Patents

Literature

33results about How to "Reduce charge and discharge polarization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrogen-doped porous carbon material for lithium-air battery positive electrode

ActiveCN103855366AHigh discharge specific capacityHigh voltage platformFuel and secondary cellsCell electrodesPorous carbonCharge discharge

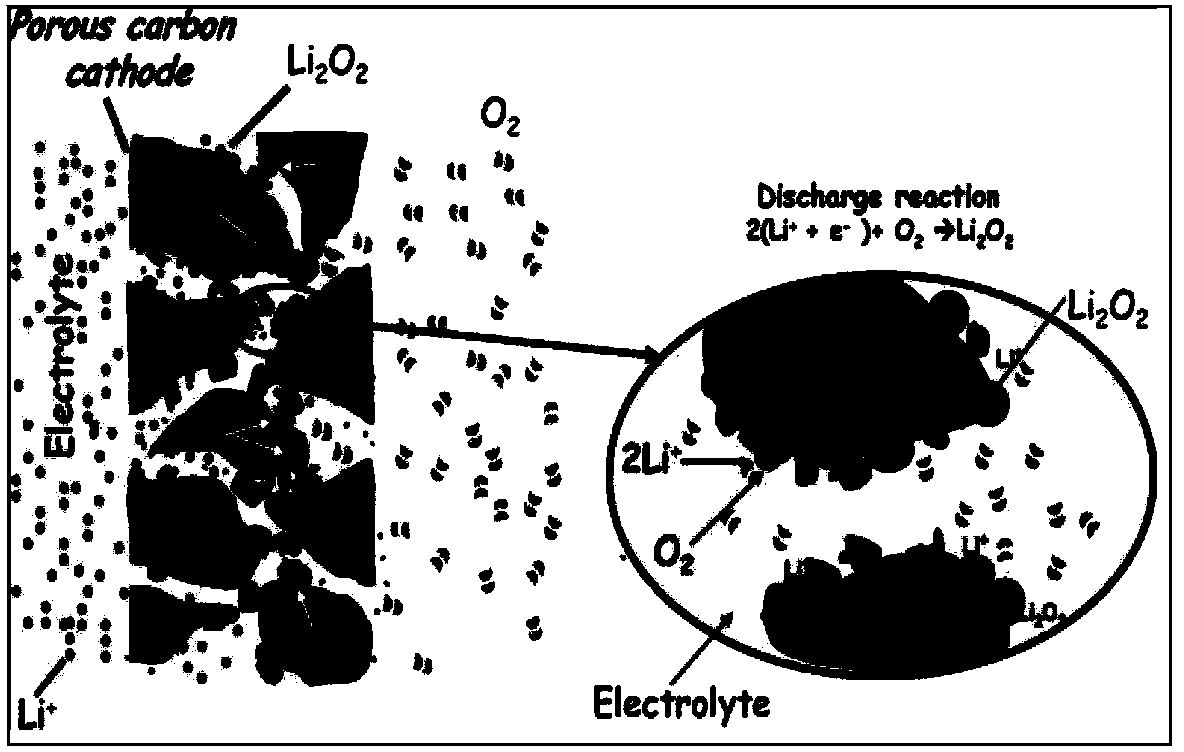

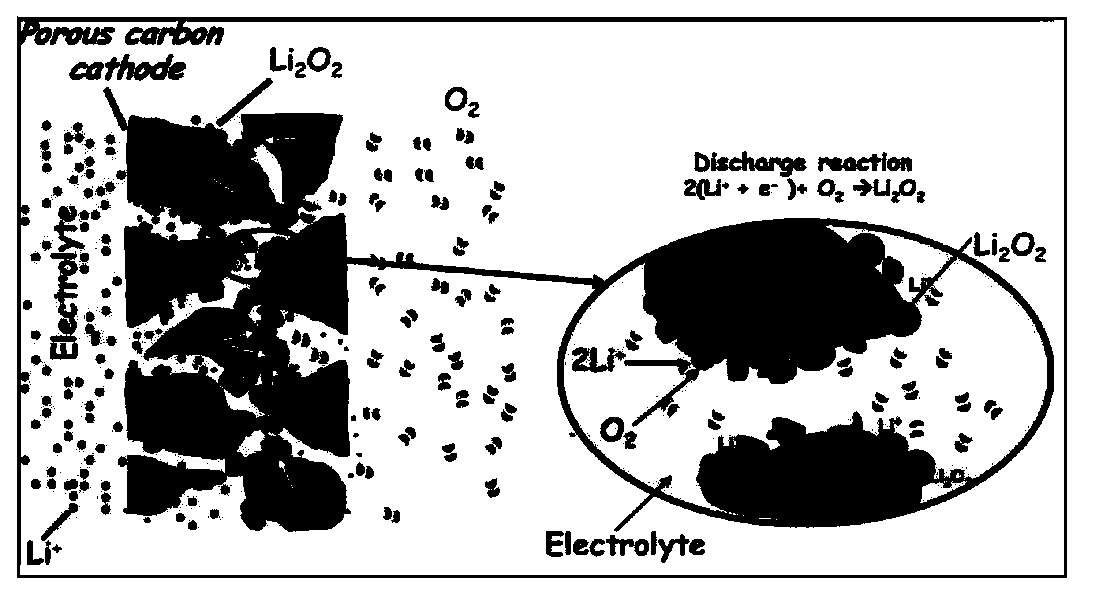

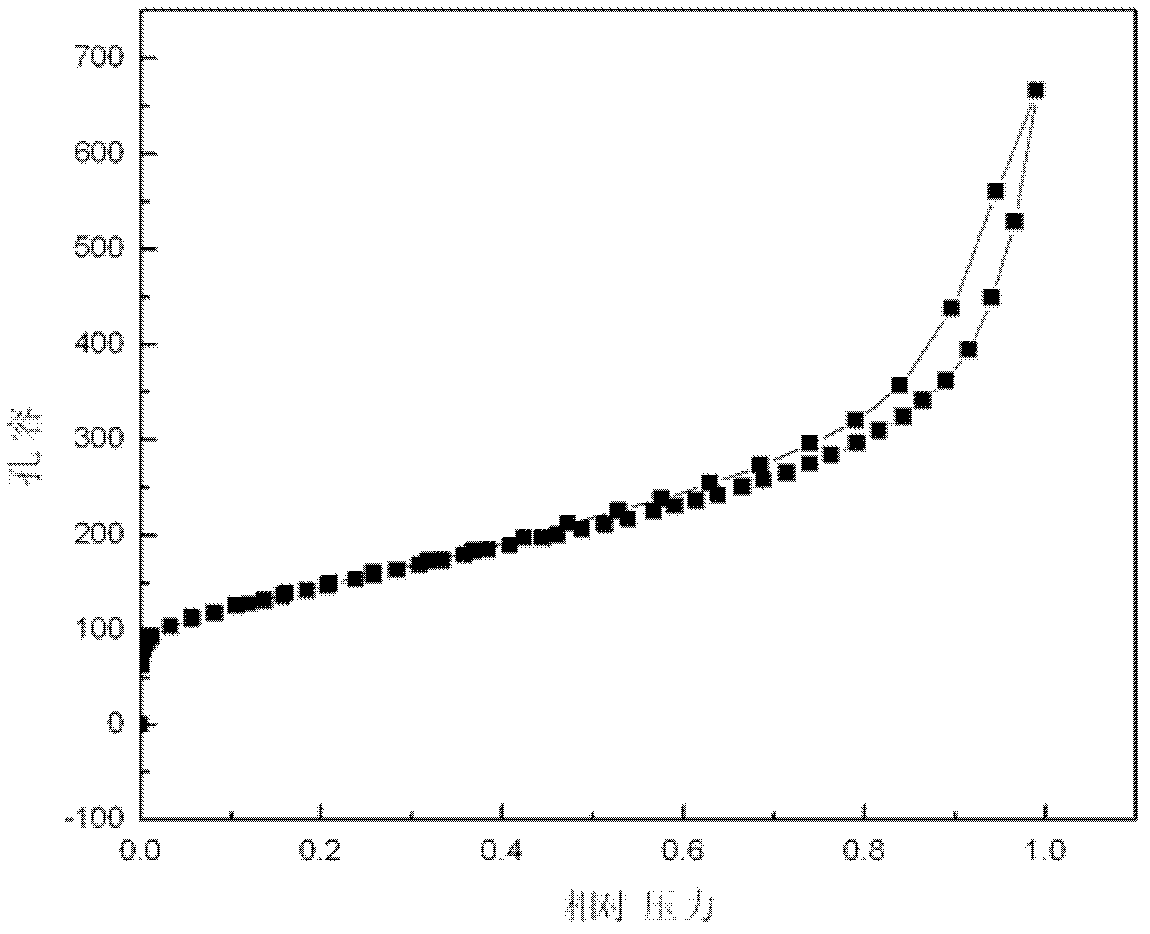

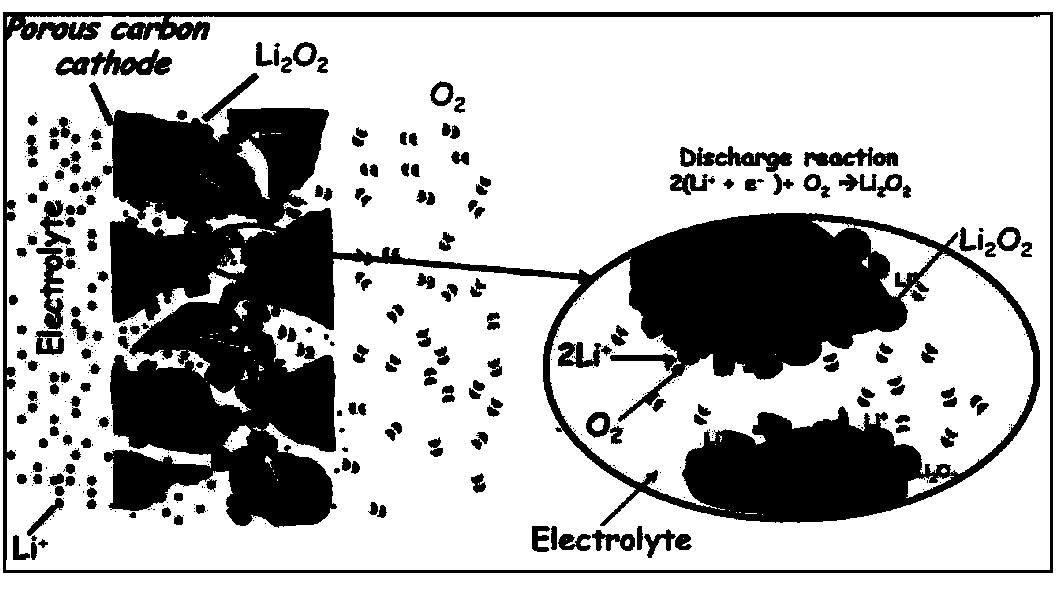

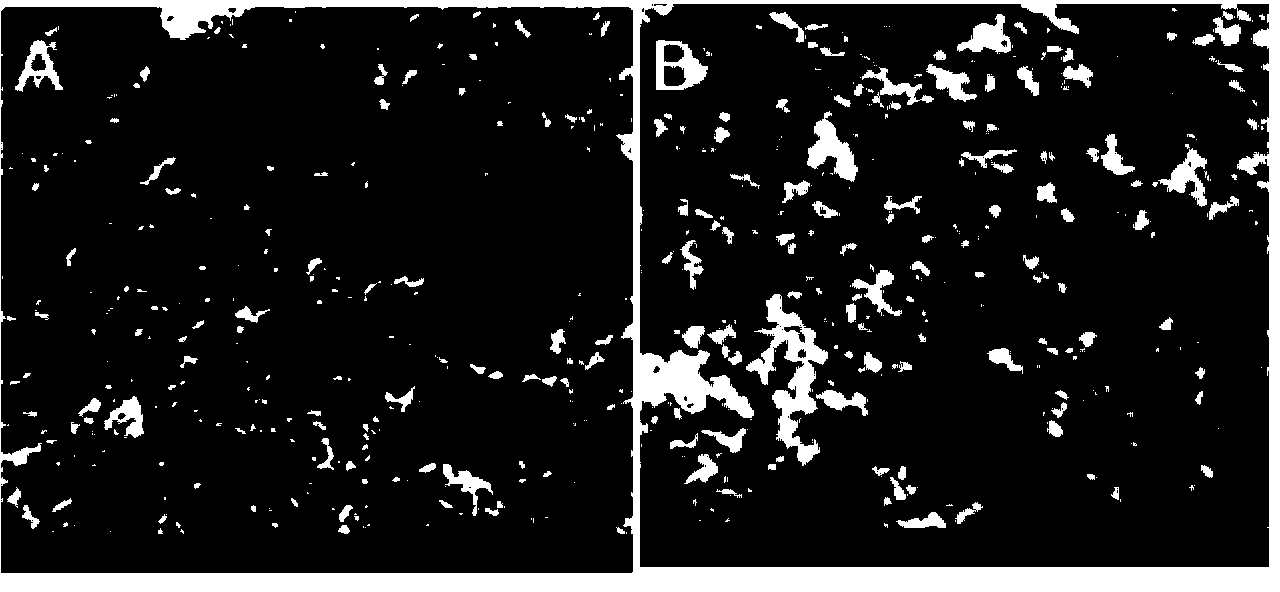

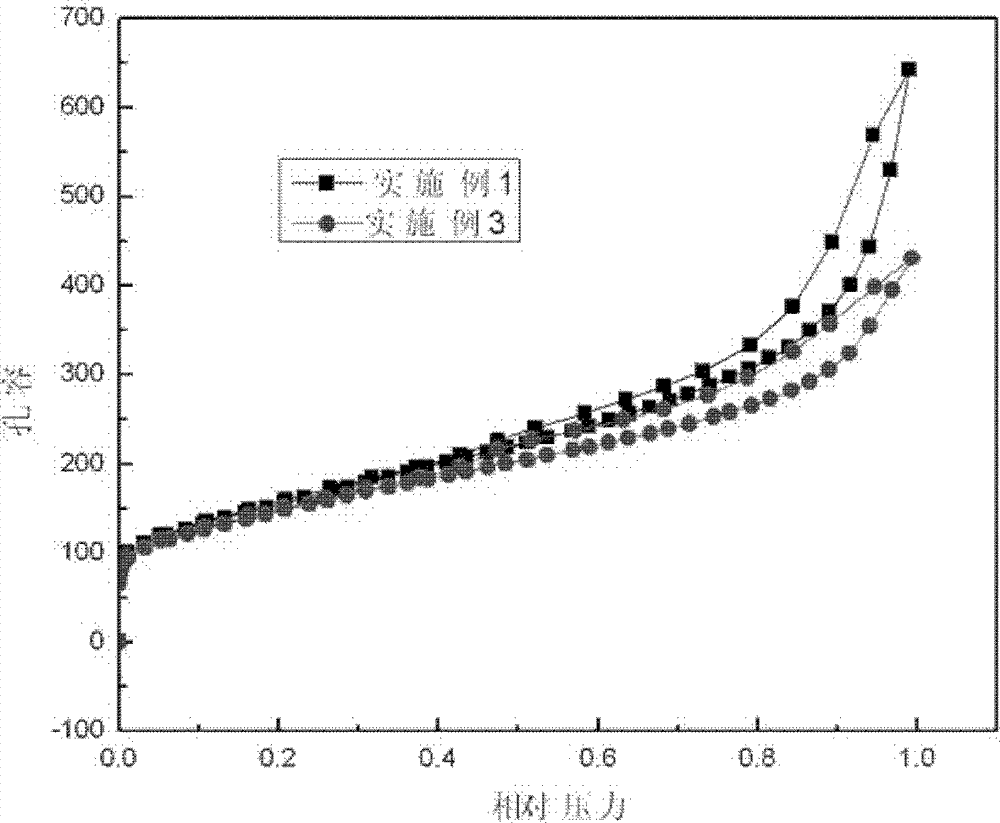

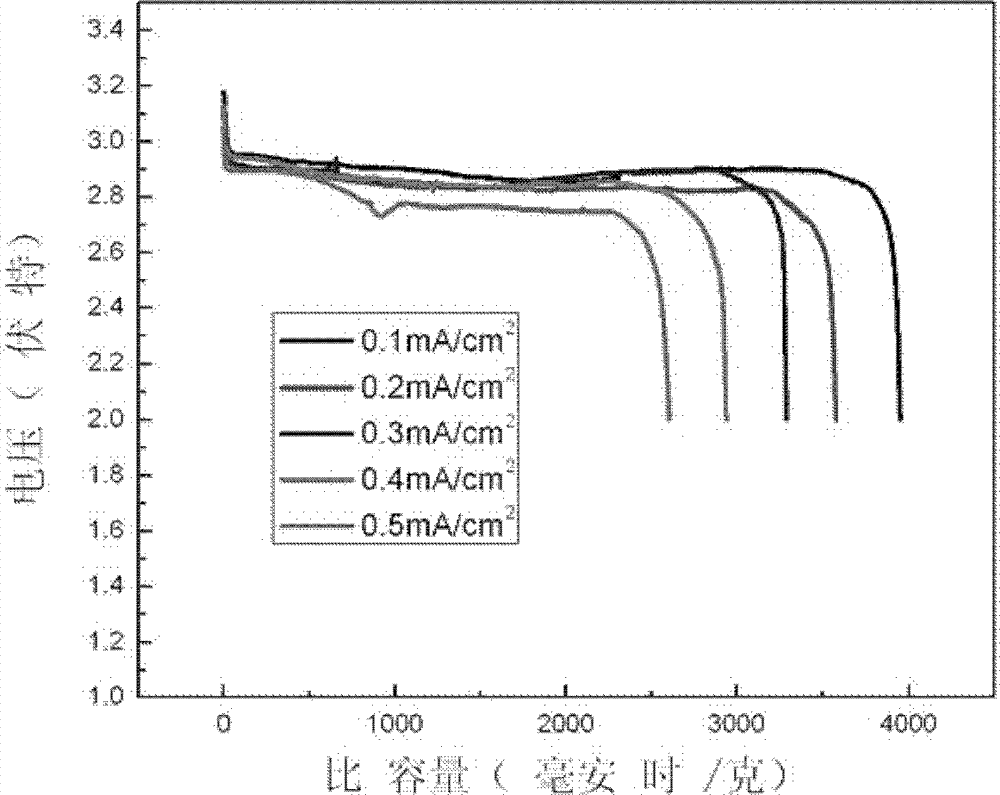

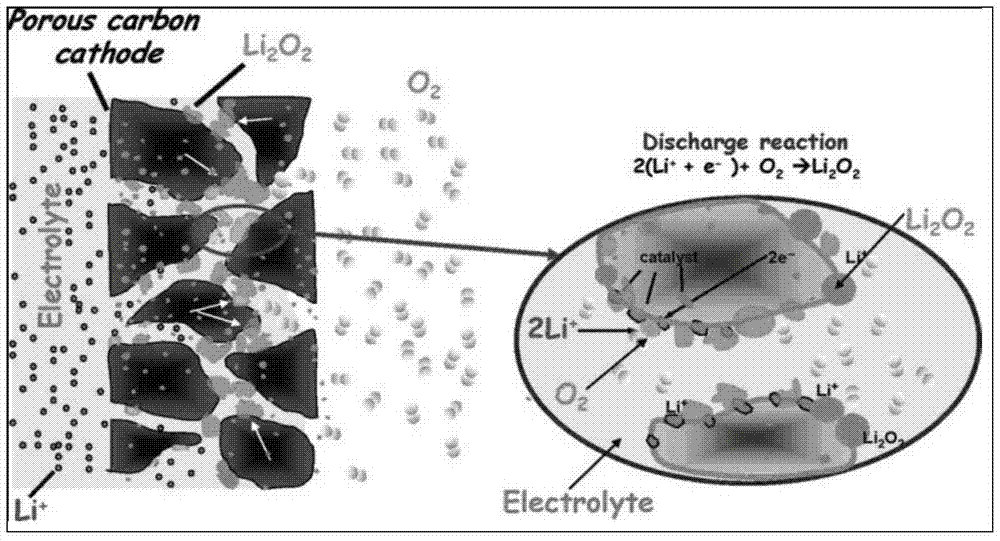

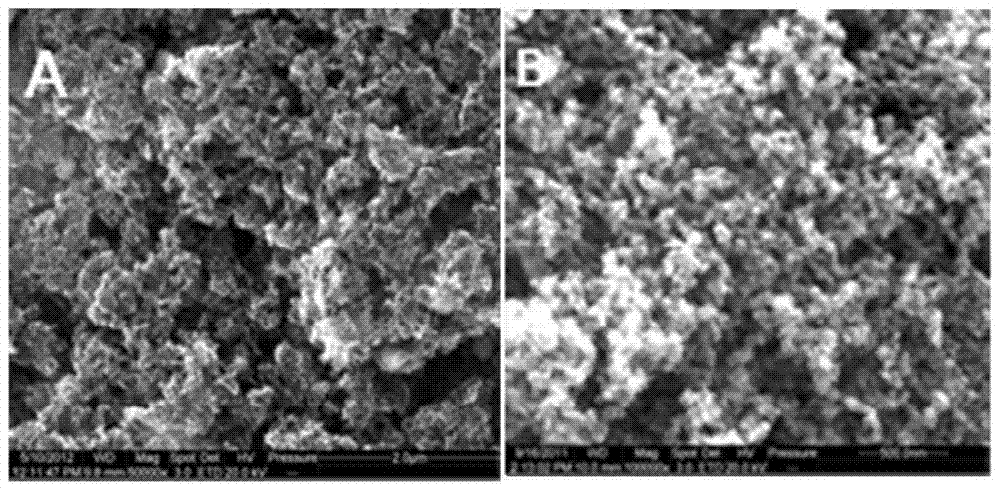

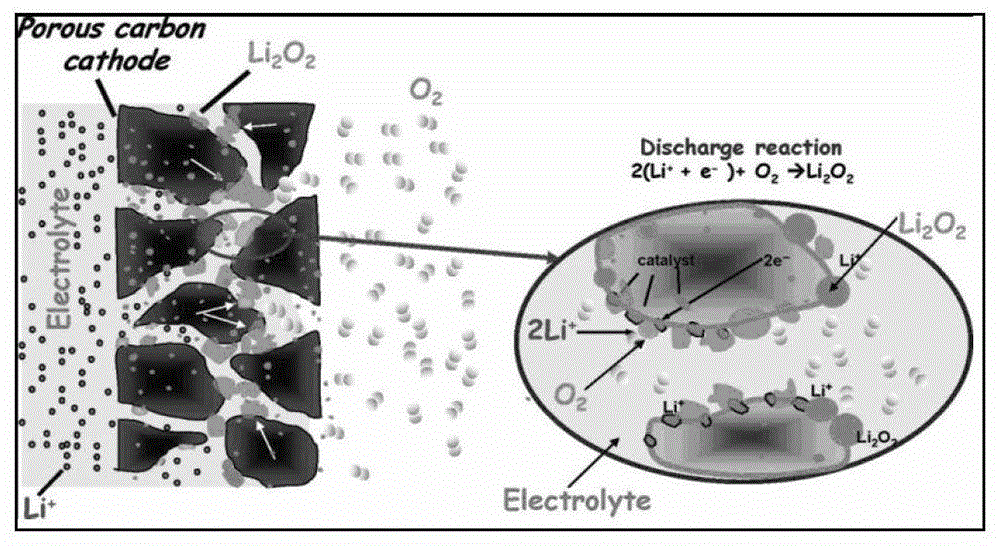

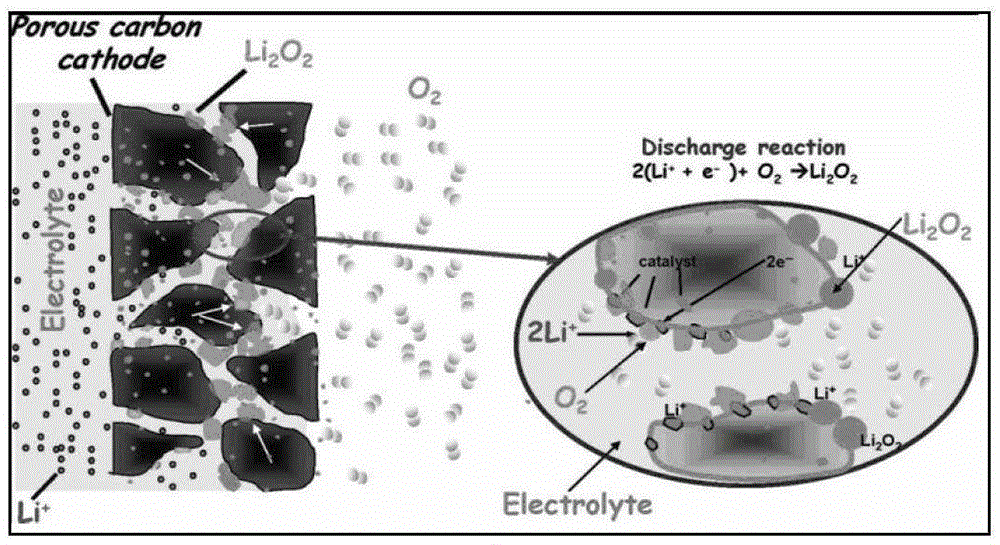

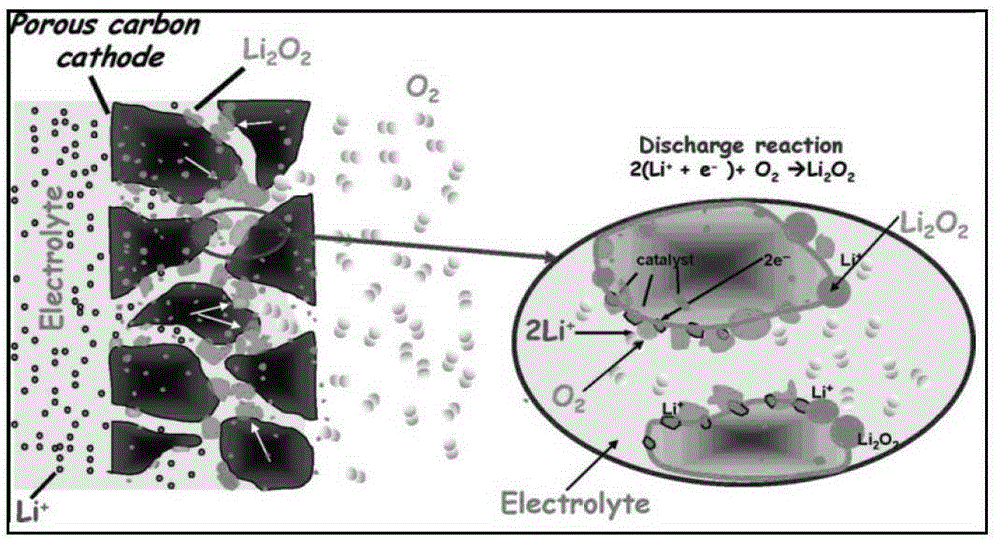

The present invention relates to a nitrogen-doped porous carbon material for a lithium-air battery positive electrode, wherein the nitrogen-doped porous carbon material has an interconnected graded pore structure, N is uniformly doped in the C skeleton, N accounts for 0.2-15% of the carbon material atomic ratio, the graded pores comprise mass transfer pores and deposition holes, the deposition holes account for 40-95% of the total pore volume, and the mass transfer pores account for 4-55% of the total pore volume. According to the present invention, with application of the carbon material as the lithium-air battery electrode material, the space utilization rate of the carbon material during the charge-discharge process can be increased at a maximum, and the energy density and the power density of the lithium-air battery can be effectively increased; and the preparation process is simple, the material source is wide, the pore structure of the graded pore carbon material can be regulated, the regulation manner is diverse, and the nitrogen doping manner is easily achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

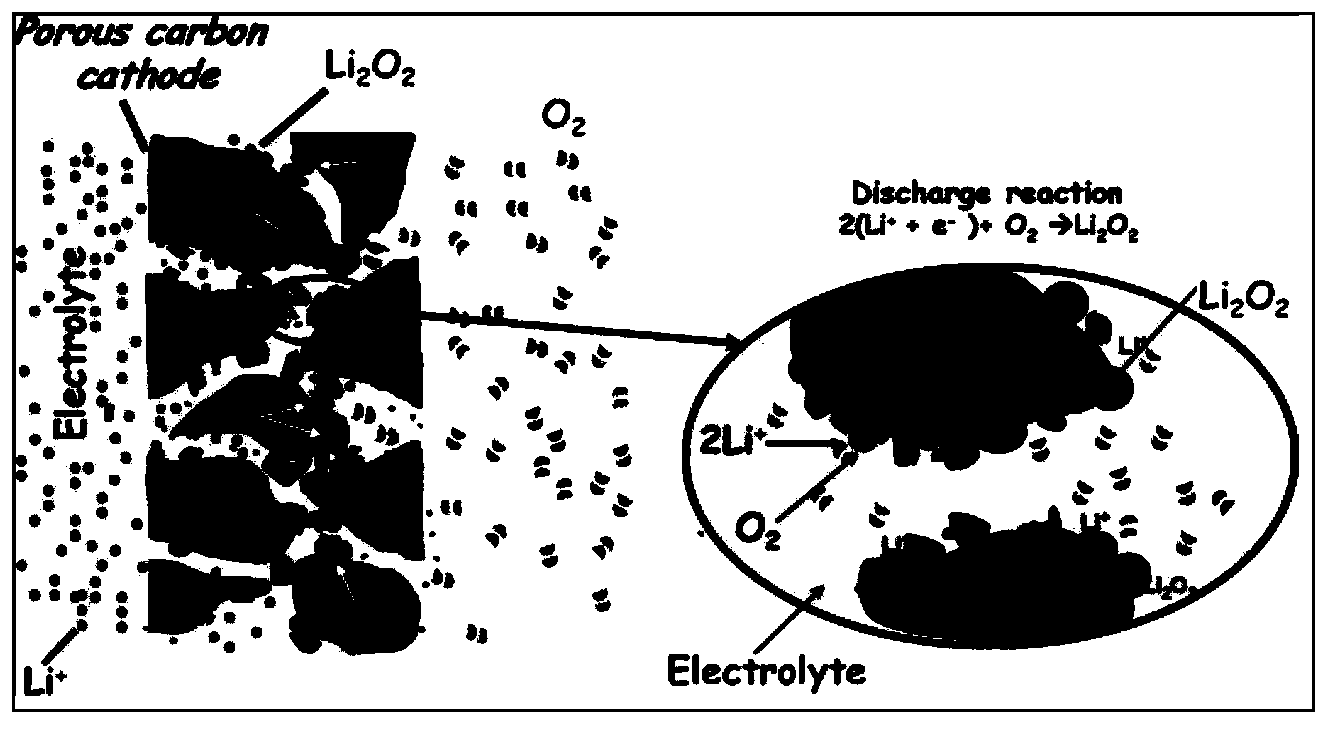

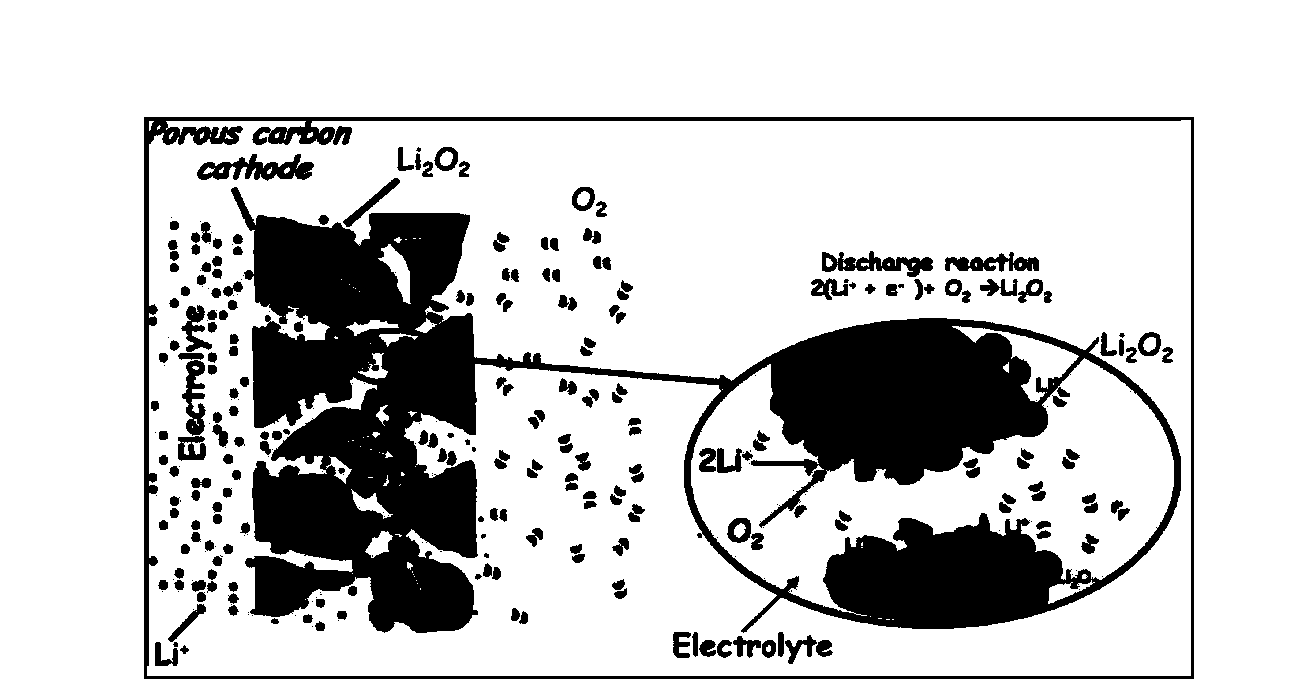

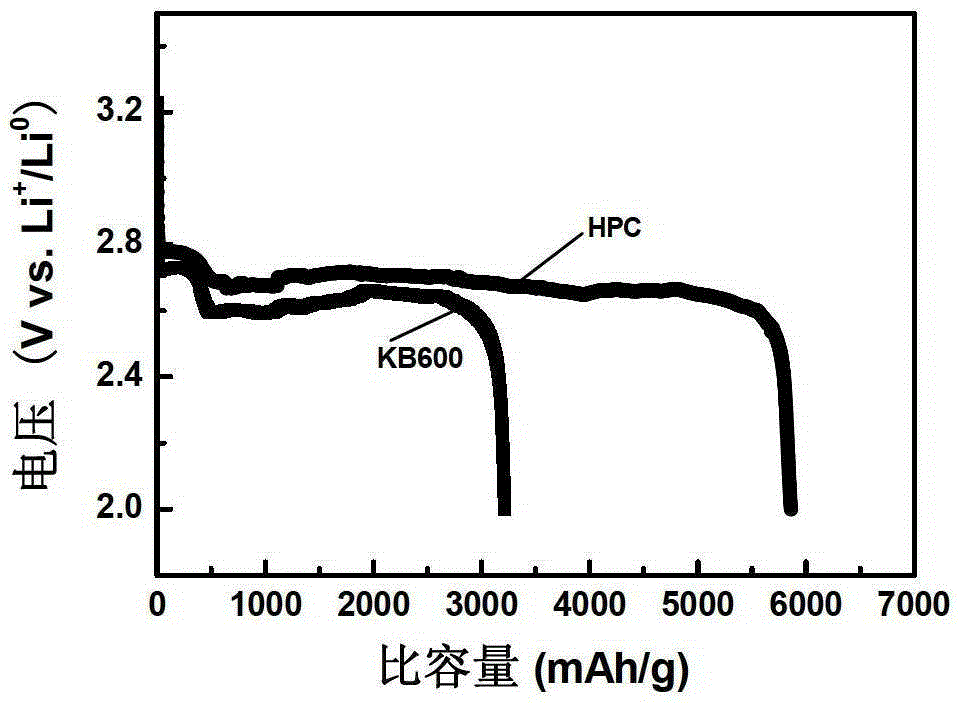

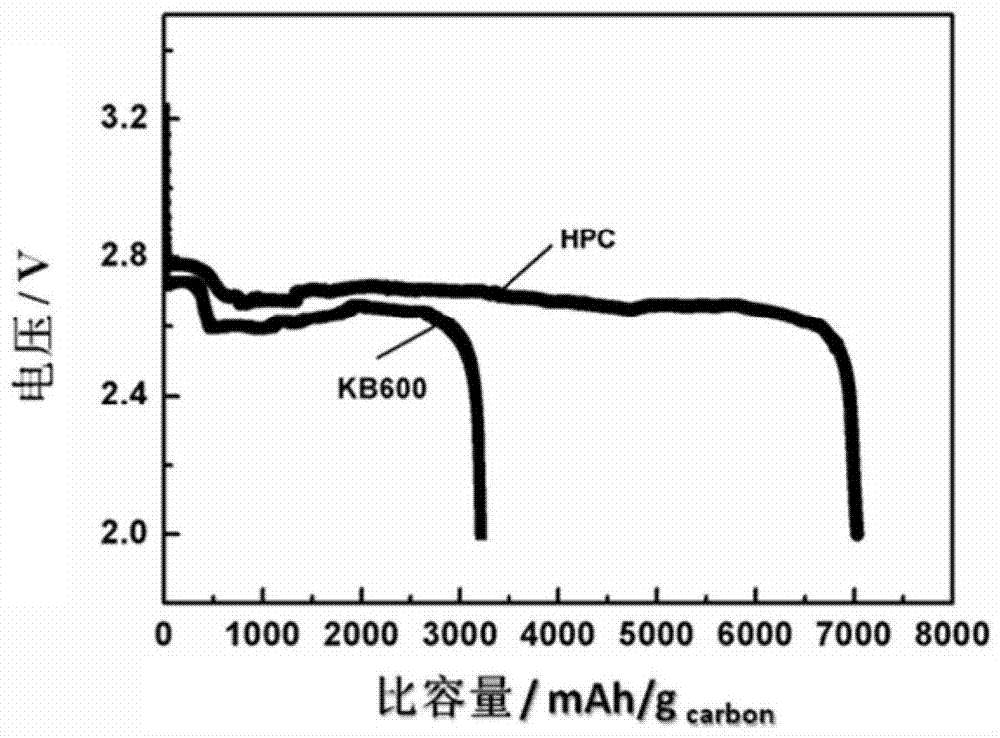

Porous carbon material used for lithium-air cell anode

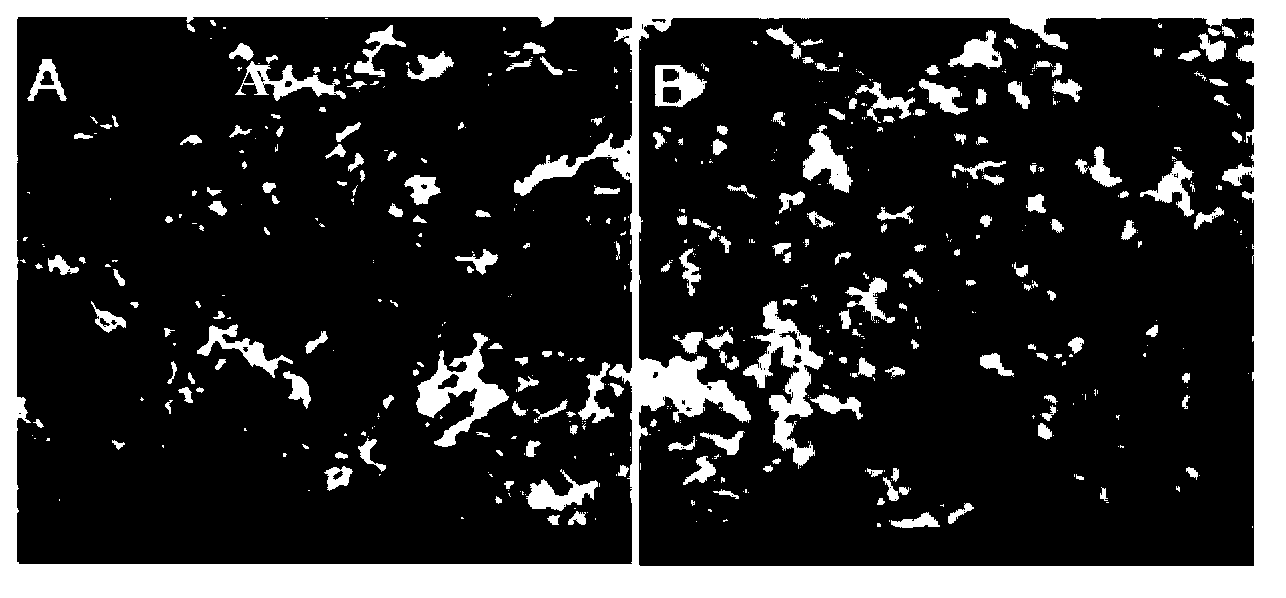

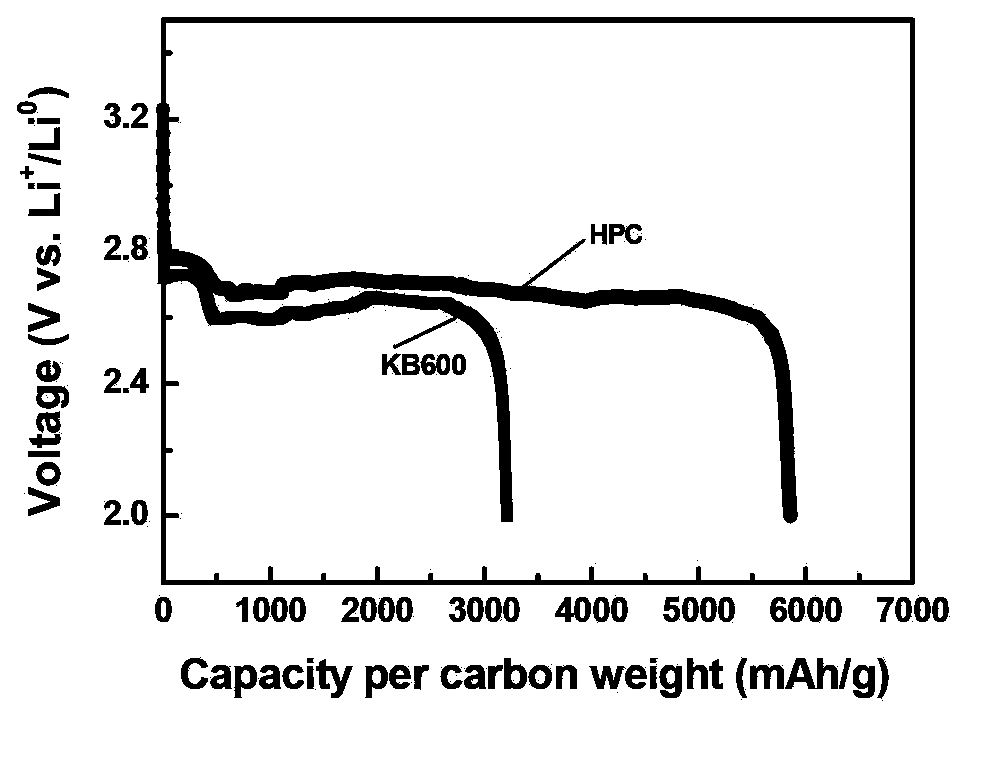

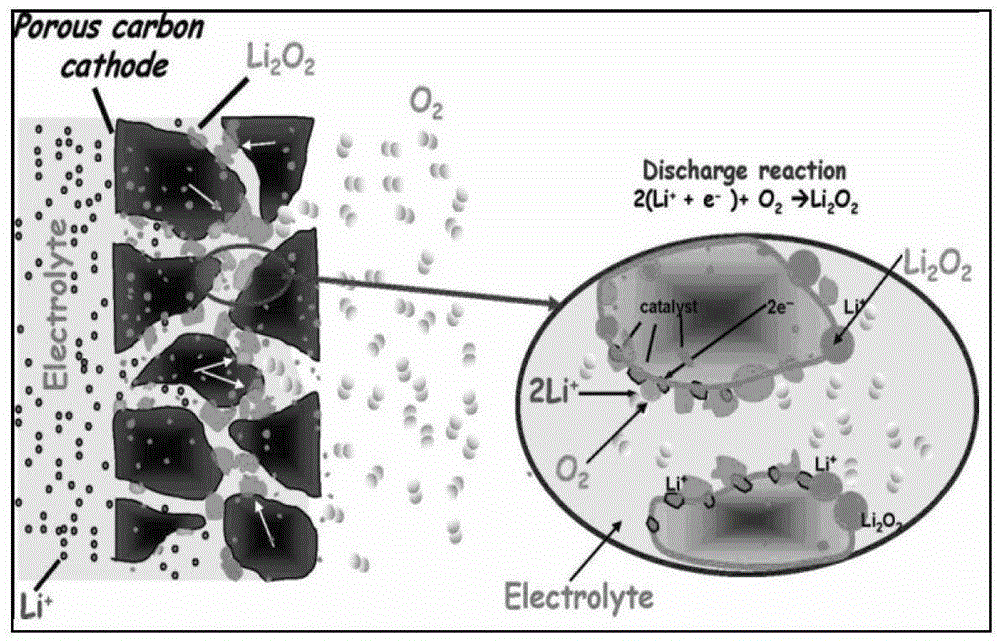

ActiveCN103855413AShorten the diffusion distanceImprove space utilizationFuel and secondary cellsCell electrodesPorous carbonAir cell

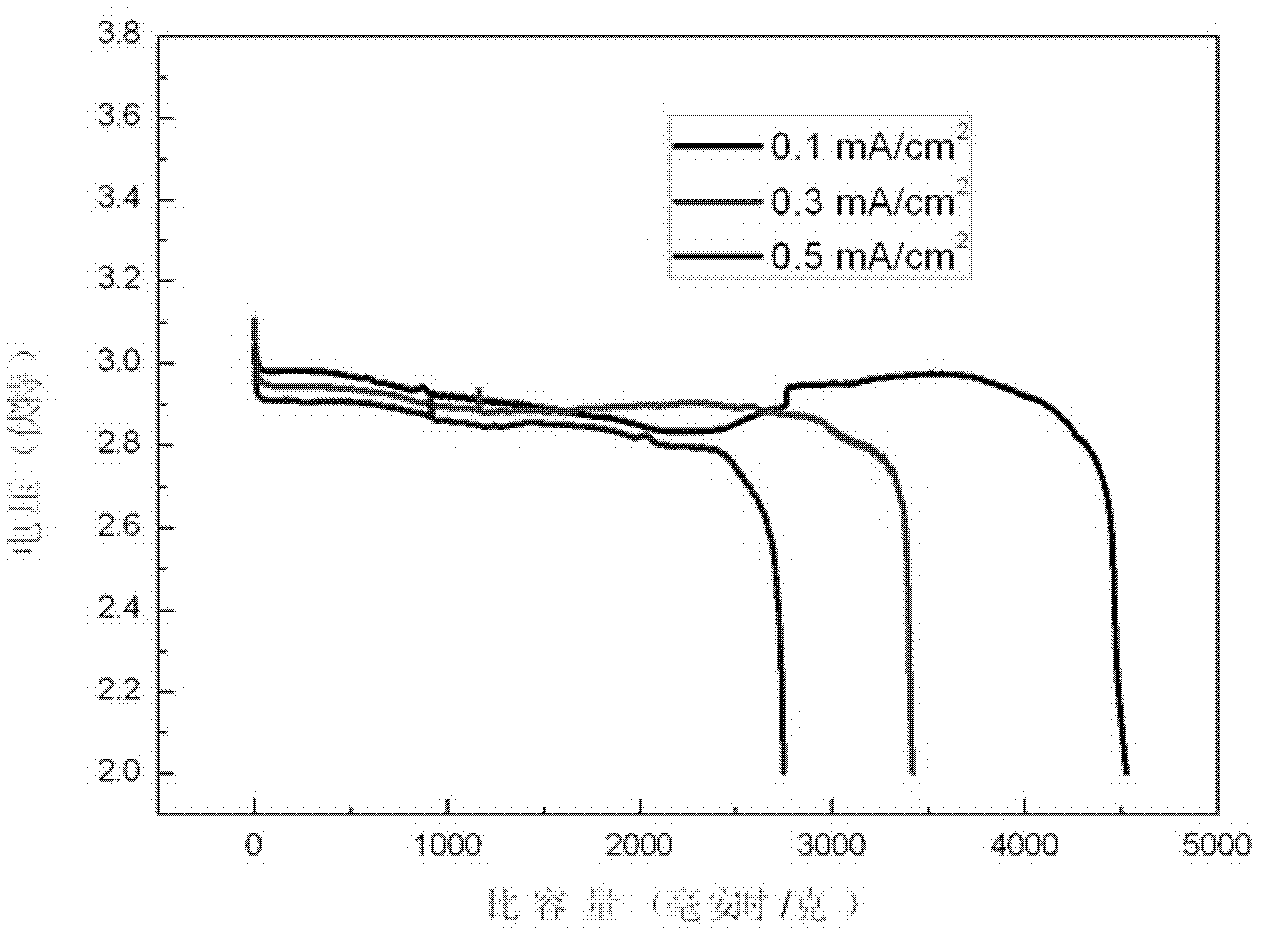

The invention relates to an application of a porous carbon material with a grading pore structure in a lithium-air cell anode, and is characterized in that the carbon material has mutually communicated grading pore structure distribution which has a mesoporous structure for depositing the discharge products and a macroporous structure suitable for transmission of oxygen and an electrolyte. When the carbon material is taken as a material of the lithium-air cell anode, the space utilization rate of carbon material can be increased at maximum limitation during a charge and discharge process, specific discharge capacity, voltage platform and multiplying power discharge capability of the cell can be effectively increased, so that the energy density and power density of the lithium-air cell can be increased. The porous carbon material has the advantages that the preparation technology is simple, the material source is wide, the grading pore carbon material pore structure enables regulation and control, the regulation and control modes are various, and the doping of metal / metal oxide can be easily and simultaneously realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

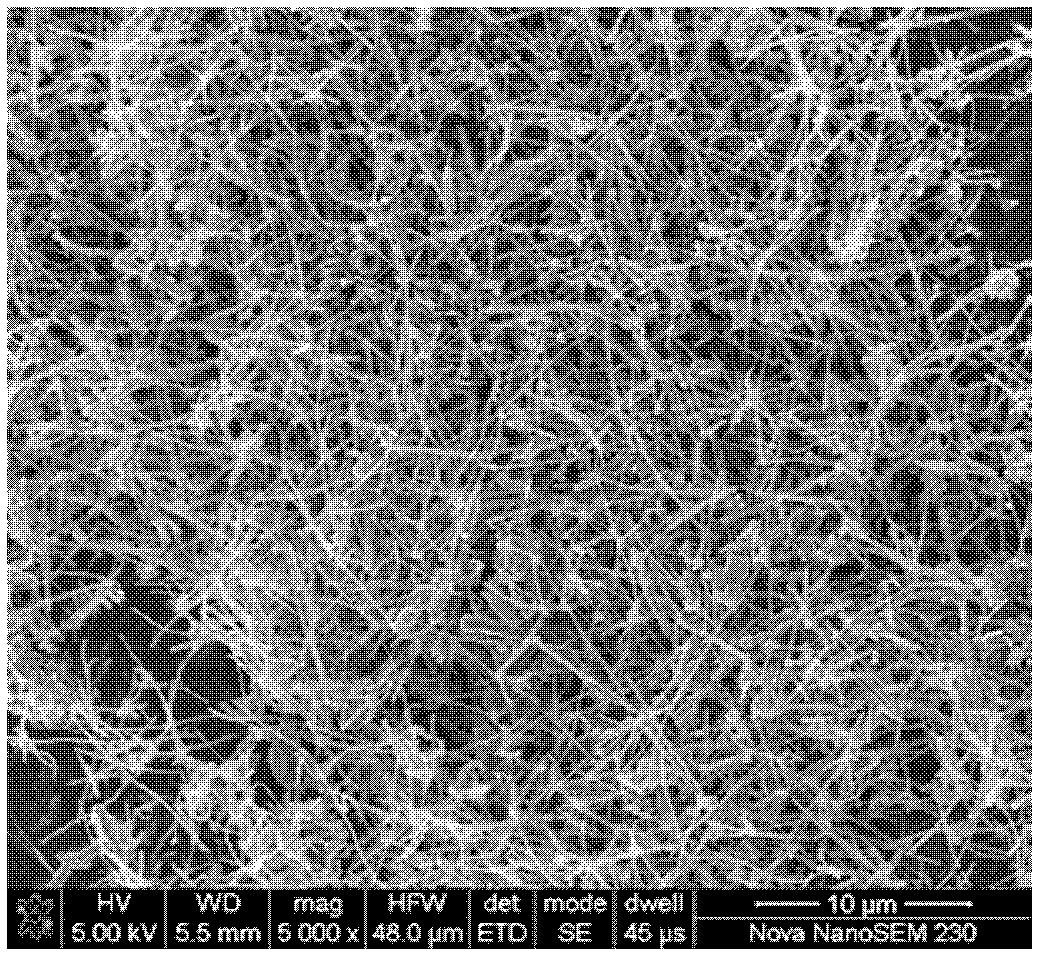

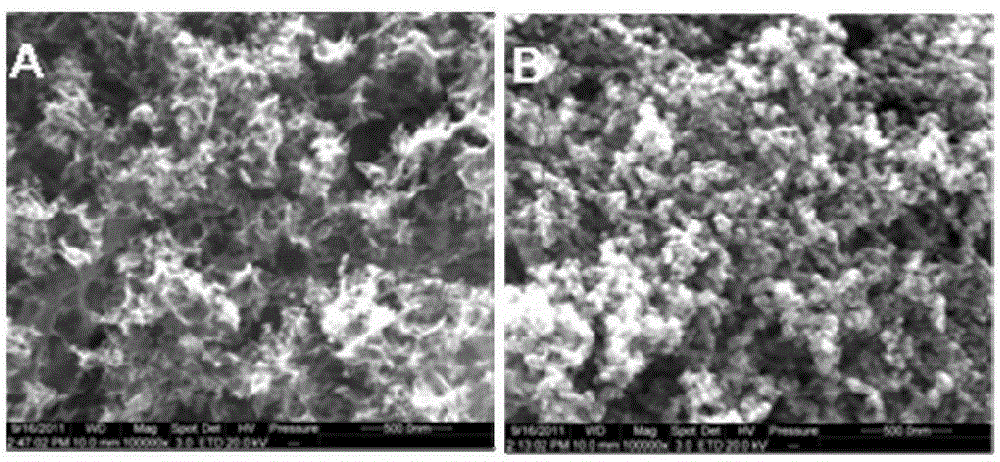

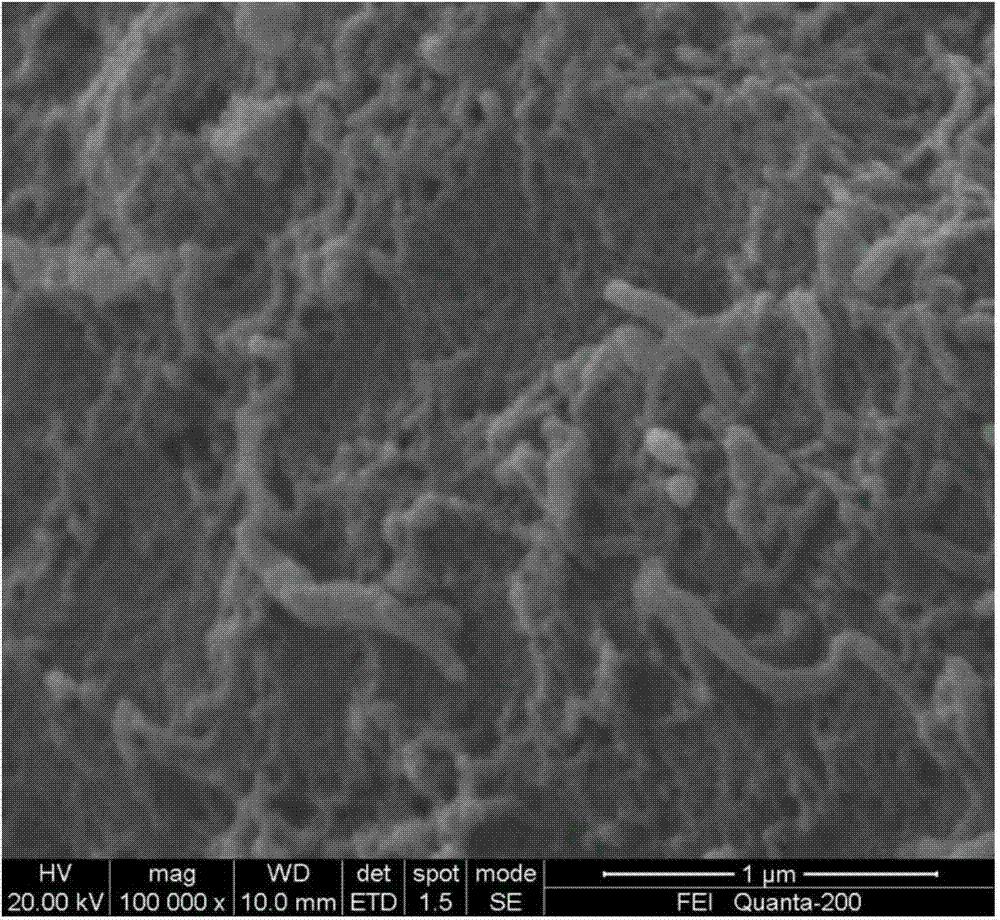

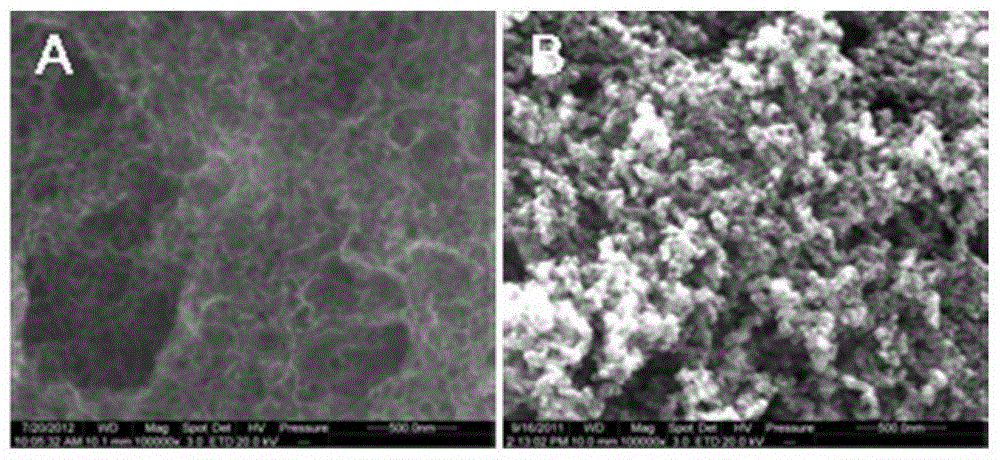

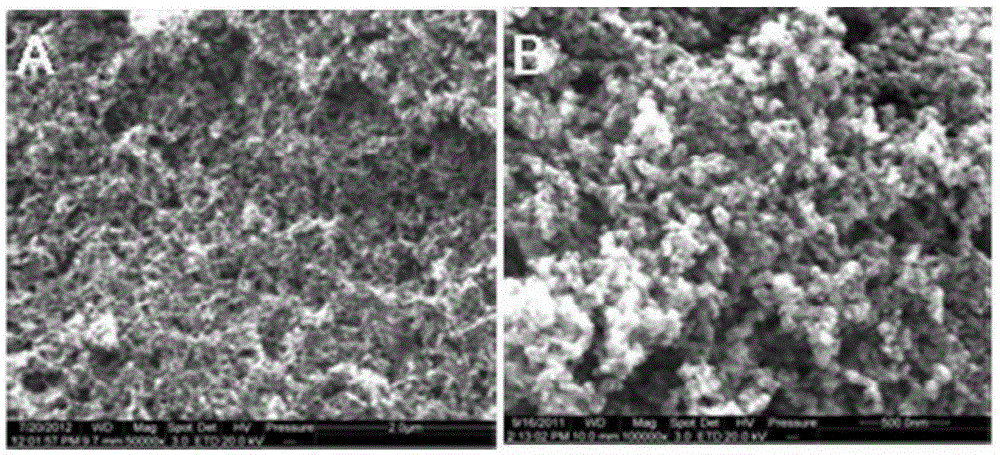

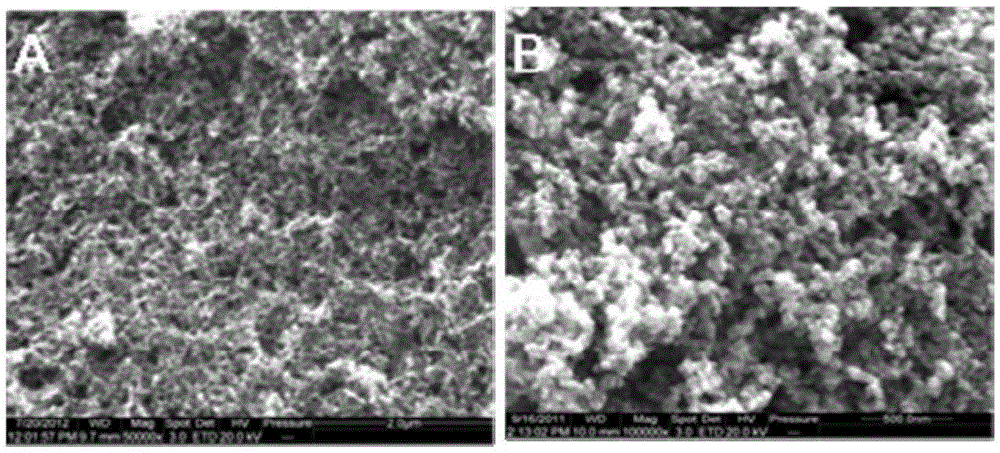

Micro-nano-structure anode material for Li-air battery and preparation method of micro-nano-structure anode material

The invention relates to a micro-nano-structure anode material for a Li-air battery and a preparation method of the micro-nano-structure anode material. The preparation method comprises the following steps of: preparation of hollow composite precursor fibers through electrostatic spinning by blending a metal nitride catalyst precursor with a high-carbon polymer in an organic solvent, preprocessing of the precursor fiber material, nitridation of complex fibers, and pore-forming and pore-expansion through activation. The preparation method is simple in technique and convenient to operate and is easy to realize the uniform distribution of nanoscale catalyst particles in hollow carbon fibers. A prepared anode material tube is hollow internally, a plurality of holes are formed on the wall of the tube, and metal nitride catalysts are uniformly distributed in the three-dimensional holes of the wall of the tube, so that high specific surface area provides a sufficient place for the reaction of the battery, and the hollow pore passage in the tube can ensure an oxygen diffusion channel to be smooth and has good ion transport capacity and electrical conductivity. According to the invention, the charge-discharge capacity of the Li-air battery can be improved effectively, the power multiplying performance and the power density of the Li-air battery can be improved, the internal resistance of the battery can be reduced, and the charge-discharge polarization can be lessened through the uniform distribution of the nanoscale metal nitride, therefore, the micro-nano-structure anode material has good industrialization prospect.

Owner:CENT SOUTH UNIV

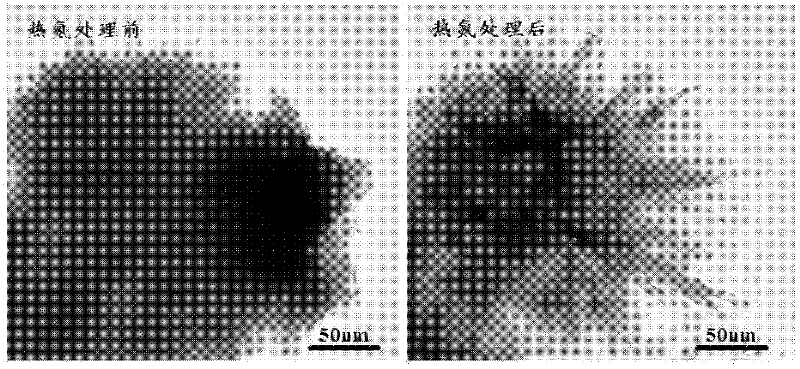

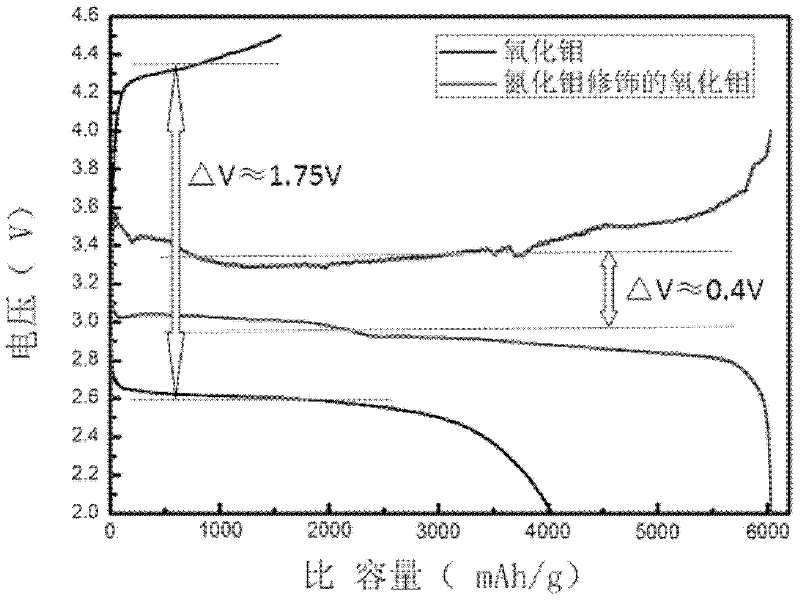

Composite electrocatalyst material used for Li-air batteries and preparation method thereof

InactiveCN102694185AImprove stabilityImprove conductivityPhysical/chemical process catalystsCell electrodesArgon atmosphereLithium–air battery

A composite electrocatalyst material used for Li-air batteries and a preparation method thereof. The transition metal oxide composite electrocatalyst modified by surface conductive transition metal nitride is obtained by conducting thermal nitrogen treatment, in an ammonia atmosphere or an ammonia and argon atmosphere, for transition metal oxide powder or transition metal oxide powder pretreated by nitrogen overlying, wherein the technology of the thermal nitrogen treatment is heating up the powder at a rate of 2-10 DEG C / min to reach the thermal nitrogen treatment temperature of 300-800 DEG C, preserving heat for 10min to 2h and then cooling in furnace. By controlling the content and flow rate of ammonia and the temperature and time of sintering, the thickness of the surface transition metal nitride can be controlled selectively. The method of the invention is simple in technology, convenient for operation, low in cost and strong in controllability. In addition, the obtained composite electrical catalyst has good conductivity and stability and can reduce the charging and discharging polarization of Li-air batteries effectively. The catalyst decreases the inner resistance of batteries and has good discharge capacity. The industrialization prospect of the catalyst is good.

Owner:CENT SOUTH UNIV

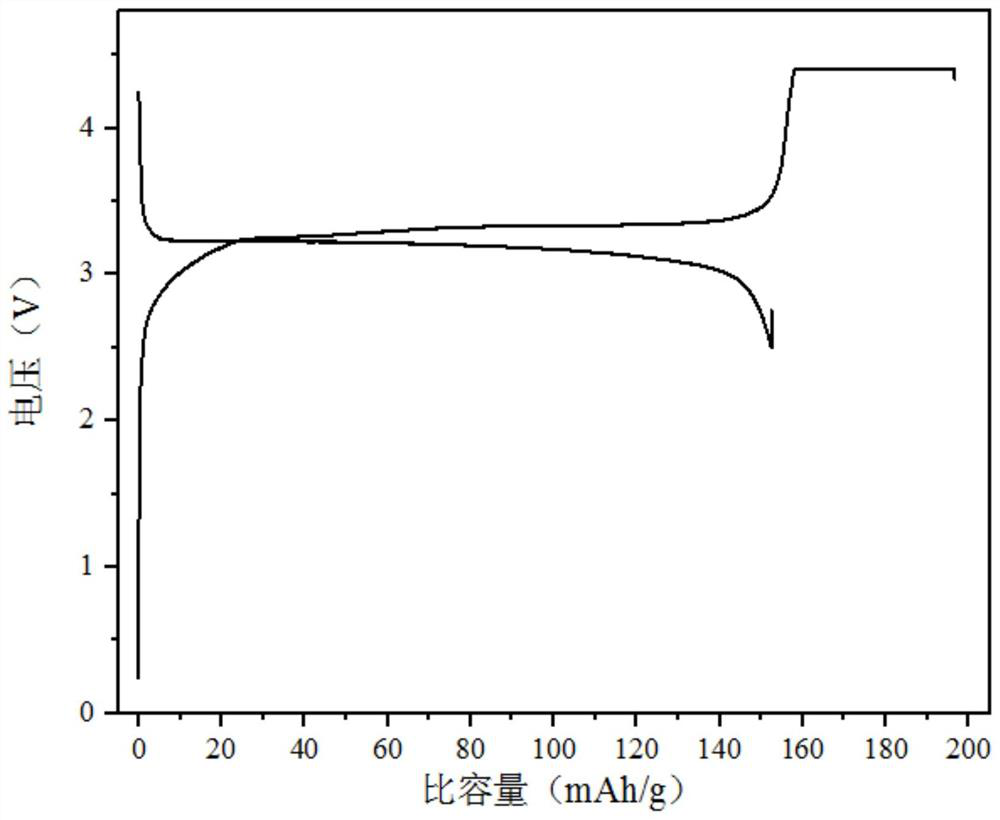

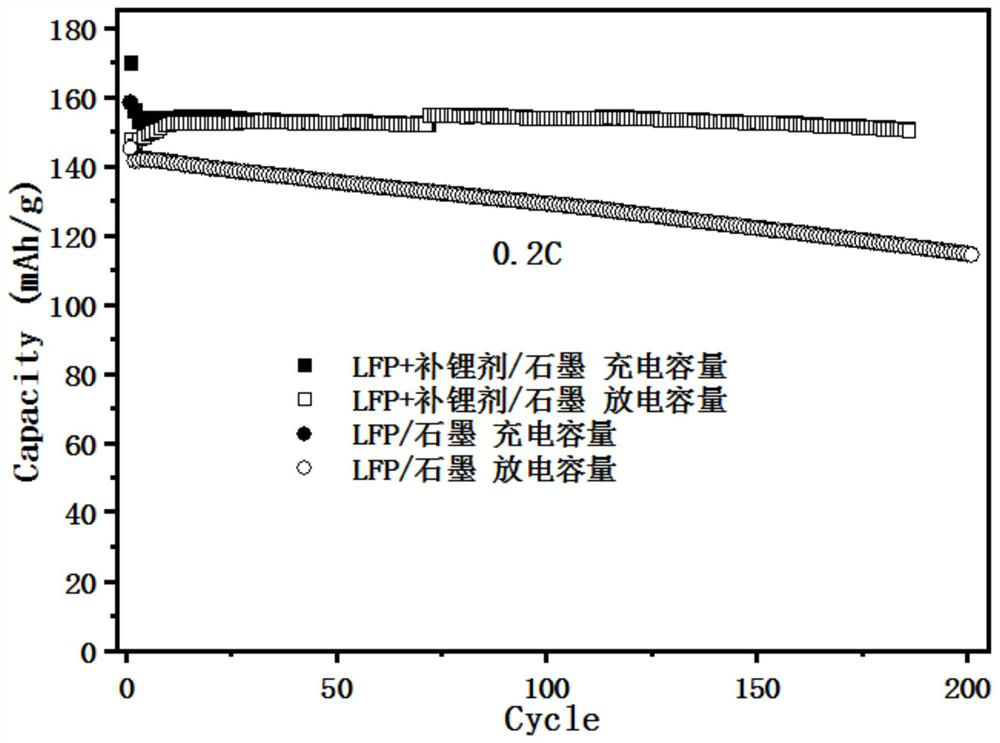

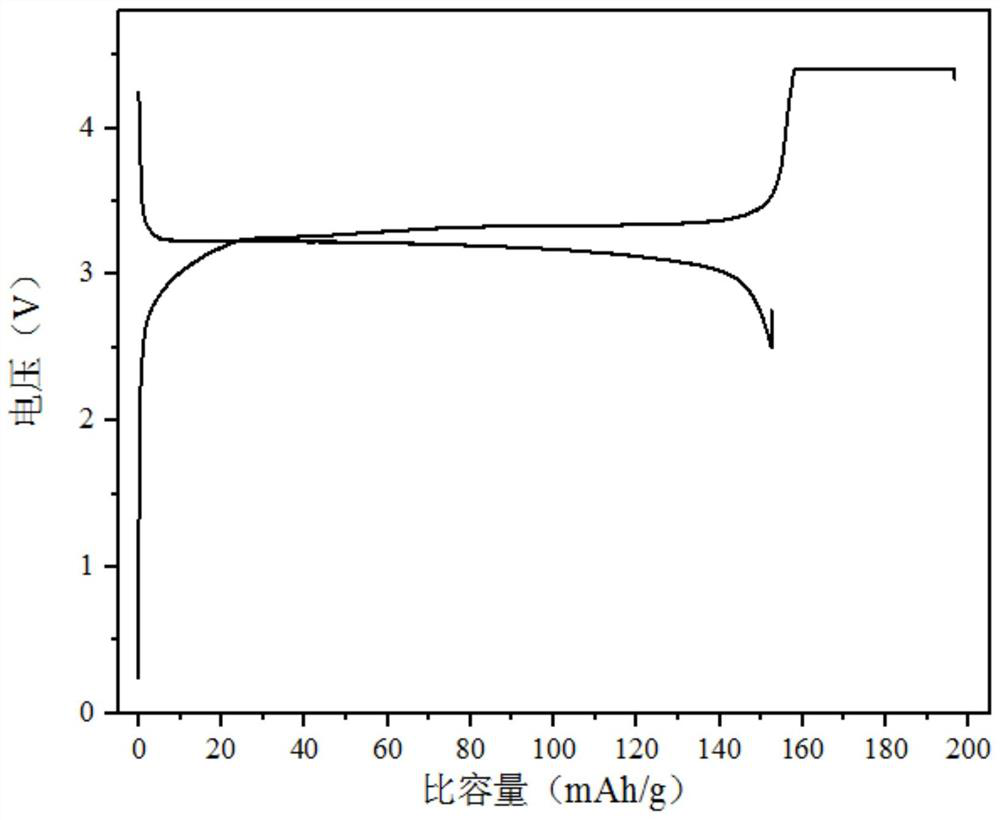

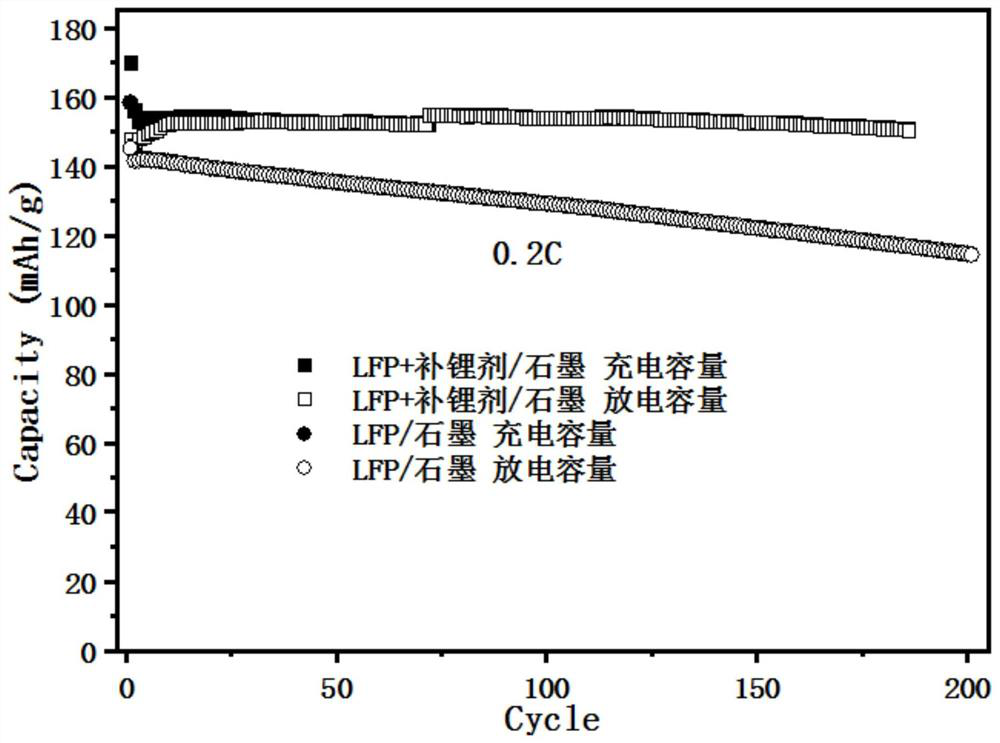

Lithium supplementing material and preparation method and application thereof

PendingCN112002894AReasonable formulaLower potentialCell electrodesSecondary cellsElectrolytic agentPtru catalyst

The invention discloses a lithium supplementing material for a lithium secondary battery as well as a preparation method and application thereof. The lithium supplementing material comprises a lithium-containing compound and an inorganic nonmetal reducing agent. According to the lithium supplementing material provided by the invention, inorganic sulfide is used as a reducing agent; meanwhile, metal and nonmetal catalysts are added; the potential of the lithium supplementing agent for exerting the capacity can be effectively reduced, and no gas is generated in the process of releasing lithium ions; the lithium supplementing material has good compatibility with the current commercial positive electrode and negative electrode, can be suitable for various battery systems, does not need to adjust and redesign an electrolyte and a battery manufacturing process, and is very suitable for the current secondary lithium ion battery. The preparation method of the lithium supplementing material provided by the invention is simple in process step, compatible with the existing lithium ion energy storage device preparation process, low in cost and suitable for mass production.

Owner:SONGSHAN LAKE MATERIALS LAB +1

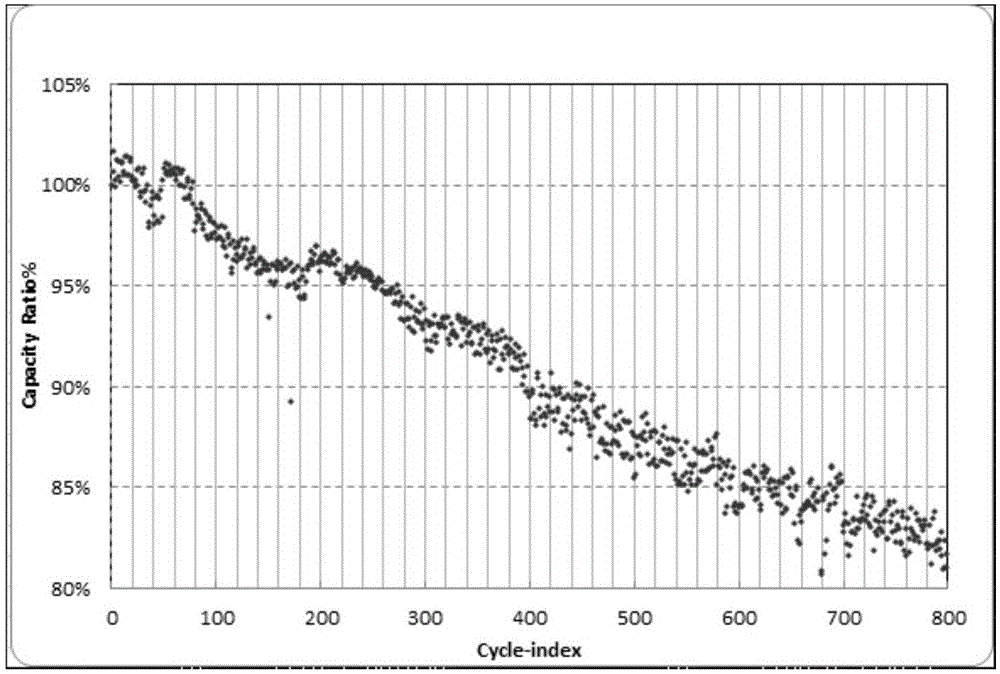

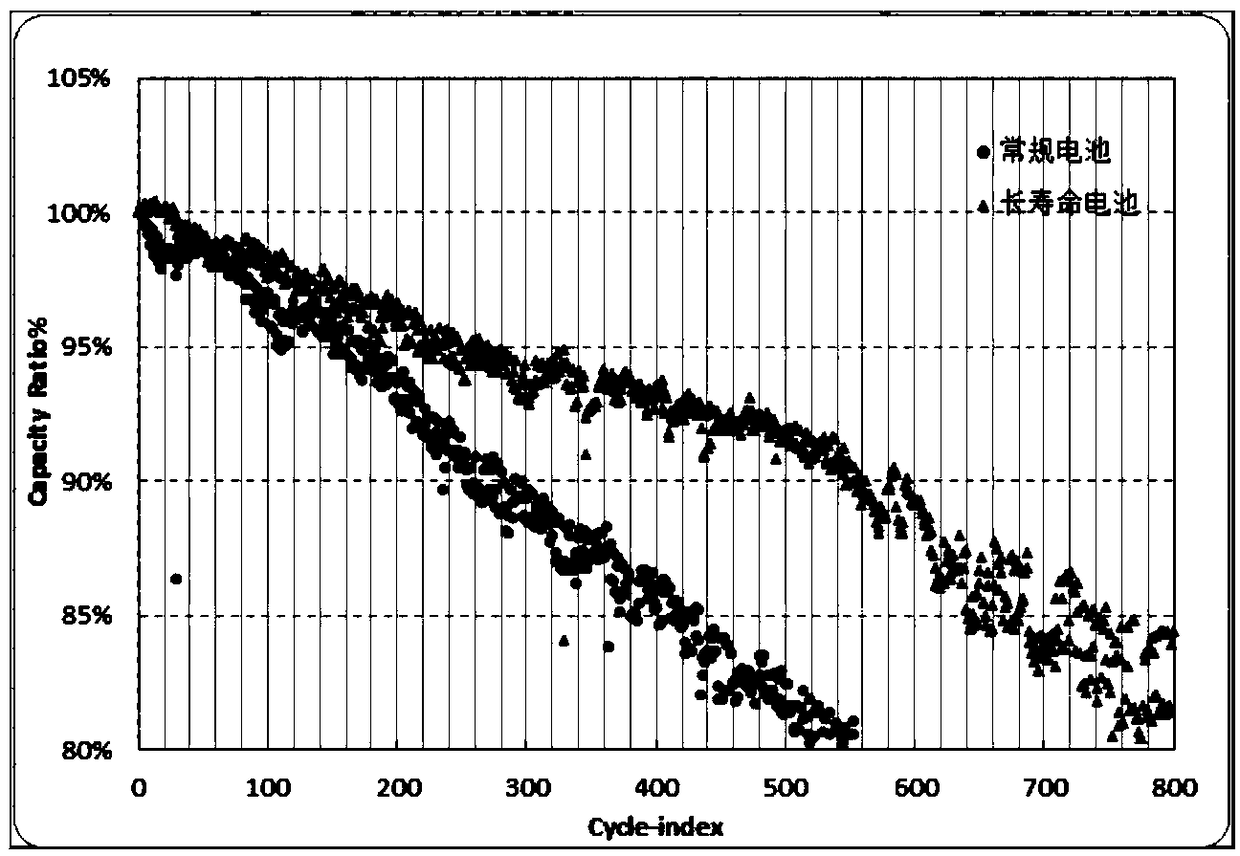

High-voltage and high-volumetric-energy-density long-life lithium ion battery and preparation method thereof

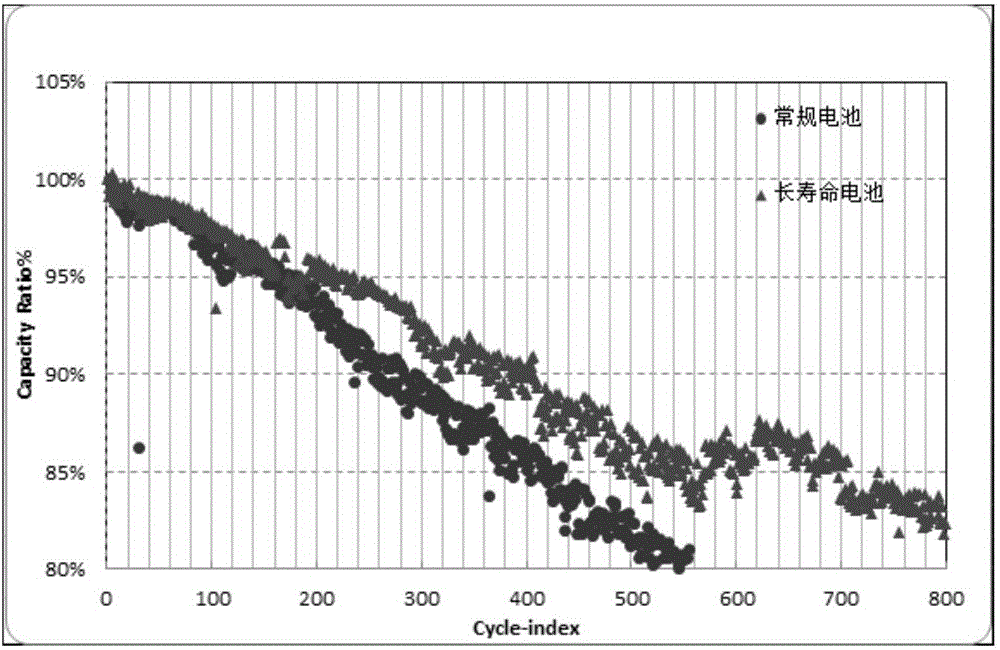

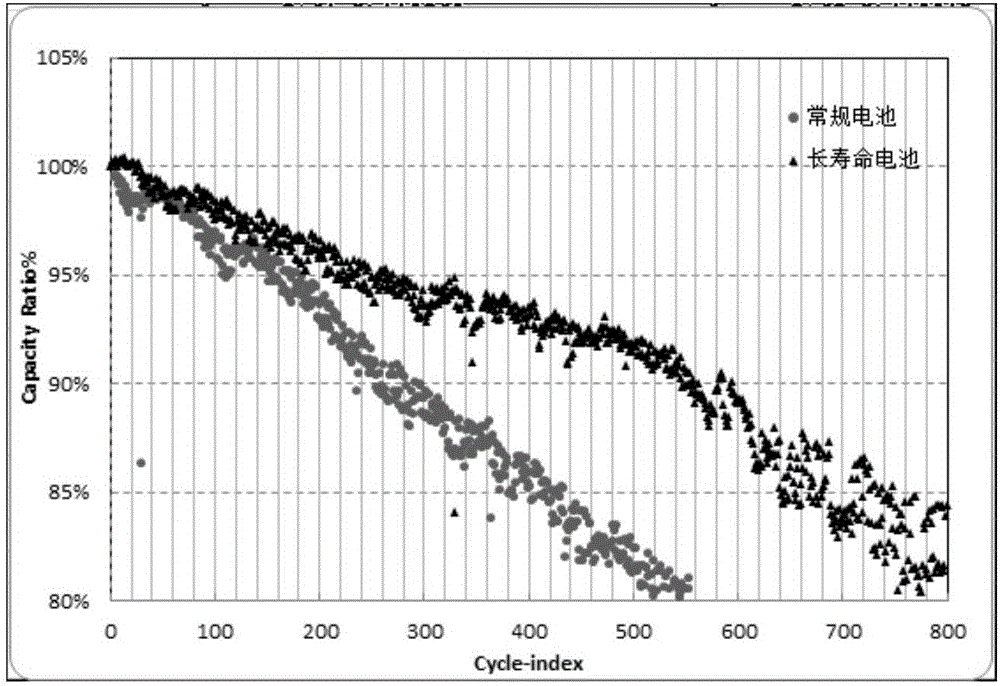

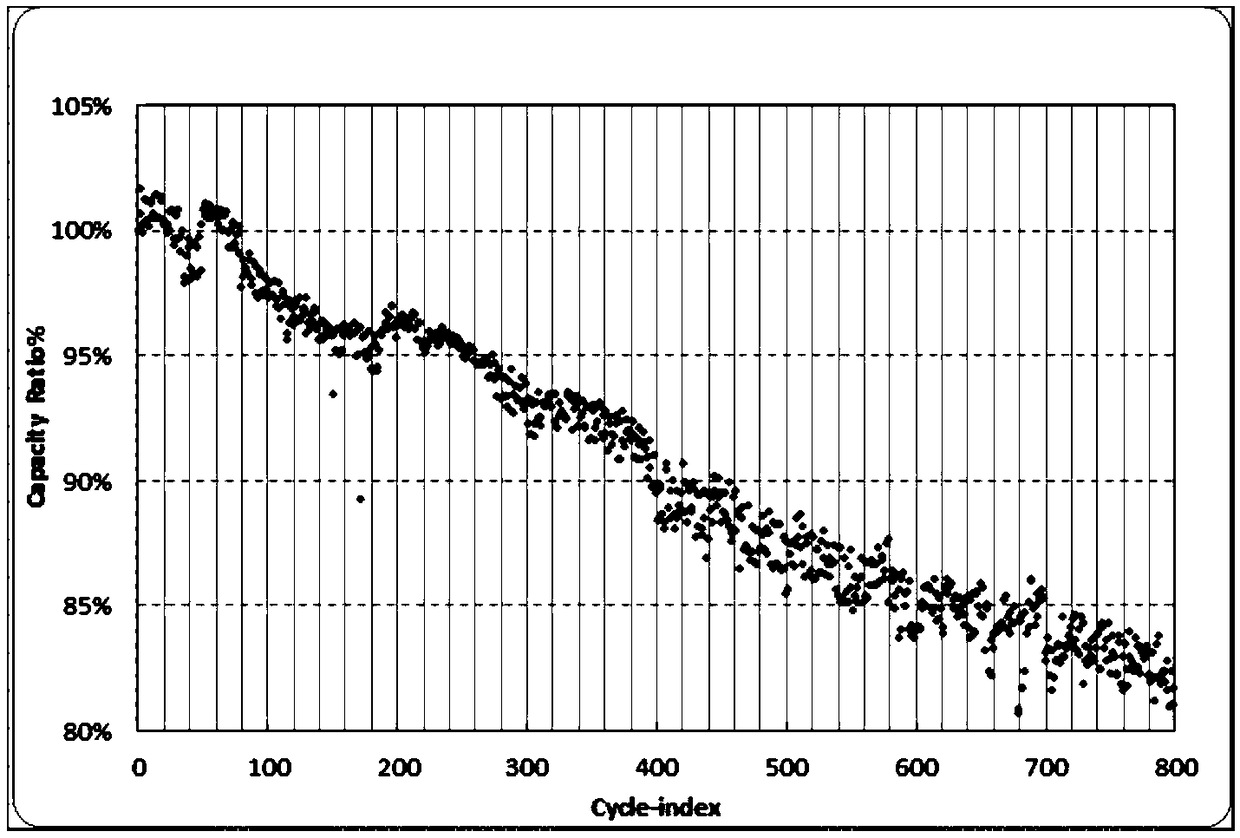

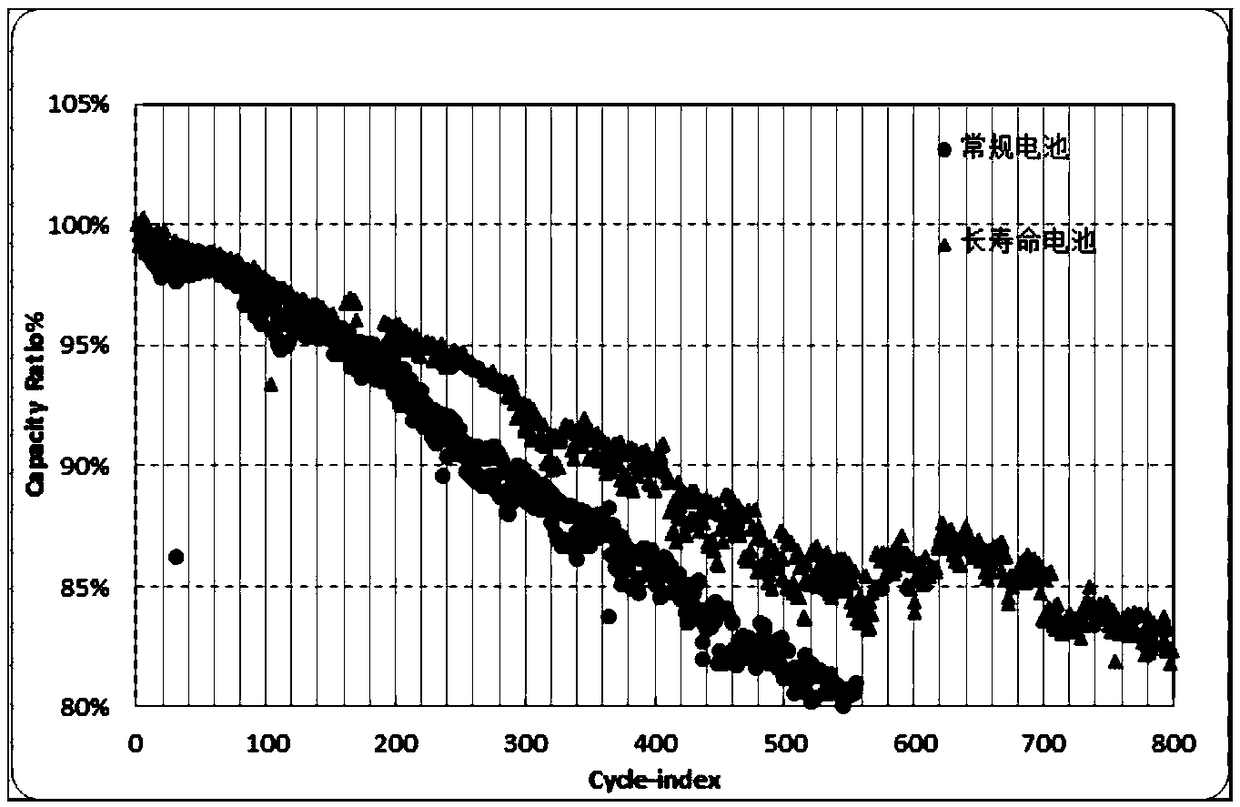

ActiveCN106252569AImprove conductivityEasy transferCell seperators/membranes/diaphragms/spacersFinal product manufacturePolyolefinFilm base

The invention provides a high-voltage and high-volumetric-energy-density long-life lithium ion battery and a preparation method thereof. The battery comprises a lithium ion battery outer shell aluminum-plastic packaging film, a positive electrode piece, a negative electrode piece, an isolation film, an electrolyte, and positive and negative electrode lugs, wherein the positive electrode piece uses carbon nanotubes (CNTs) as a conductive agent, and the isolation film comprises a polyolefin isolation film base and a mixed coating of Al2O3 and polyvinylidene fluoride (PVDF); the surface of the polyolefin isolation film base is coated with the mixture of Al2O3 and polyvinylidene fluoride (PVDF). The high-voltage and high-volumetric-energy-density long-life lithium ion battery provided by the invention not only has volumetric energy density of greater than or equal to 700Wh / L, but also has good electrochemical performance and safety performance, has outstanding cycle performance, and has a cycle life of 800 times and a capacity retention rate of 80% or above at normal temperature.

Owner:TIANJIN ENERGIES

Composite catalyst of air electrode of lithium-air cell

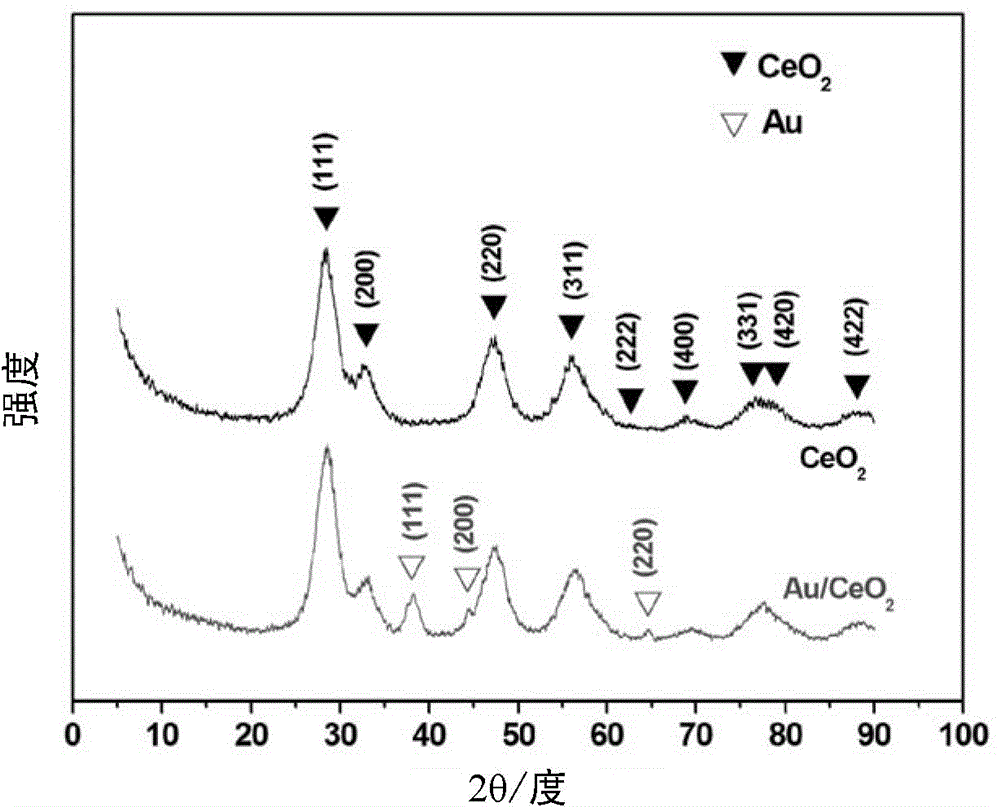

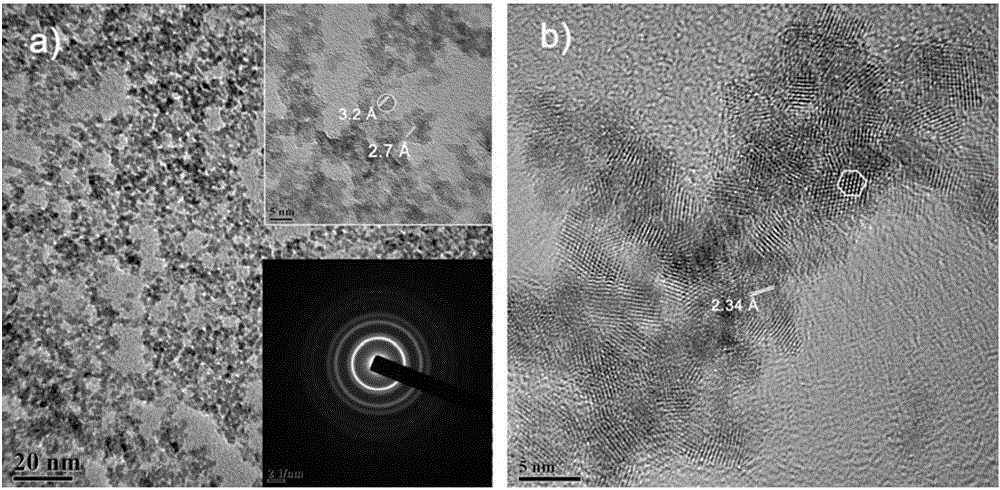

ActiveCN104466203AGood dispersionImprove stabilityFuel and primary cellsCell electrodesMetal catalystLithium–air battery

The invention relates to a composite catalyst of an air electrode of a lithium-air cell. The composite catalyst comprises a metal catalyst, and a support for performing synergic catalysis with the metal catalyst. The metal catalyst is uniformly distributed on the surface of the support via in-situ loading. The metal catalyst accounts for 0.01 wt%-99.9 wt% of the composite catalyst, preferably 0.1 wt%-60 wt%, and more preferably 0.5 wt%-5 wt%. By utilizing the metal catalyst and the support with synergic effect on the metal catalyst, the composite catalyst of the air electrode is formed, the dispersibility and the stability of the original metal catalyst are improved, and also the catalytic activity not owned or unreached by the single metal catalyst is induced to generate.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Nitrogen-doped porous carbon material used for anode of lithium-air cell

ActiveCN103855367AHigh discharge specific capacityHigh voltage platformFuel and secondary cellsCell electrodesLithiumPorous carbon

The invention relates to a nitrogen-doped porous carbon material used for anode of a lithium-air cell, which has a mutually communicated graded pore structure, N is uniformly doped in a C frame, wherein N accounts for 0.2-15% of carbon material, the graded pore comprises a mass transfer pore and a deposition pore, the pore volume of the deposition pore accounts for 40-95% of total pore volume, and the pore volume of the mass transfer pore accounts for 4-55% of total pore volume. The carbon material as the lithium-air cell material can greatly increase the space utilization rate of the carbon material during a charge and discharge process at maximum limit, so that lithium-air cell energy density and power density can be effectively increased. The nitrogen-doped porous carbon material used for anode of lithium-air cell has the advantages that the preparation technology is simple, the material source is wide, the pore structure of the graded aperture carbon material enables regulation and control, and the regulation and control modes are various, and the nitrogen doping mode is easy to realize.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Nitrogen-doped porous carbon material for lithium-air battery positive electrode

ActiveCN103855365AIncrease profitImprove space utilizationFuel and secondary cellsCell electrodesLithium–air batteryPower density

The present invention relates to a nitrogen-doped porous carbon material for a lithium-air battery positive electrode. The nitrogen-doped porous carbon material is characterized in that the nitrogen-doped porous carbon material has an interconnected graded pore structure, N is uniformly doped in the C skeleton, N accounts for 0.2-15% of the carbon material atomic ratio, the graded pores comprise mass transfer pores and deposition holes, the deposition holes account for 40-95% of the total pore volume, and the mass transfer pores account for 4-55% of the total pore volume. According to the present invention, with application of the carbon material as the lithium-air battery electrode material, the space utilization rate of the carbon material during the charge-discharge process can be increased at a maximum, and the energy density and the power density of the lithium-air battery can be effectively increased; and the preparation process is simple, the material source is wide, the pore structure of the graded pore carbon material can be regulated, the regulation manner is diverse, and the nitrogen doping manner is easily achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Electrolyte and lithium ion battery

ActiveCN112397786ALow costLower internal resistanceSecondary cellsOrganic electrolytesElectrolytic agentOrganic solvent

The invention provides an electrolyte and a lithium ion battery, and belongs to the technical field of batteries. The electrolyte comprises an organic solvent and a lithium salt dissolved in the organic solvent, and also comprises an auxiliary agent. The auxiliary agent is selected from one or more of S elementary substance, B elementary substance, P elementary substance and a reducing compound capable of releasing specific negative ions in the electrolyte, and the specific negative ions are selected from one or more of S negative ions, B negative ions and P negative ions. The lithium ion battery comprises the electrolyte. The specific type of auxiliary agent can effectively reduce the potential when a lithium-containing compound is decomposed; and by adding the auxiliary agent into the electrolyte, the battery is ensured to have better cycling stability, and meanwhile, the applicability in a battery production process is good.

Owner:SONGSHAN LAKE MATERIALS LAB +1

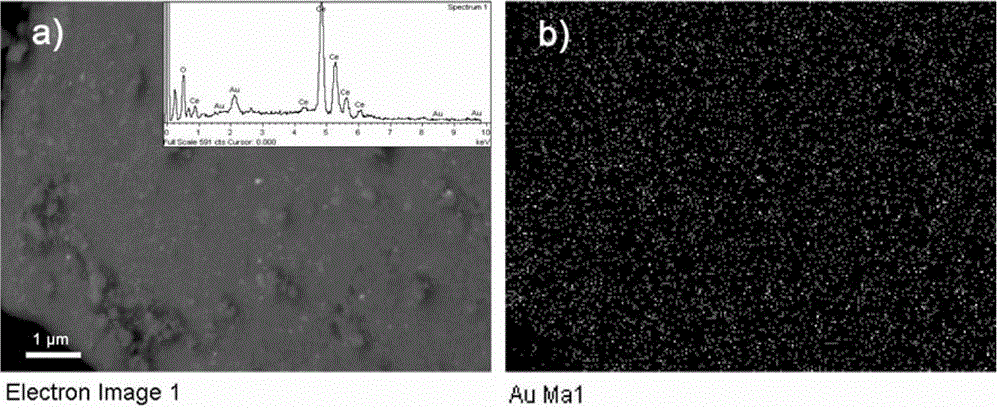

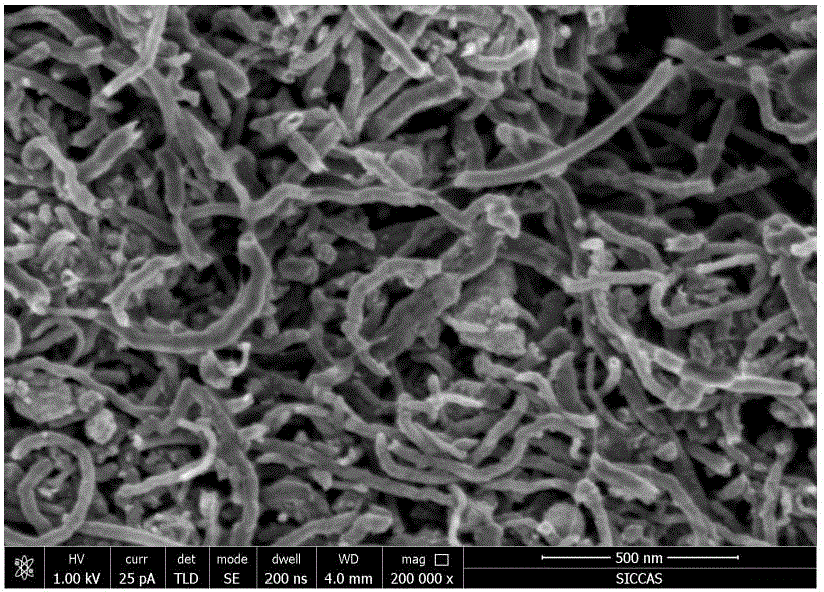

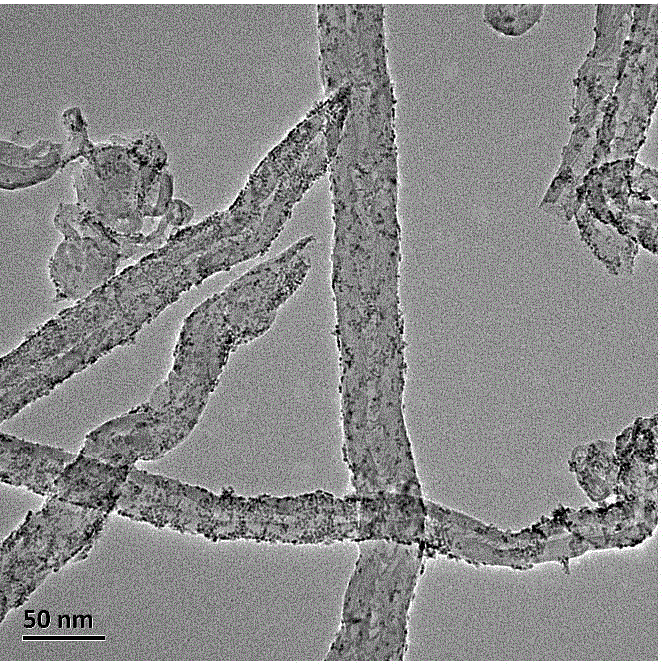

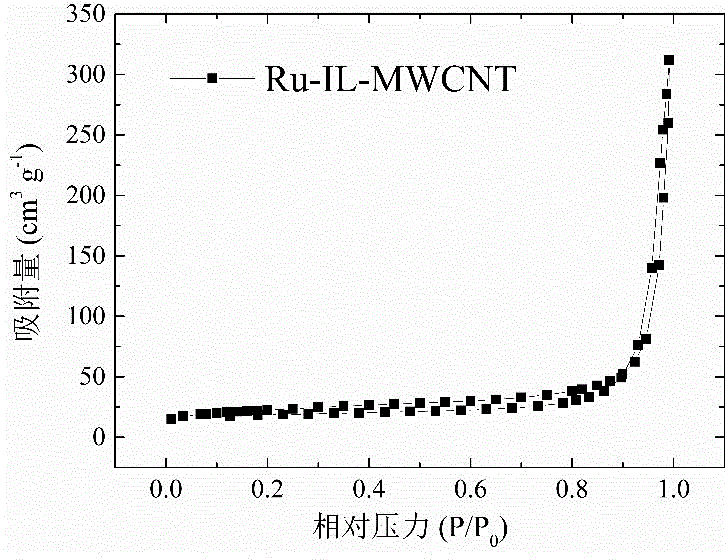

Carbon-based composite positive electrode material for lithium-air battery and preparation method of carbon-based composite positive electrode material

ActiveCN105810953AThe reaction operation is convenient and easySimple processCell electrodesLithium–air batteryPrecious metal

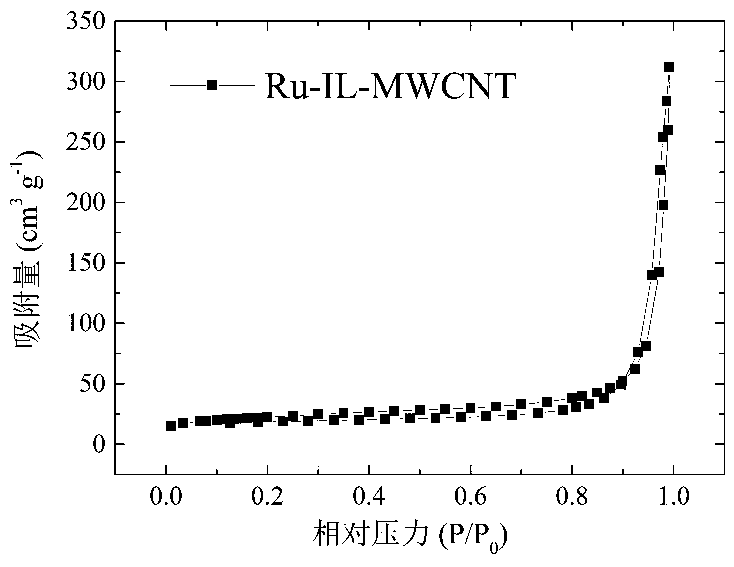

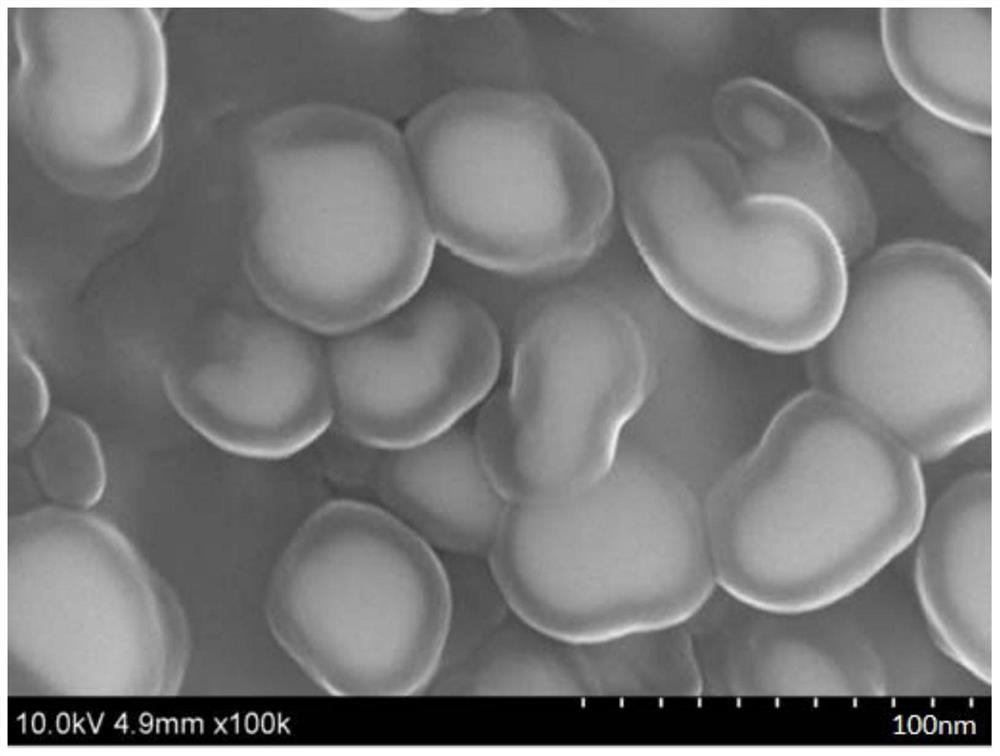

The invention relates to a carbon-based composite positive electrode material for a lithium-air battery and a preparation method of the carbon-based composite positive electrode material. The carbon-based composite positive electrode material comprises a carbon material, a protection layer and precious metal particles, wherein the protection layer wraps the surface of the carbon material and is composed of an ionic liquid, and the precious metal particles are dispersed in the ionic liquid in a nanoparticle form so as to modify the surface of the carbon material.

Owner:江苏先进无机材料研究院

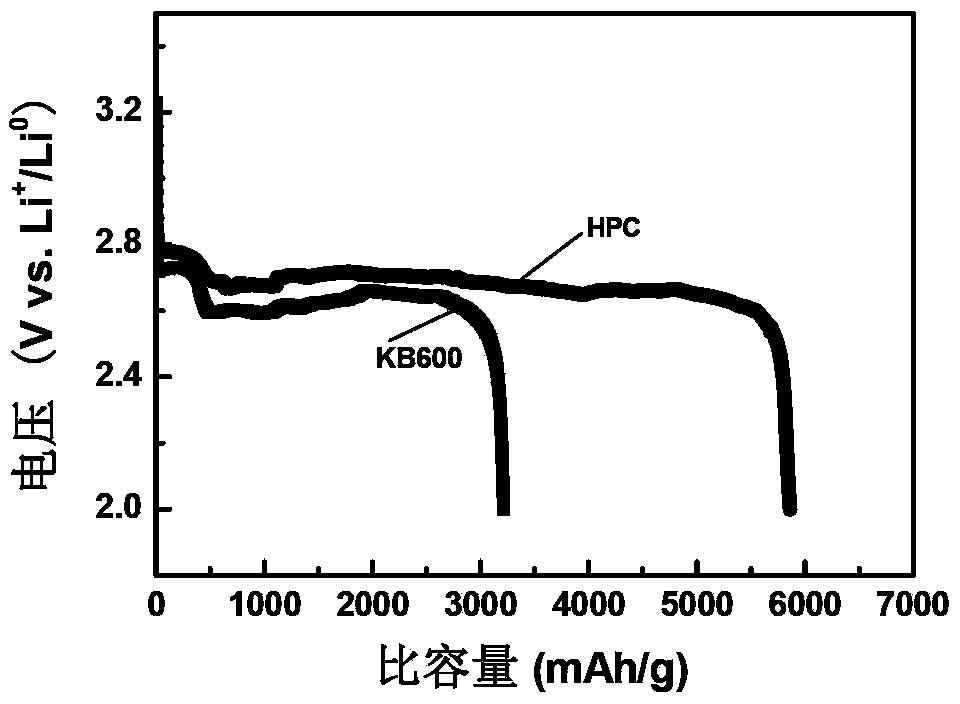

Porous carbon material for lithium-air battery positive electrode

ActiveCN103855394AShorten the diffusion distanceImprove space utilizationFuel and secondary cellsCell electrodesPorous carbonLithium–air battery

The present invention relates to an application of a graded pore structure porous carbon material in a lithium-air battery. The porous carbon material is characterized in that the porous carbon material has interconnected graded pore structure distribution, wherein the interconnected graded pore structure distribution comprises a mesopore structure for discharge product deposition and a macropore structure for oxygen and electrolyte transmission. According to the present invention, with application of the carbon material as the lithium-air battery electrode material, the space utilization rate of the carbon material during the charge-discharge process can be increased at a maximum, and the discharge specific capacity, the voltage platform and the rate discharge capability of the battery can be effectively increased so as to increase the energy density and the power density of the lithium-air battery; and the preparation process is simple, the material source is wide, the pore structure of the graded pore carbon material can be regulated, the regulation manner is diverse, and the metal / metal oxide doping can be concurrently and easily achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

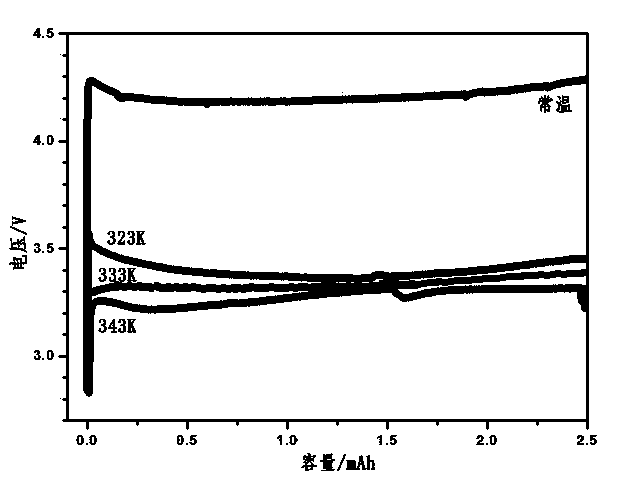

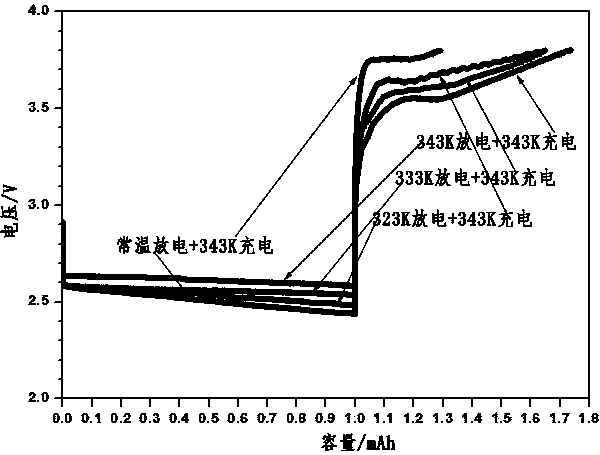

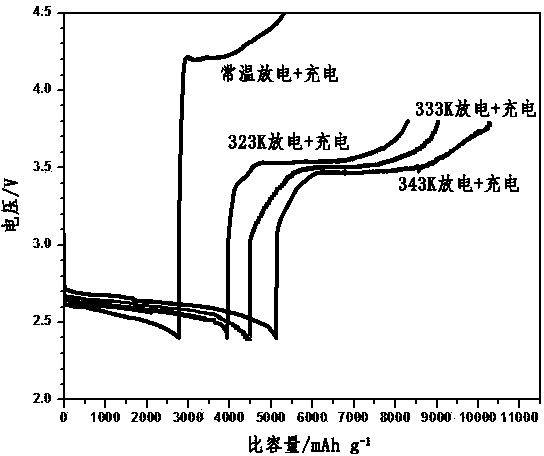

Method for reducing charge and discharge polarization of lithium air battery with nonaqueous electrolytic solution

InactiveCN104362405AReduce charge and discharge polarizationEnhanced bulk charge transport capabilityFuel and secondary cellsSecondary cells charging/dischargingElectrolytic agentLithium–air battery

The invention discloses a method for reducing the charge and discharge polarization of a lithium air battery with a nonaqueous electrolytic solution. According to the method, the purpose of reducing the charge and discharge polarization of the lithium air battery with the nonaqueous electrolytic solution can be achieved on the basis of neither increasing the battery cost nor reducing the energy density of the battery; the method is simple and easy to realize.

Owner:四川省有色冶金研究院有限公司

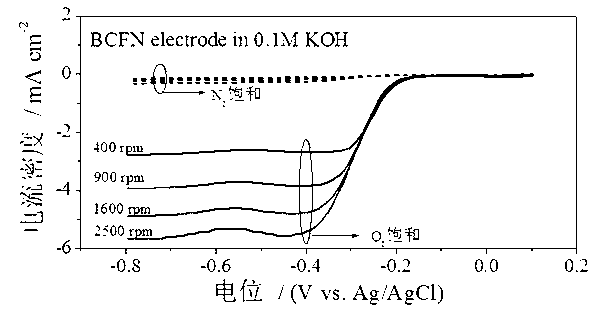

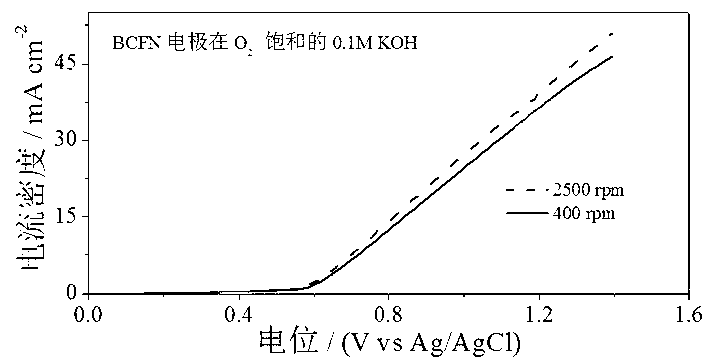

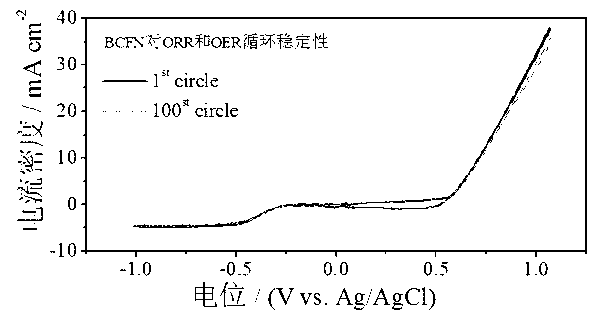

Lithium-air battery cathode bifunctional catalyst and application thereof

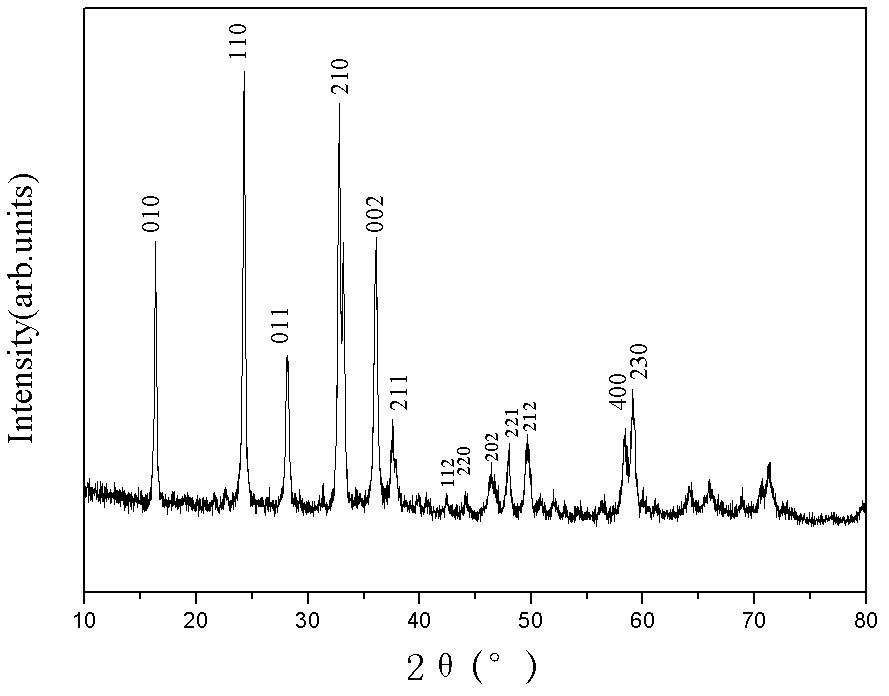

InactiveCN103268947ADual functionReduce charge and discharge polarizationCell electrodesElectrical batteryHigh energy

The invention discloses a lithium-air battery cathode bifunctional catalyst and application thereof. The catalyst is a compound with a perovskite crystal structure and particularly is Ba0.9Co0.7Fe0.2Nb0.1O3, La0.6Sr0.4Co0.2Fe0.8O3, Pr0.4Sr0.6Co0.2Fe0.7Nb0.1O3 or Ba0.5Sr0.5Co0.8Fe0.2O3. The lithium-air battery cathode bifunctional catalyst can be used for obviously reducing the charge / discharge polarization of a battery and achieving high charge / discharge capacity, has excellent charge / discharge multiplying power and long cycle life, can be used for obviously reducing the production cost, and has excellent catalytic efficiency. A lithium-air battery containing the catalyst has the advantage of high energy density and is applicable to the fields of various mobile electronic equipment and electric batteries.

Owner:SUZHOU UNIV

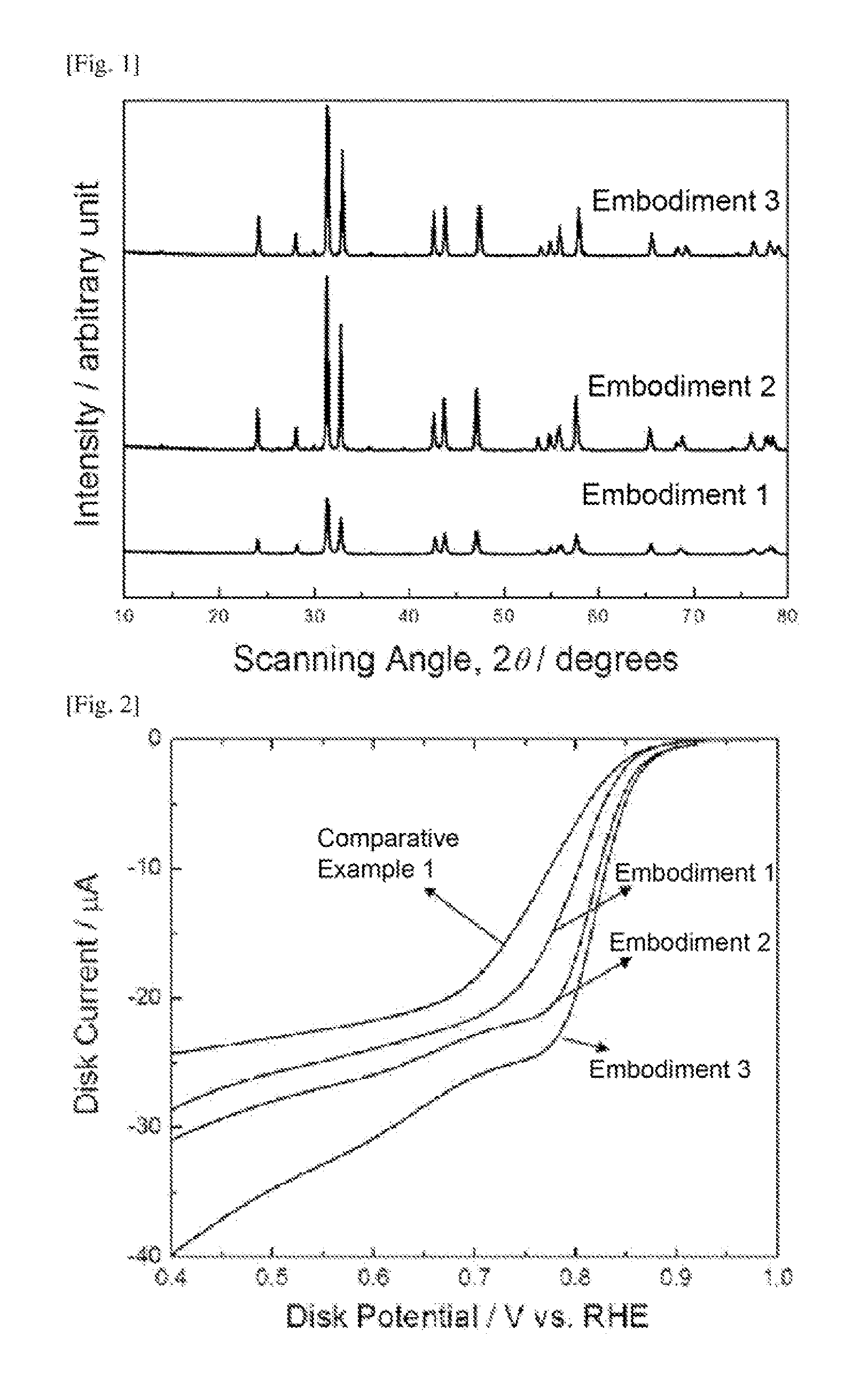

Cathode catalyst for metal-air battery, method for manufacturing same, and metal-air battery comprising same

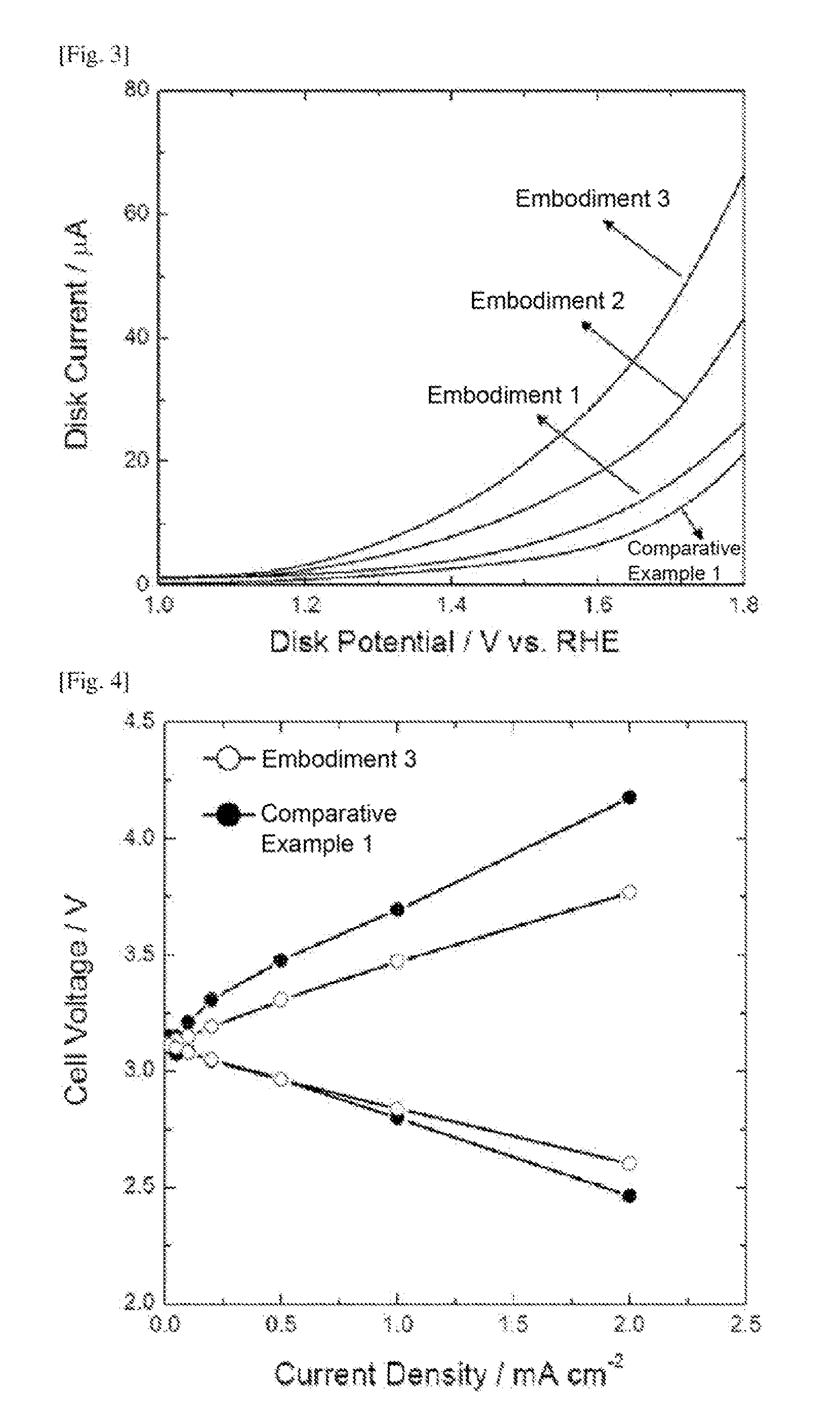

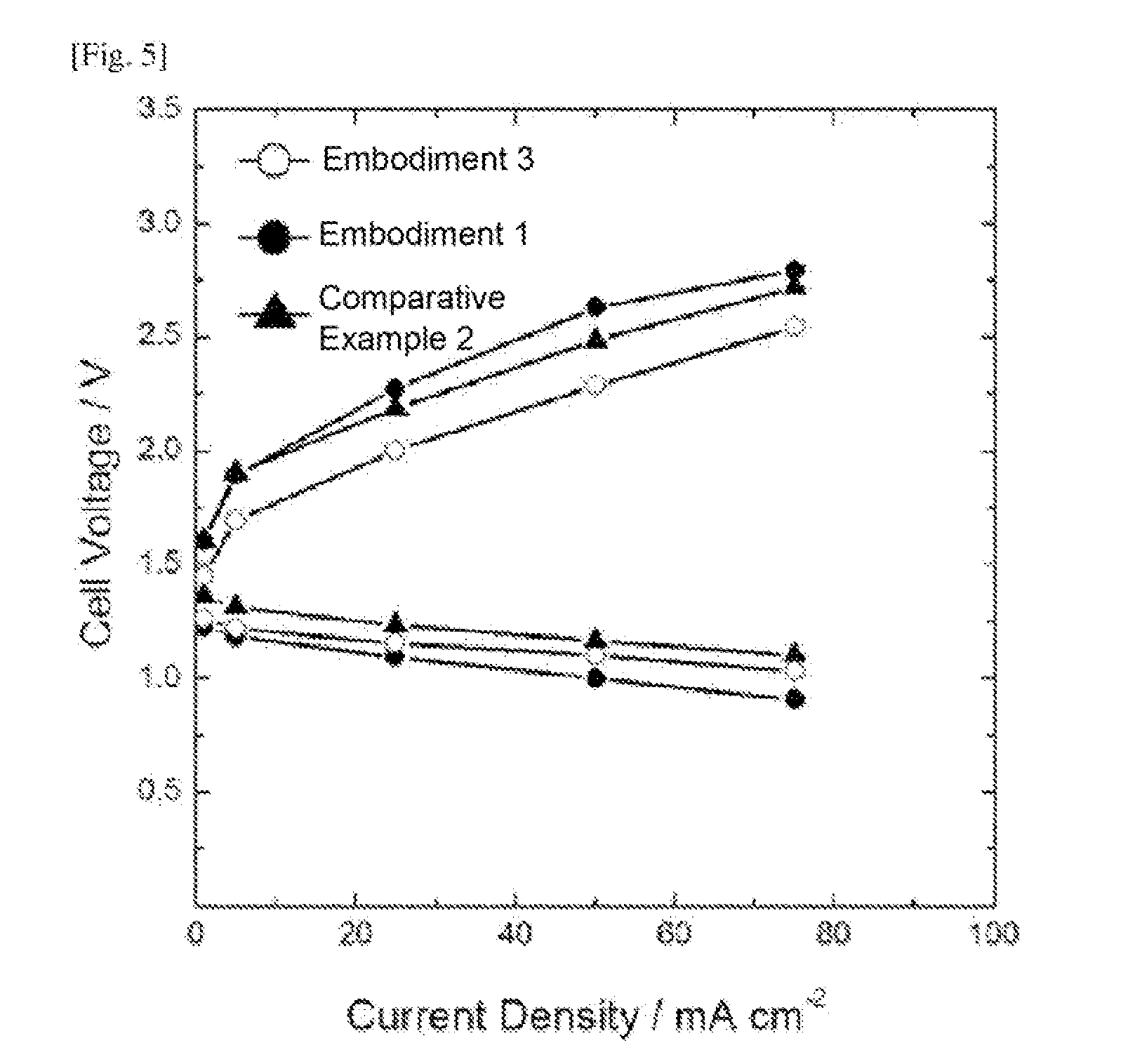

InactiveUS20160204445A1High charge and discharge capacityReduce charge and discharge polarizationFuel and primary cellsFuel and secondary cellsChemistryElectrical battery

The present invention relates to a cathode catalyst for a metal-air battery, a method for manufacturing the same, and a metal-air battery comprising the same. More specifically, the present invention relates to a cathode catalyst for a metal-air battery, a method for manufacturing the same, and a metal-air battery comprising the same having an improved storage capacity for charging / discharging and an increased charge-discharge cycle lifetime. The cathode catalyst is characterized by having a layered perovskite structure, and including lanthanum and nickel oxides. The cathode catalyst including the layered perovskite is used for manufacturing a cathode for a metal-air battery, and a metal-air battery is provided using the same. As a result, the charge-discharge polarisation of the metal-air battery is decreased, the storage capacity is increased, and the charge-discharge cycle lifetime can be improved.

Owner:KOREA INST OF ENERGY RES

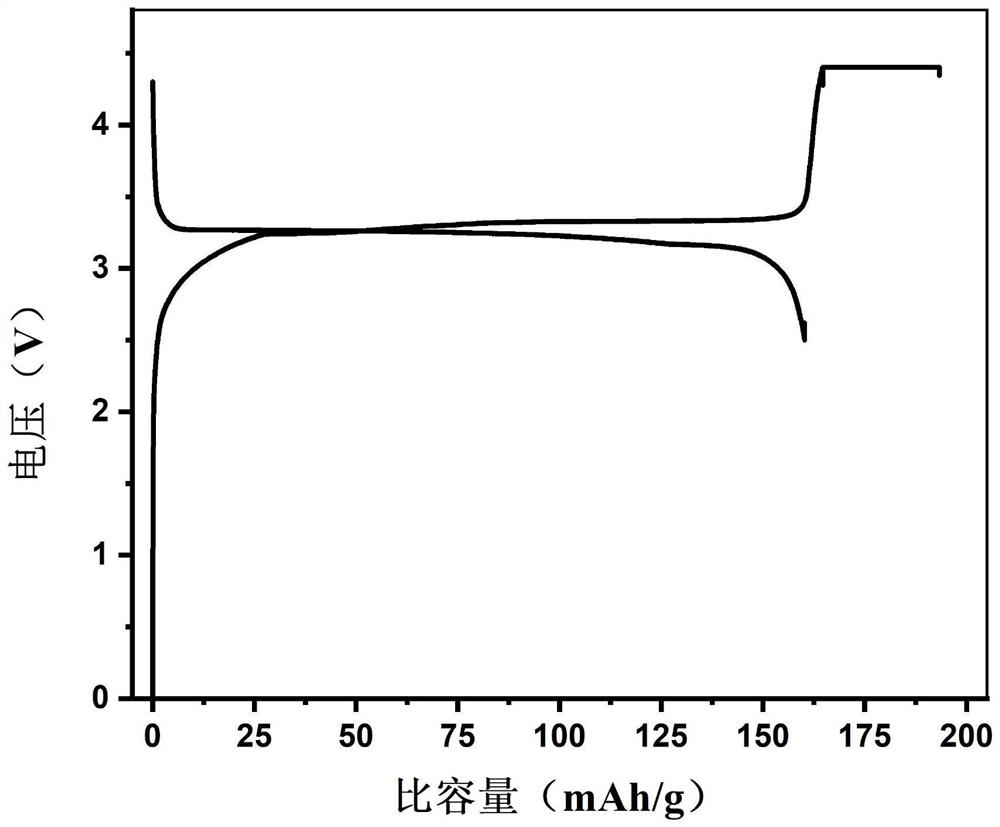

Preparation method of lithium manganous silicate cathode material with mesoporous structure

The invention discloses a preparation method of a lithium manganous silicate cathode material with a mesoporous structure, belonging to the field of lithium ion batteries. The method comprises two processes of liquid-phase reaction and high-temperature solid-phase sintering, wherein the process of liquid-phase reaction comprises the following steps of: performing ultrasonic dispersion of the mixture of a silicon-based molecular sieve or silicon dioxide and a carbon-containing template agent into an aqueous solution of lithium salt to obtain a dispersion; dissolving manganese salt in an organic solvent to obtain a solution 1; and mixing and stirring the dispersion and the solution 1, and performing hydrothermal or oil-bath reaction, washing, filtration and vacuum drying to obtain a precipitate 2; and the process of high-temperature solid-phase sintering comprises the following steps of: performing mechanical ball milling of the precipitate 2 for 2-5 hours, and calcining in a tubular furnace in an atmosphere of argon to obtain a final product, namely the lithium manganous silicate cathode material with a mesoporous structure. Through the lithium manganous silicate cathode material with a mesoporous structure, the specific surface area of the product is larger than that of the lithium manganous silicate prepared by a conventional method.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Nitrogen-doped porous carbon material for positive electrode of lithium-air battery

ActiveCN103855366BHigh discharge specific capacityHigh voltage platformFuel and secondary cellsCell electrodesPorous carbonCharge discharge

The present invention relates to a nitrogen-doped porous carbon material for a lithium-air battery positive electrode, wherein the nitrogen-doped porous carbon material has an interconnected graded pore structure, N is uniformly doped in the C skeleton, N accounts for 0.2-15% of the carbon material atomic ratio, the graded pores comprise mass transfer pores and deposition holes, the deposition holes account for 40-95% of the total pore volume, and the mass transfer pores account for 4-55% of the total pore volume. According to the present invention, with application of the carbon material as the lithium-air battery electrode material, the space utilization rate of the carbon material during the charge-discharge process can be increased at a maximum, and the energy density and the power density of the lithium-air battery can be effectively increased; and the preparation process is simple, the material source is wide, the pore structure of the graded pore carbon material can be regulated, the regulation manner is diverse, and the nitrogen doping manner is easily achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

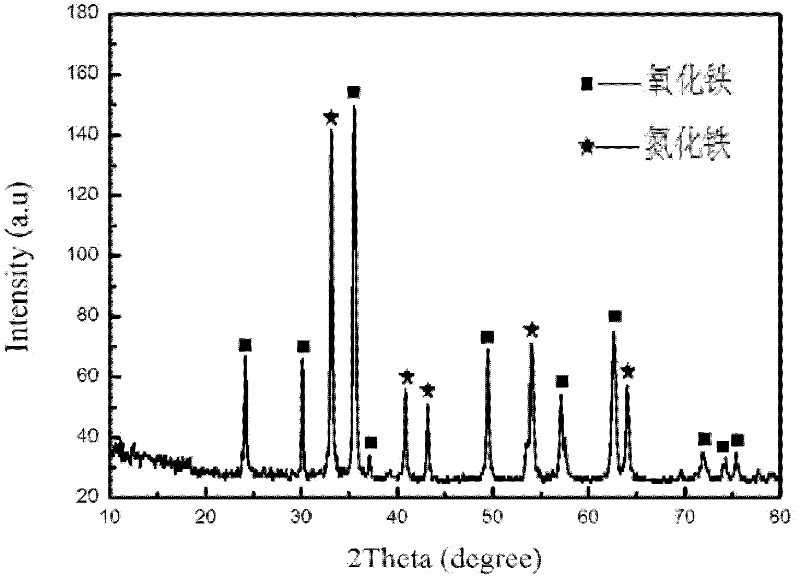

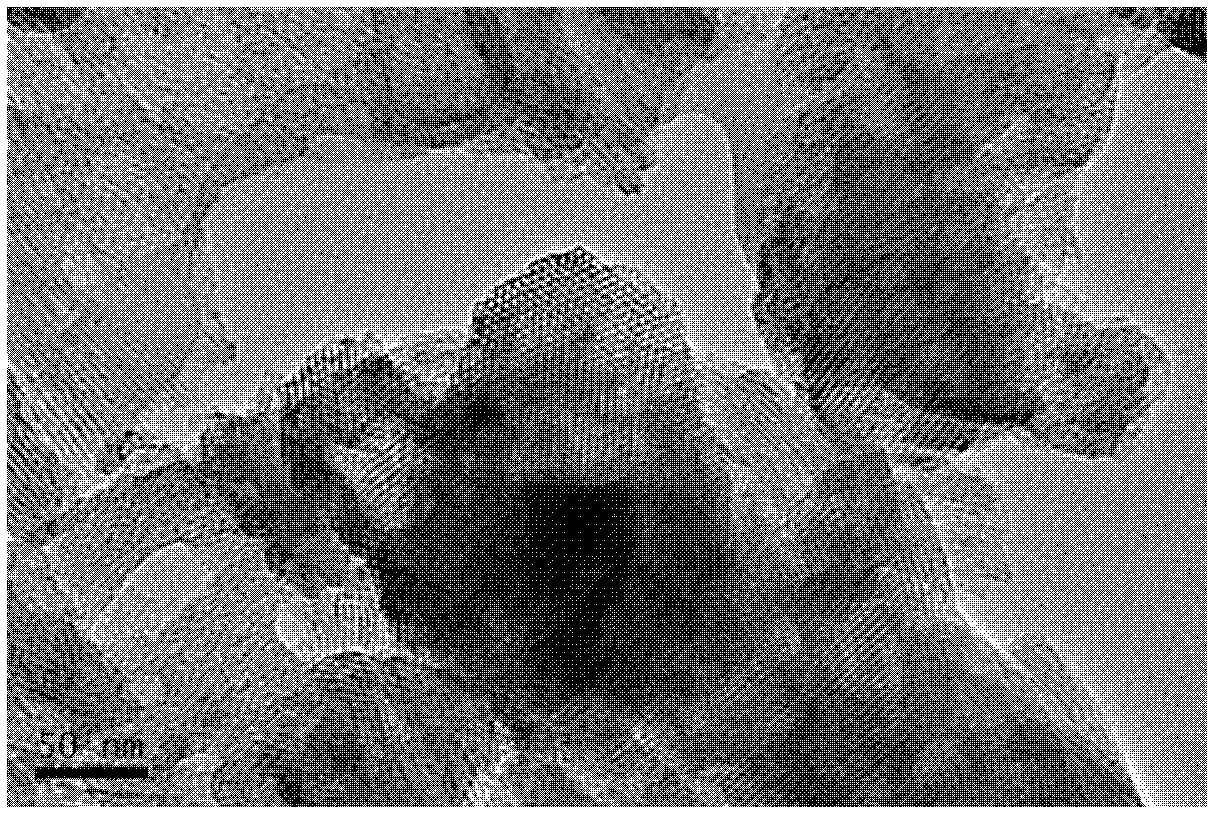

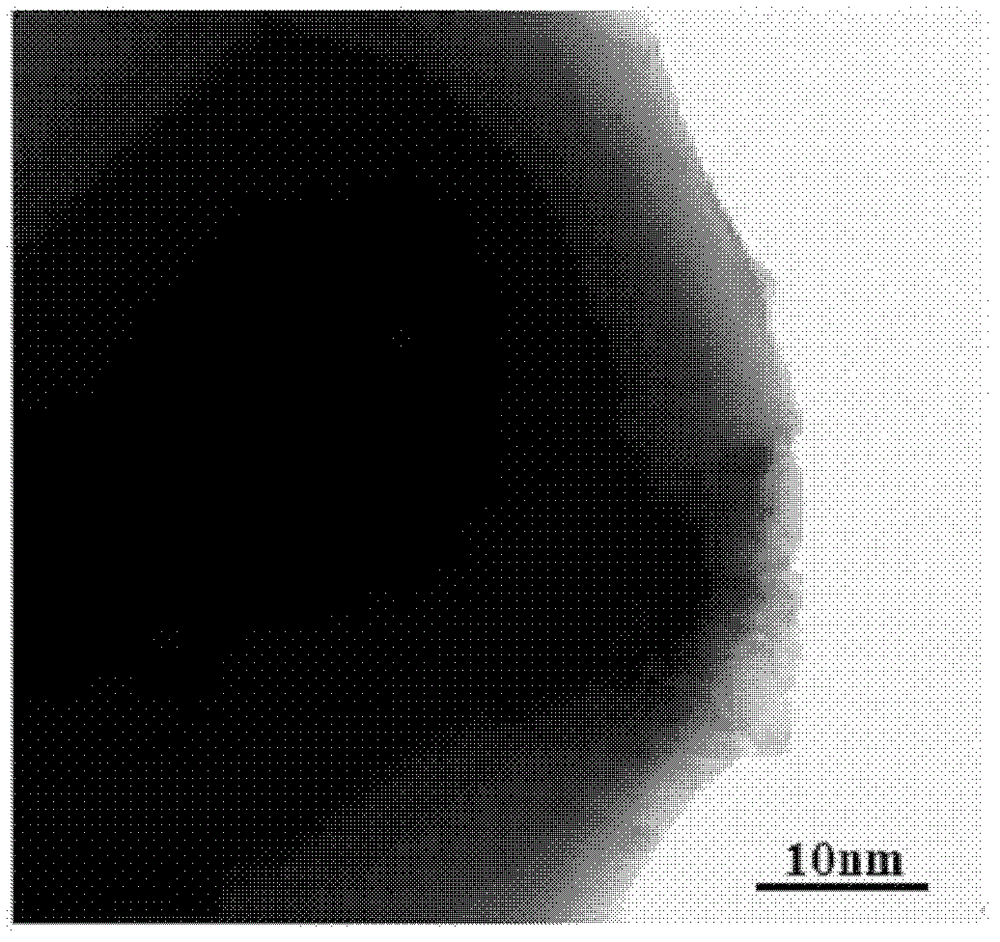

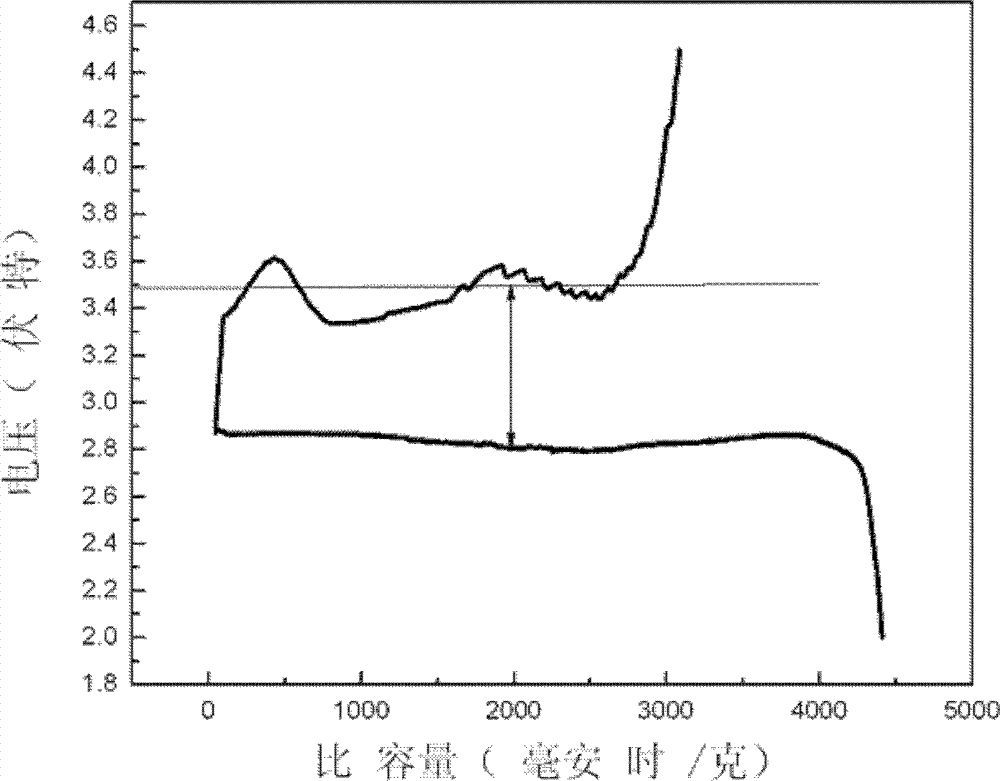

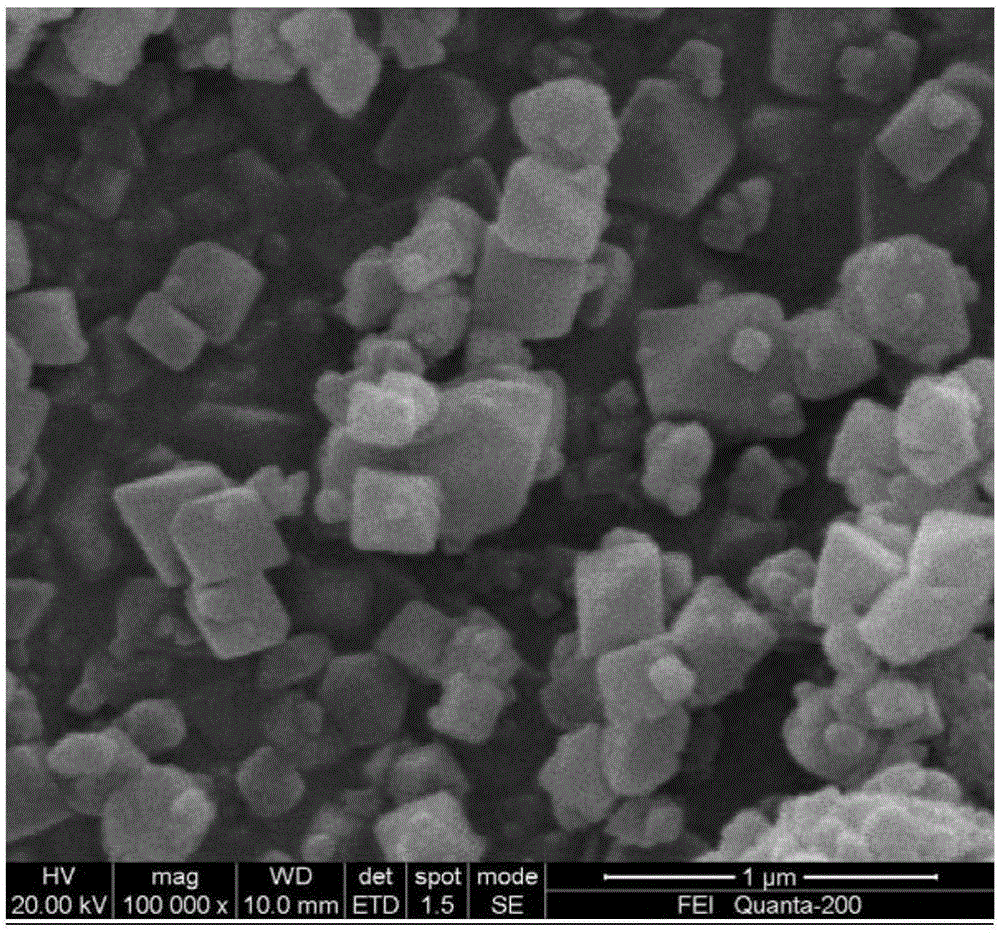

Core-shell structure electric catalyst material for lithium air batteries and preparation method thereof

InactiveCN102683726BImprove stabilityImprove conductivityPhysical/chemical process catalystsCell electrodesInternal resistanceLithium-ion battery

The invention relates to a core-shell structure electric catalyst material for lithium air batteries and a preparation method thereof. The electric catalyst material comprises a core layer formed by a transition metal oxide and a shell layer formed by a transition metal nitride, the core layer is a hollow or solid core, the inner diameter of the core layer is 0-50nm, the outer diameter of the core layer is 30-500nm, the thickness of the shell layer is 10-200nm, and the mass of the shell layer accounts for 10-40% of the mass of the electric catalyst material. The preparation method includes that the hollow or solid transition metal oxide is prepared by adopting a liquid phase method. On the basis, transition metal salt is nitrogenized directly to be covered on the surface of the transition metal oxide by adopting a nitriding sintering method, and the core-shell material is prepared by covering the transition metal nitride on the transition metal oxide. The core-shell material has good electrical conductivity and stability, can effectively reduce charging and discharging polarization of the lithium air batteries, reduces internal resistance of the batteries, has good discharging capacity simultaneously, is simple in preparation process method, convenient to operate and low in cost, and achieves large-scale production easily.

Owner:CENT SOUTH UNIV

Lithium peroxide electrode and preparation method and application thereof

InactiveCN108110384AMitigate or avoid loop decayMitigate or avoid sudden failureFuel and secondary cellsCell electrodesLithium oxideLithium–air battery

The invention relates to a lithium peroxide electrode and a preparation method and an application thereof. The lithium peroxide electrode comprises a substrate and lithium peroxide deposited in the substrate; the substrate comprises a conductive framework and a porous layer formed on the conductive framework; and the conductive framework is made of a metal material. The preparation method of the lithium peroxide electrode disclosed in the invention has the characteristics of simple process, low cost and less pollution, and the problems of corrosion loss, high polarization and the like of an oxygen electrode carbon carrier and a catalyst in the conventional lithium oxide battery or a lithium air battery can be avoided; and meanwhile, the lithium peroxide electrode is low in cost and large-scale production can be realized easily.

Owner:ZHANGJIAGANG SMARTGRID FANGHUA ELECTRICAL ENERGY STORAGE RES INST

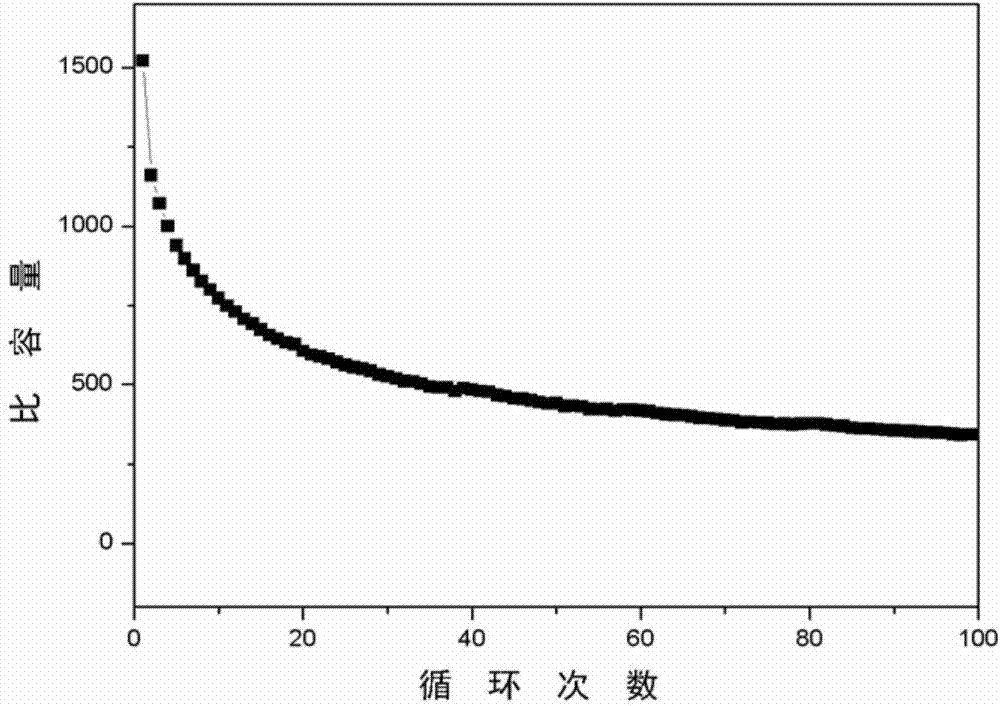

Micro/nano structured cathode material for lithium air batteries

InactiveCN102856611BImprove electrochemical activityRealize NanoizationHybrid cell detailsNano catalystFiber

The invention discloses a micro / nano structured cathode material for lithium air batteries. The cathode material comprises hollow porous composite fibers, is obtained by compounding catalyst nano particles used for lithium air battery positive electrode reaction with a hollow micron-sized carbon fiber carrier, the carbon fiber tube wall comprises a plurality of nano pores which are interconnected, and the catalyst nano particles are dispersedly loaded on the carbon fiber tube wall and in the pores. The prepared cathode material can provide sufficient active substance reaction zones, simultaneously the porous structure of the tube wall increases the reaction activity of the active substance, and the hollow structure in the tube guarantees the unblocked delivery channel of oxygen. According to the invention, the cathode material disclosed herein has a structure of hollow in the tube and porous on the tube wall; the micro / nano structured cathode material formed by compounding the nano catalyst, thus the material has excellent electrical conductivity, can effectively raise the charge and discharge capacity of the lithium air batteries, reduce the polarization of charge and discharge, raise the high rate discharge capability and power density of the lithium air batteries are raised, the battery inner resistance is reduced, thus the material disclosed herein is an ideal cathode material.

Owner:CENT SOUTH UNIV

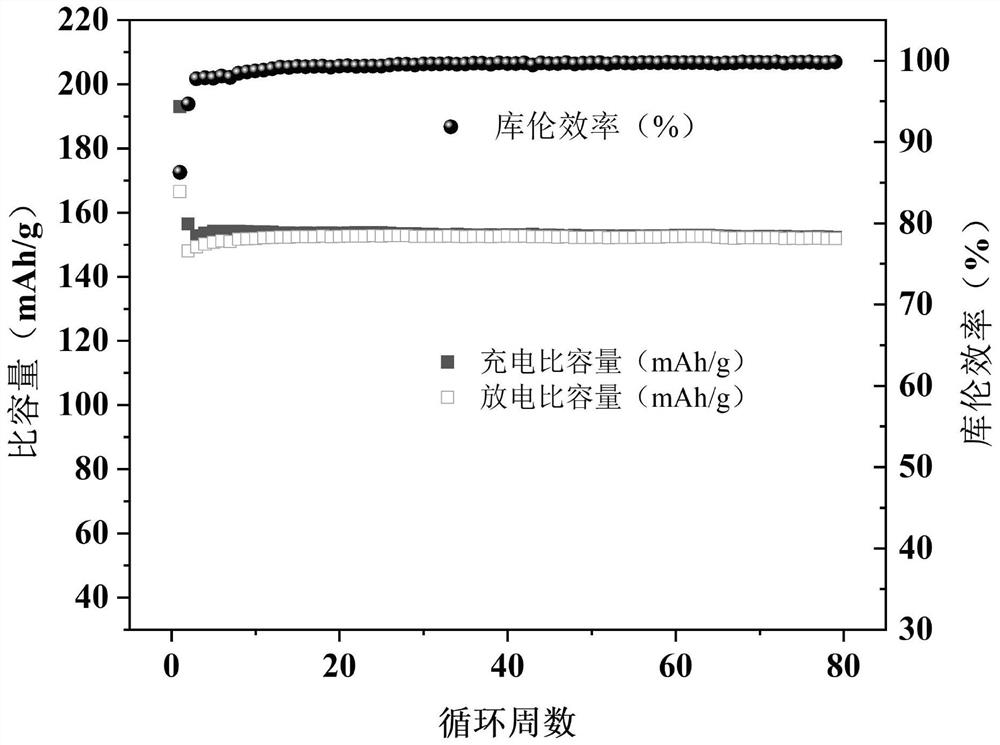

A kind of high voltage high volume energy density long life lithium ion battery and its preparation method

ActiveCN106252569BImprove cycle lifeImprove conductivityCell seperators/membranes/diaphragms/spacersCell electrodesPolyolefinCarbon nanotube

The invention provides a high-voltage, high-volume-energy-density, long-life lithium-ion battery and a preparation method thereof. The battery includes an aluminum-plastic packaging film for an outer casing of the lithium-ion battery, a positive electrode plate, a negative electrode plate, an isolation film, an electrolyte, Positive and negative electrode tabs; the conductive agent used in the positive electrode tab is carbon nanotubes (CNTs), and the isolation film includes a polyolefin isolation film base and Al 2 O 3 and polyvinylidene fluoride (PVDF) mixed coating, the surface of the polyolefin isolation film base is coated with Al 2 O 3 and polyvinylidene fluoride (PVDF). The high voltage, high volume energy density and long life lithium ion battery of the present invention not only has a volume energy density of ≥700Wh / L, but also has good electrochemical performance and safety performance, outstanding cycle performance, and a normal temperature life of up to 800 cycles with capacity retention above 80%.

Owner:TIANJIN ENERGIES

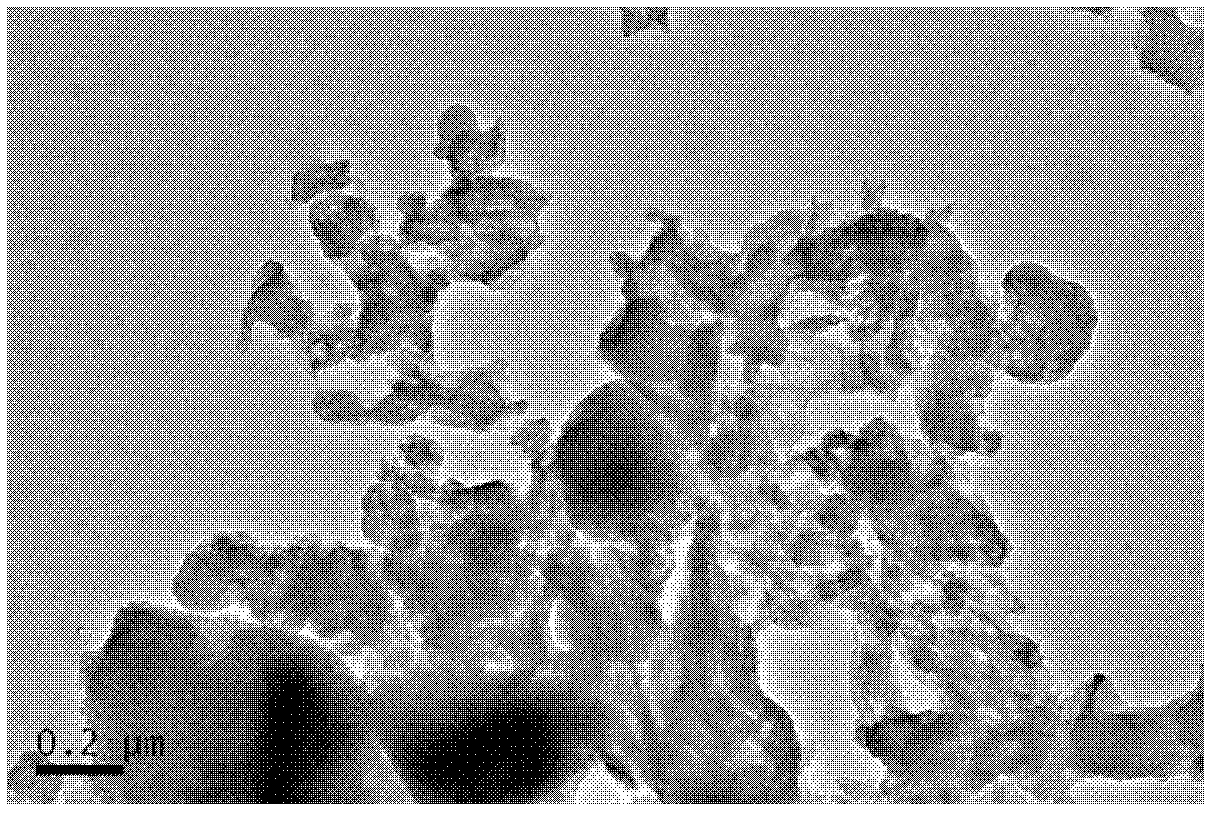

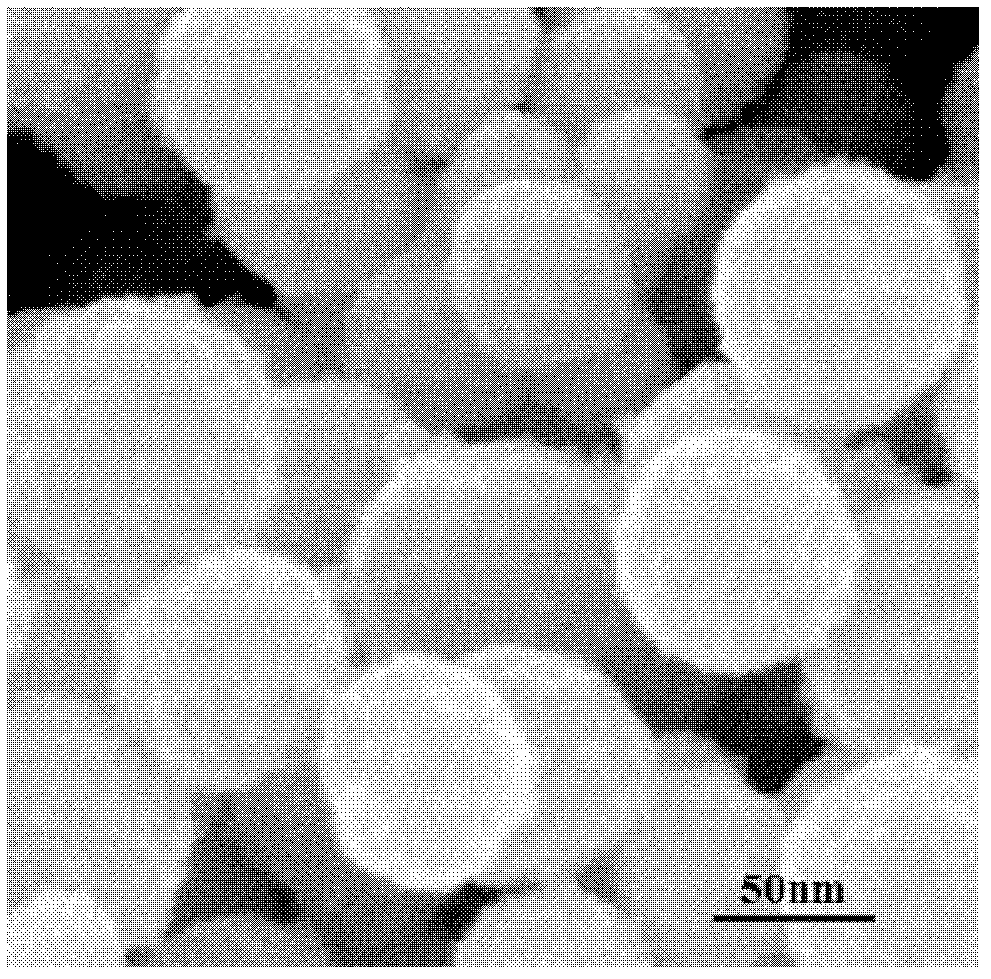

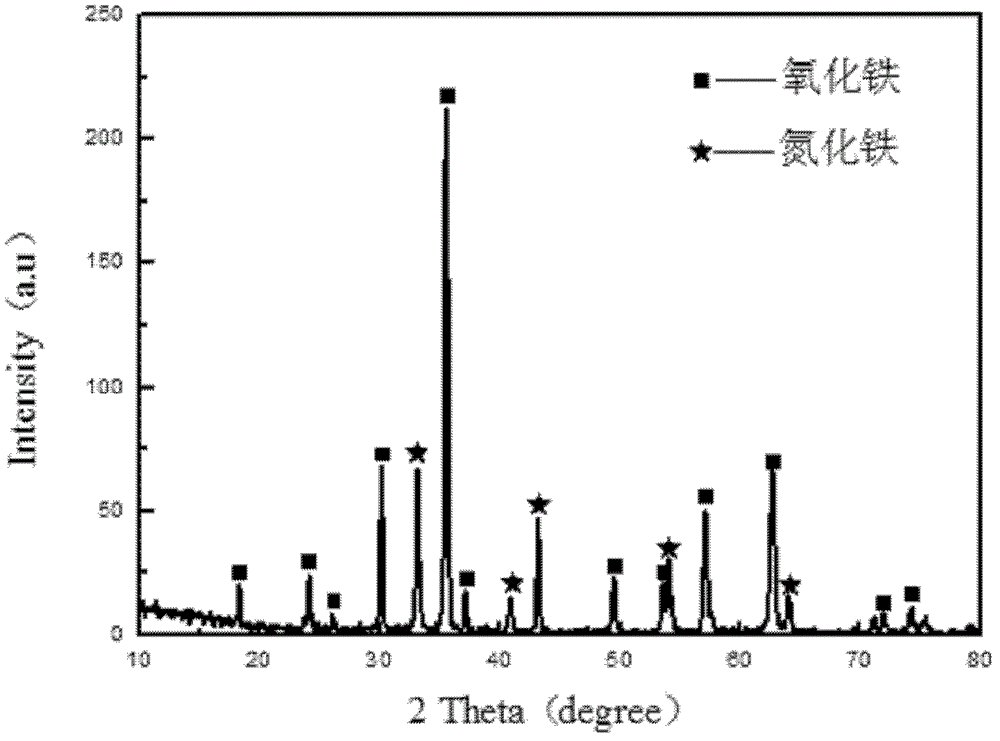

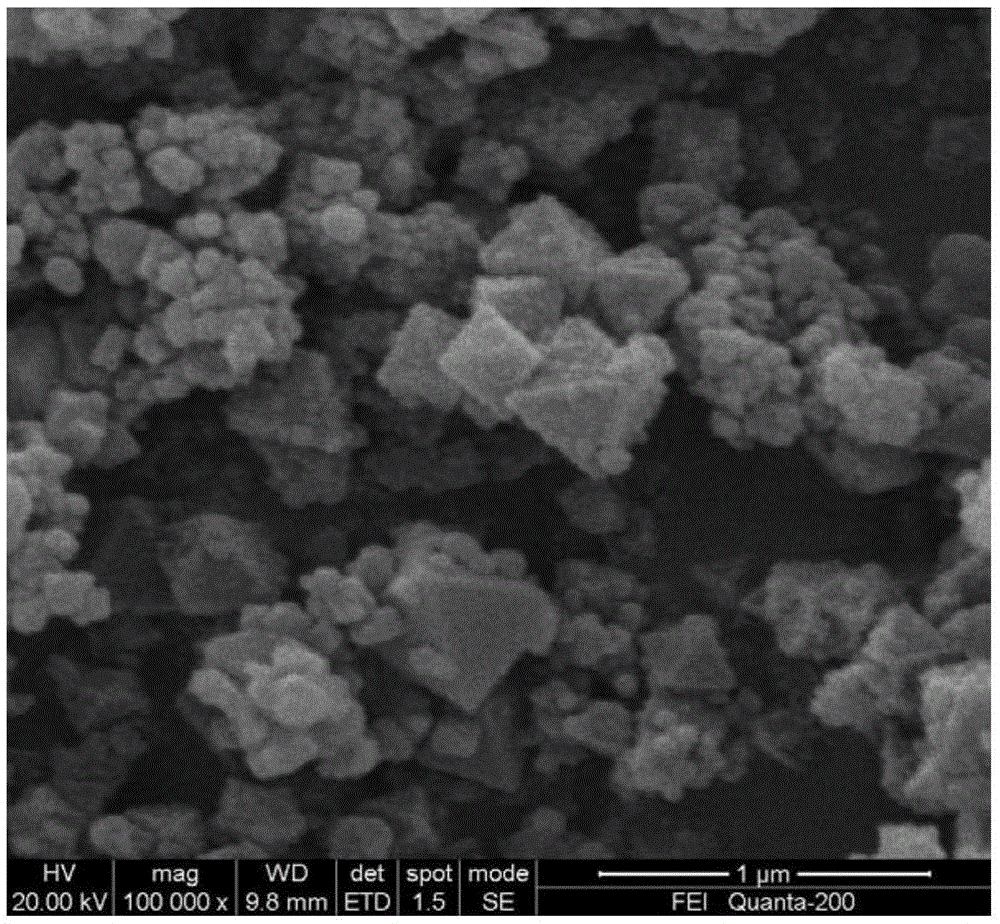

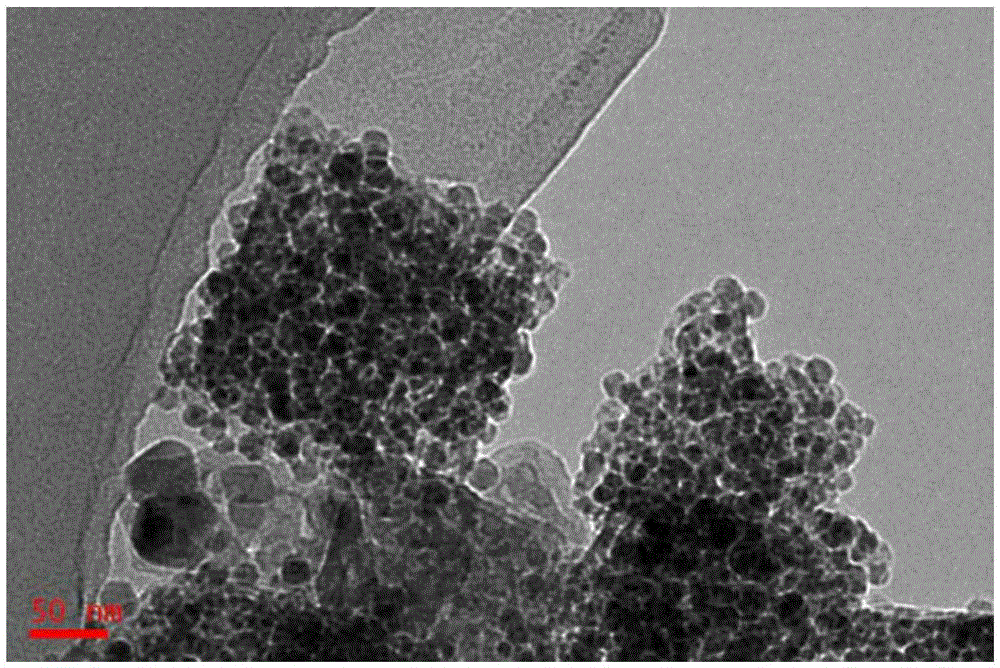

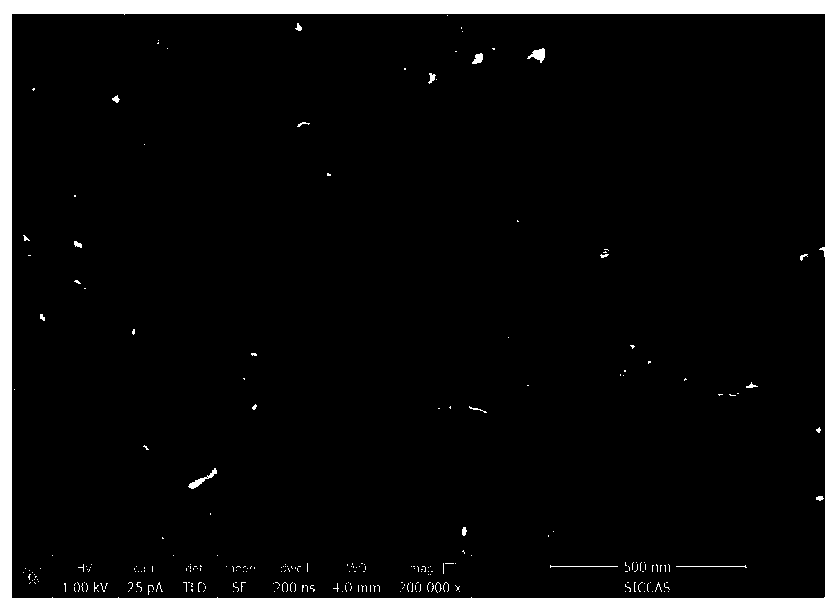

A kind of nano-iron nitride-carbon composite catalyst for positive electrode of lithium-air battery and preparation method thereof

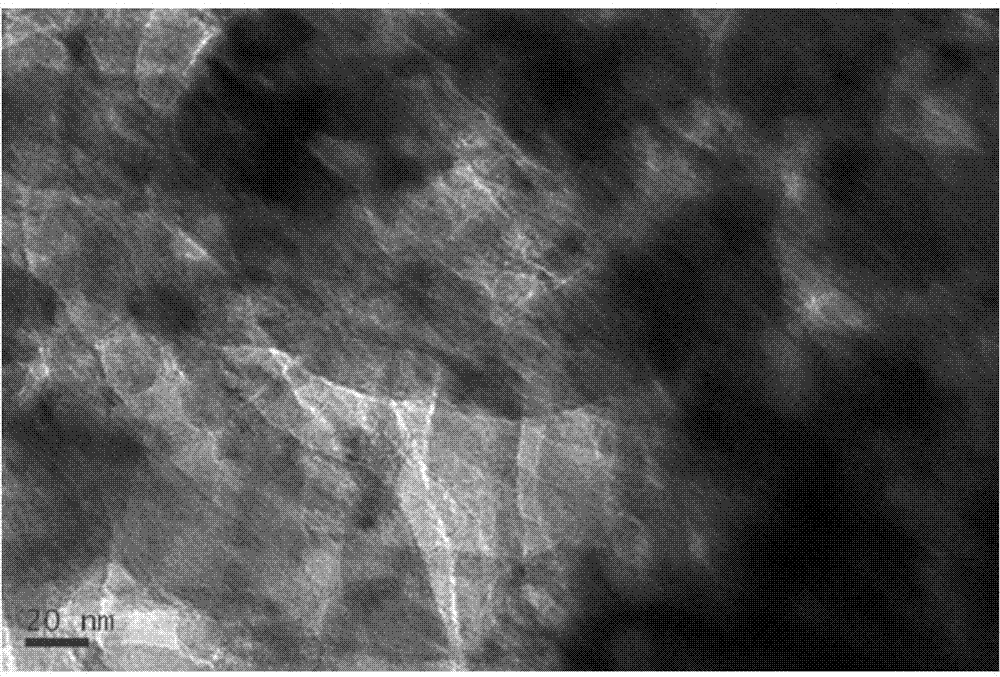

ActiveCN103794806BLarge specific surface areaHigh porosityMaterial nanotechnologyFuel and secondary cellsPorosityCarbon composites

The invention relates to a nano iron nitride-carbon composite catalyst for a lithium-air battery and a preparation method of the composite catalyst. The method comprises the steps of feeding iron salt, organic ligand and a surface active agent into a solvent, and carrying out heating reflux; mixing the obtained nano-sized mesoporous metal organic framework complex and a nitrogenous organic compound, and carrying out heat treatment on the mixture in the presence of ammonia gas to realize carbonization and nitridation by one step. The catalyst is formed by compounding nanoscale primary iron nitride particles and carbon material; carbon covers and partly covers the surfaces of the nanoscale primary iron nitride particles; rich mesoporous gaps exist among the stacked nanoscale primary iron nitride particles. The rich mesoporous structure of a precursor is maintained by the catalyst, the catalyst has large specific surface area and high porosity, and is beneficial to diffusing oxygen molecules into the catalyst material particles, so that the contact between oxygen and the catalyst is promoted, and the utilization rate of the catalyst is increased; the electrical conductivity is effectively improved by the carbon material on the surfaces of the particles; the nano iron nitride-carbon composite catalyst is good in stability, so that the catalytic performance is well exerted. The charge and discharge polarization of the lithium-air battery is effectively reduced; furthermore, the method is simple and convenient, the operation is easy, the cost is low, and large-scale production can be easily implemented.

Owner:CENT SOUTH UNIV

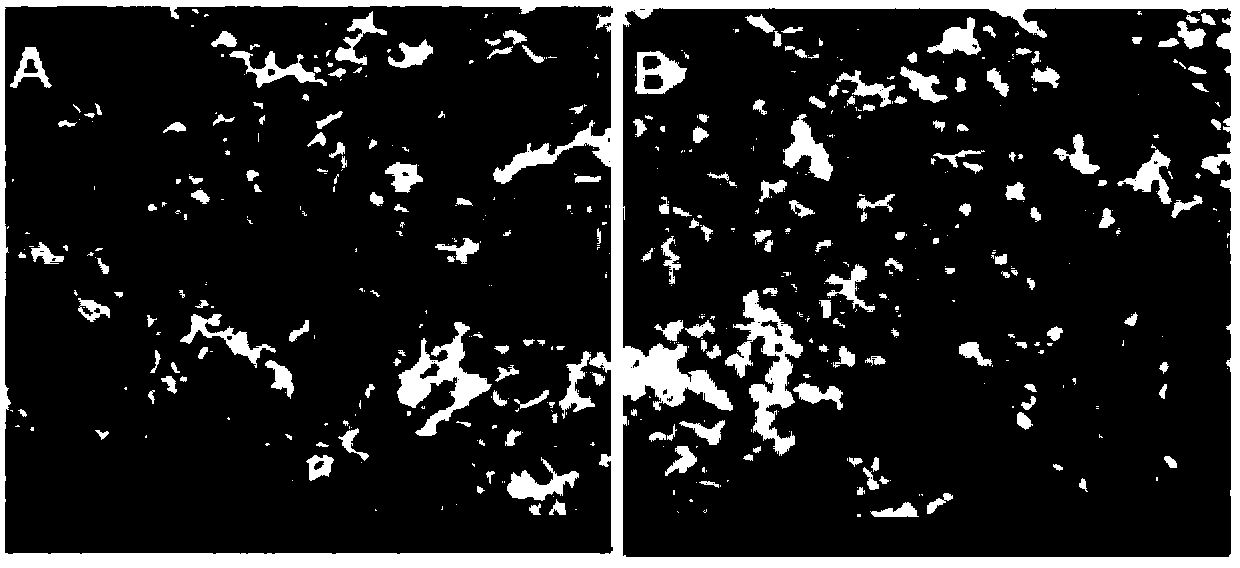

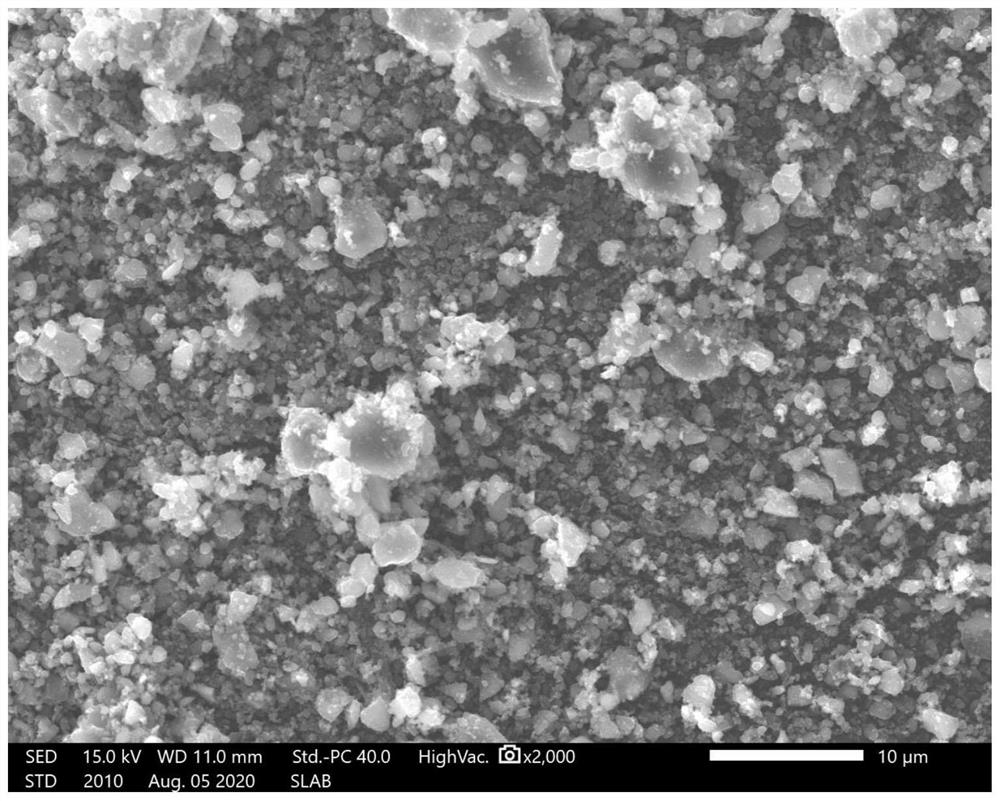

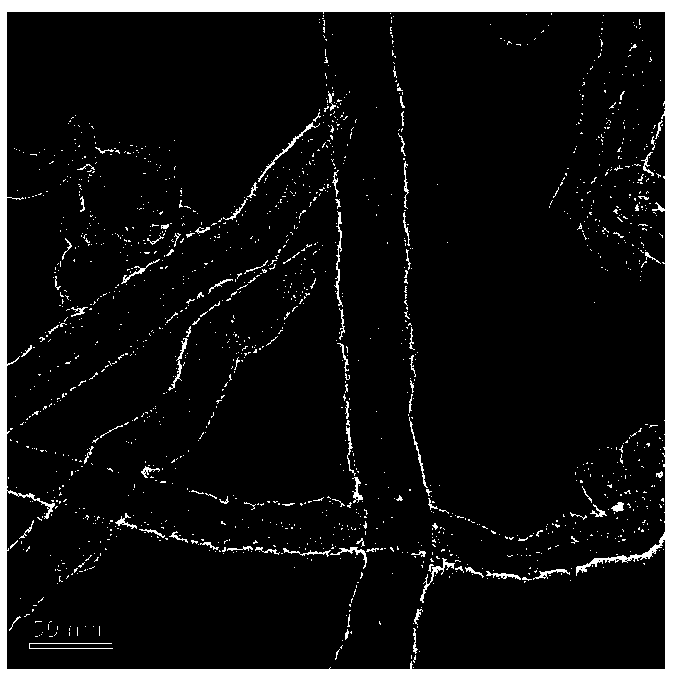

A kind of porous carbon material for positive electrode of lithium-air or lithium-oxygen battery

ActiveCN104518226BShorten the diffusion distanceImprove space utilizationCell electrodesCarbon preparation/purificationLithium oxidePorous carbon

A porous carbon material for positive electrodes of lithium-air or lithium-oxygen batteries. The particle size of the carbon material is 1-30um. The particle itself is a honeycomb-like porous structure composed of carbon sheets. There are two kinds of holes in the interior, one is the staggered through holes composed of carbon sheets as the hole wall, and the other is the holes evenly distributed in the hole wall; the staggered through holes are mainly the second type of pore diameter ranges from The pores of 90nm and 100-500nm account for more than 80% of the pore volume of the through-hole, the pore volume ratio of the two is 1:10-10:1, and the thickness of the carbon sheet is 2-50nm; the pores in the pore wall are mainly Pores with a pore diameter ranging from 1 to 10 nm account for more than 90% of the inner pore volume of the pore wall. The carbon material can effectively improve the discharge specific capacity, voltage platform and rate discharge capability of the battery, thereby improving the energy density and power density of the lithium-air battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of positive electrode material of lithium-sulfur battery and preparation method thereof

ActiveCN103456929BImprove cycle performanceIncrease profitMaterial nanotechnologyCell electrodesHigh rateLithium–sulfur battery

The invention discloses an anode material of a lithium-sulfur battery and a preparation method thereof. The anode material is formed by the compounding of elementary sulfur and porous three-dimensional grading carbon. The preparation method comprises the steps of preparing a precursor compound of the porous three-dimensional grading carbon with a solvothermal method, carbonizing to obtain the porous three-dimensional grading carbon, then compounding with the sulfur to obtain the anode material of the lithium-sulfur battery. The preparation method is simple and low in cost, the prepared anode material of the lithium-sulfur battery has high sulfur containing capability, and high ion transmission capability and conductivity, and can improve the high-rate capability and the high cycle performance of the lithium-sulfur battery.

Owner:CENT SOUTH UNIV

Carbon-based composite positive electrode material for lithium-air battery and preparation method thereof

The invention relates to a carbon-based composite positive electrode material for a lithium-air battery and a preparation method of the carbon-based composite positive electrode material. The carbon-based composite positive electrode material comprises a carbon material, a protection layer and precious metal particles, wherein the protection layer wraps the surface of the carbon material and is composed of an ionic liquid, and the precious metal particles are dispersed in the ionic liquid in a nanoparticle form so as to modify the surface of the carbon material.

Owner:江苏先进无机材料研究院

Electrolyte and lithium-ion battery

ActiveCN112397786BLow costLower internal resistanceSecondary cellsOrganic electrolytesElectrolytic agentOrganic solvent

The application provides an electrolyte solution and a lithium ion battery, which belong to the technical field of batteries. The electrolytic solution includes an organic solvent, lithium salt dissolved in the organic solvent, and an auxiliary agent. The auxiliary agent is selected from one or more of S element, B element, P element and reducing compounds that can release specific negative ions in the electrolyte, and the specific negative ion is selected from one or more of S negative ions, B negative ions and P negative ions kind. Lithium ion batteries include this electrolyte. Specific types of additives can effectively reduce the potential of lithium-containing compounds when they decompose; the way of adding additives to the electrolyte ensures that the battery has better cycle stability and has good applicability in the battery production process.

Owner:SONGSHAN LAKE MATERIALS LAB +1

Porous carbon materials for positive electrodes of lithium-air batteries

ActiveCN103855412BShorten the diffusion distanceImprove space utilizationFuel and secondary cellsCell electrodesAir cellPorous carbon

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

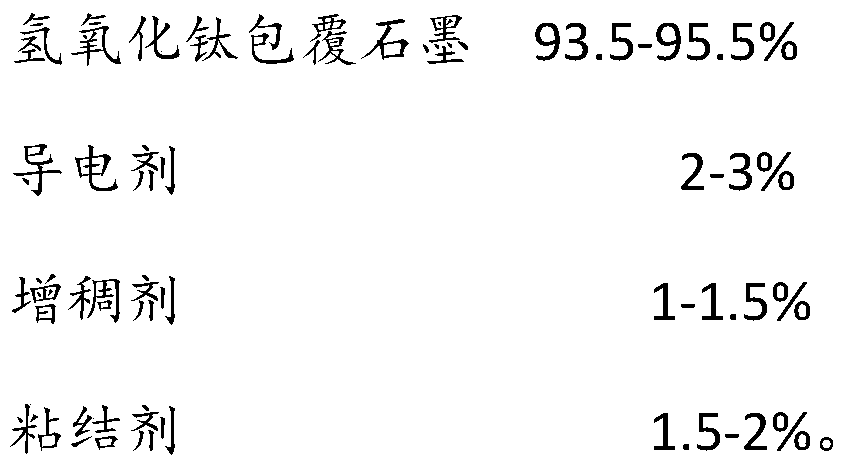

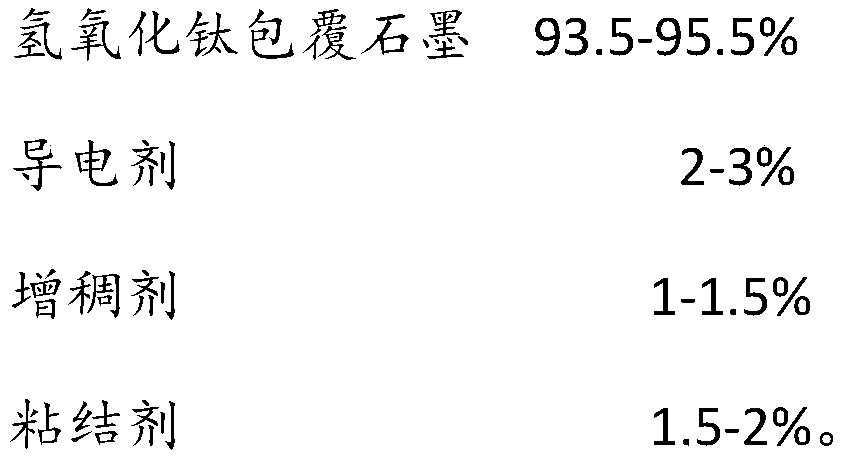

Slurry for negative electrode pole piece and preparation method thereof, negative electrode piece, and lithium ion battery

PendingCN110311105AHigh power outputImprove discharge performanceMaterial nanotechnologyFinal product manufacturePole pieceSlurry

The invention relates to the field of a lithium ion battery and discloses slurry for a negative electrode pole piece and a preparation method thereof, the negative electrode piece and the lithium ionbattery. The slurry includes 46-54% of slurry body and 46-54% of the water by the mass fraction, and the slurry body includes, by the mass fraction, 93.5-95.5% of titanium hydroxide coated graphite, 2-3% of conductive agent, 1-1.5% of thickener and 1.5-2% of binder. The slurry is advantaged in that the power output range of the lithium ion battery assembled with the negative pole piece is greatlyimproved, the wetting effect of the electrolyte on the graphite can be improved, lithium insertion kinetics is improved, charge and discharge polarization phenomena are reduced, moreover, based on semiconductor properties of titanium hydroxide itself, electron conduction is accelerated, a coating material has a nanoparticle size, the tunneling effect is achieved, lithium ion conduction is improved, low temperature power output of a core is optimized, in particular, the rapid discharge capability of the lithium ion battery under the high current is greatly improved.

Owner:桑顿新能源科技(长沙)有限公司

Lithium-air battery cathode uses porous carbon material

ActiveCN103855394BShorten the diffusion distanceImprove space utilizationFuel and secondary cellsCell electrodesPorous carbonElectrical battery

The present invention relates to an application of a graded pore structure porous carbon material in a lithium-air battery. The porous carbon material is characterized in that the porous carbon material has interconnected graded pore structure distribution, wherein the interconnected graded pore structure distribution comprises a mesopore structure for discharge product deposition and a macropore structure for oxygen and electrolyte transmission. According to the present invention, with application of the carbon material as the lithium-air battery electrode material, the space utilization rate of the carbon material during the charge-discharge process can be increased at a maximum, and the discharge specific capacity, the voltage platform and the rate discharge capability of the battery can be effectively increased so as to increase the energy density and the power density of the lithium-air battery; and the preparation process is simple, the material source is wide, the pore structure of the graded pore carbon material can be regulated, the regulation manner is diverse, and the metal / metal oxide doping can be concurrently and easily achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Nitrogen-doped porous carbon material for lithium-air battery cathode

ActiveCN103855365BHigh discharge specific capacityHigh voltage platformFuel and secondary cellsCell electrodesPorous carbonCharge discharge

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com