Lithium supplementing material and preparation method and application thereof

A technology of lithium supplementation and lithium sulfate, which is applied in the field of lithium supplementation, can solve problems such as limited compatibility, and achieve the effects of good compatibility, reasonable cost, and improved cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

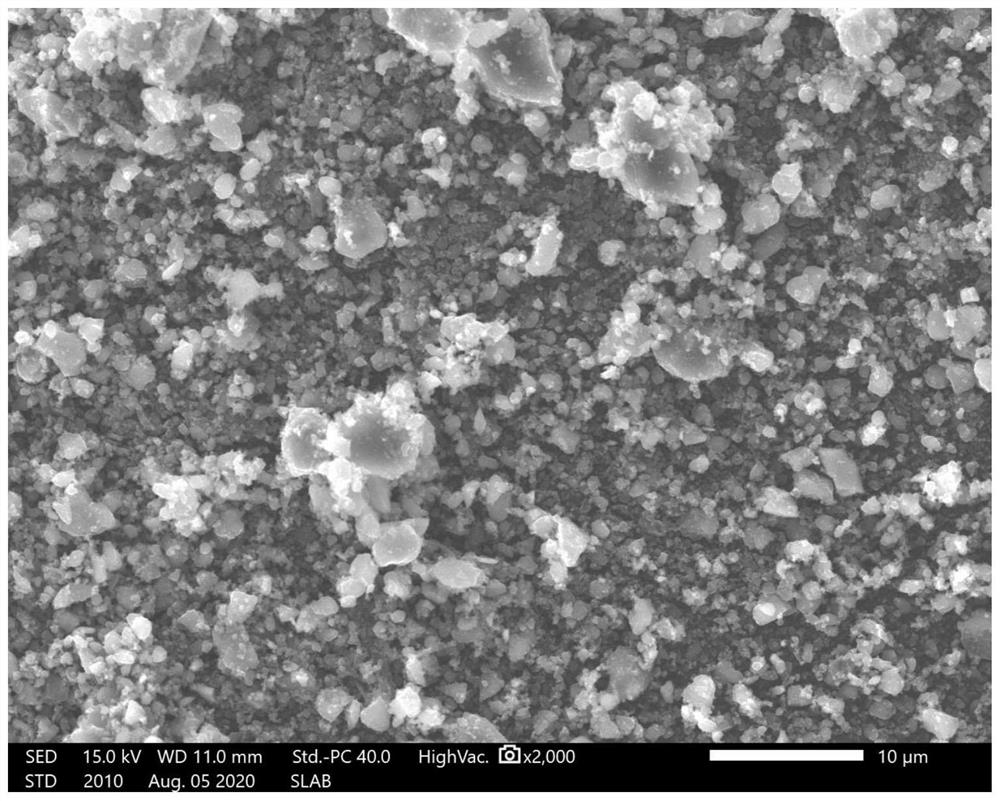

[0038] Embodiment 1: this embodiment uses Li 4 SiO 4 As a lithium-containing compound, MoS 2 As a reducing agent, C 6 h 12 o 6 and C 12 h 22 o 11 As the conductive agent precursor, polyvinylidene fluoride (PVDF) is used as the binder, 1-methyl-2-pyrrolidone (NMP) is used as the solvent, and Super-P is used as the positive electrode conductive additive to make the positive electrode sheet.

[0039] 1. Weigh 3g of NMP into the mixing tank, add 0.1g of PVDF into the NMP, stir well to make it evenly dispersed, and then add 0.64g of Li 4 SiO 4 , 0.16g of MoS 2 And add 0.1g of Super-P into the mixing tank, stir again to disperse evenly, then evenly coat the slurry on the surface of aluminum foil, and dry it in an oven at 55°C for 6h. The dried pole pieces were punched into discs with a diameter of 12mm, and transferred to a vacuum oven at 120°C for 6 hours. After the temperature dropped to room temperature, the pole pieces were quickly transferred into a glove box filled w...

Embodiment 2

[0049] Embodiment 2: this embodiment uses Li 4 SiO 4 As a lithium-containing compound, MoS 2 As a reducing agent, C 6 h 12 o 6 As the conductive agent precursor, polyvinylidene fluoride (PVDF) is used as the binder, 1-methyl-2-pyrrolidone (NMP) is used as the solvent, and Super-P is used as the positive electrode conductive additive to make the positive electrode sheet.

[0050] 1. Mix 1g Li 4 SiO 4 , 1g C 6 h 12 o 6 After mixing, put it into a tube furnace, and fire at 700°C with argon gas at high temperature for 6 hours, control the thickness of the coated carbon layer at 30nm, and then add 0.2gMoS 2 After mixing evenly, put it into an airtight container and heat it in a vacuum oven at 120°C for 4 hours to obtain a lithium-replenishing material. Weigh 3g of NMP into the mixing tank, add 0.1g of PVDF into the NMP, stir well to make it evenly dispersed, then add 0.8g of lithium supplement material and 0.1g of Super-P into the mixing tank, stir again to make it evenly...

Embodiment 3

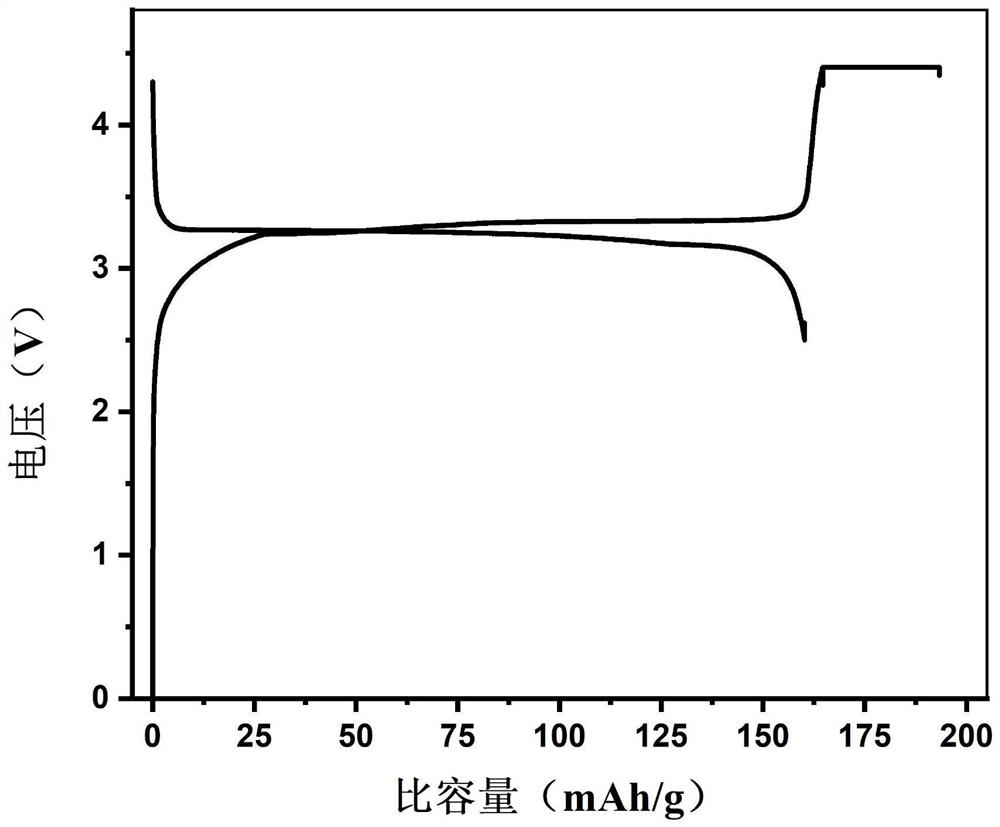

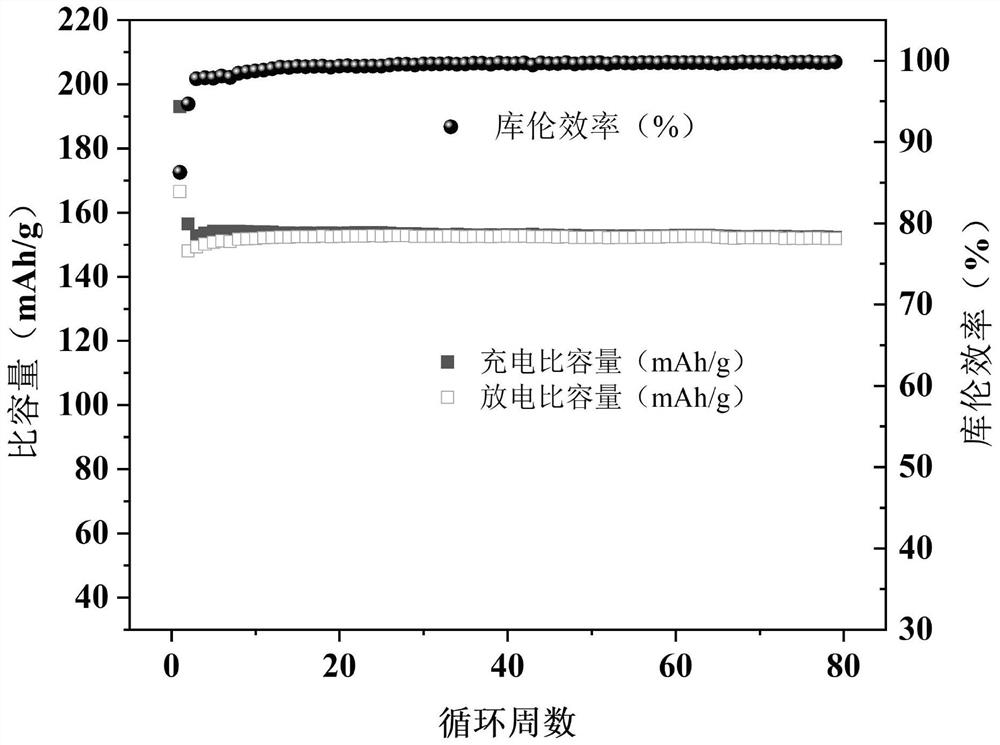

[0057] Embodiment 3: This embodiment uses LiFePO 4 As the cathode material, Li 4 SiO 4 As a lithium-containing compound, MoS 2 As a reducing agent, C 6 h 12 o 6 As the conductive agent precursor, polyvinylidene fluoride (PVDF) is used as the binder, 1-methyl-2-pyrrolidone (NMP) is used as the solvent, and Super-P is used as the positive electrode conductive additive to make the positive electrode sheet. 1g Li 4 SiO 4 with 1g of C 6 h 12 o 6 After mixing, put it into a tube furnace, and fire at 700°C with argon gas at high temperature for 6 hours, control the thickness of the coated carbon layer at 30nm, and then add 0.2gMoS 2 After mixing evenly, put it into an airtight container and heat it in a vacuum oven at 120°C for 4 hours as a lithium supplement material.

[0058] 1. Weigh 3g of NMP into the mixing tank, add 0.05g of PVDF into the NMP, stir well to disperse it evenly, then add 0.9g of LiFePO 4 and 0.05g Super-P were added into the mixing tank, stirred again ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com