is 120min. The powder after ball milling is dried and passed through a 325 mesh sieve to obtain a powder with uniform particle size, and then sintered at 1400°C for 8h, oxidized Zirconium doped gadolinium niobate sintered body.

[0034] Step 2: crush the sintered body obtained in step 1 into blocks of 2-3 mm.

[0035] Step 3: Deposit the block obtained in Step 2 on the alloy substrate by EB-PVD method to obtain a zirconia-doped gadolinium niobate amorphous ceramic coating, the thickness of the amorphous ceramic coating is 200 μm; wherein the EB-PVD method The process parameters are: the cabin air ...

Embodiment 2

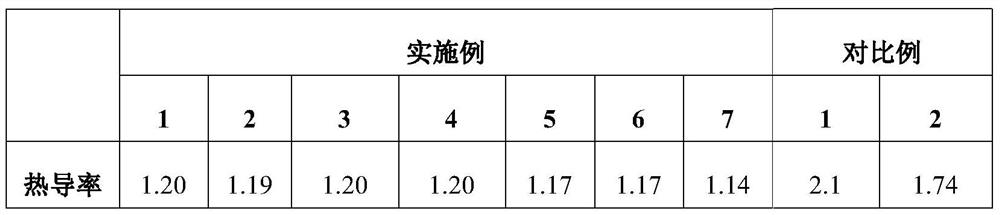

[0039] The only difference between Example 2 and Example 1 is that x=6, that is, the stoichiometric ratio of zirconia-doped niobic acid in Example 2 is 6mol% ZrO 2 +Gd 3 NbO 7 .

Embodiment 3

[0040] The difference between Example 3 and Example 1 is that x=9, that is, the stoichiometric ratio of zirconia-doped niobic acid in Example 3 is 9mol% ZrO 2 +Gd 3 NbO 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com