Core-shell structure electric catalyst material for lithium air batteries and preparation method thereof

A lithium-air battery and electrocatalyst technology, which is applied in the field of electrochemistry, can solve the problems of unsatisfactory specific capacity and cycle performance of batteries, poor conductivity of transition metal oxides, and ineffective reduction of charging voltage, etc., to achieve good electrical conductivity properties, reduce polarization, and promote stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

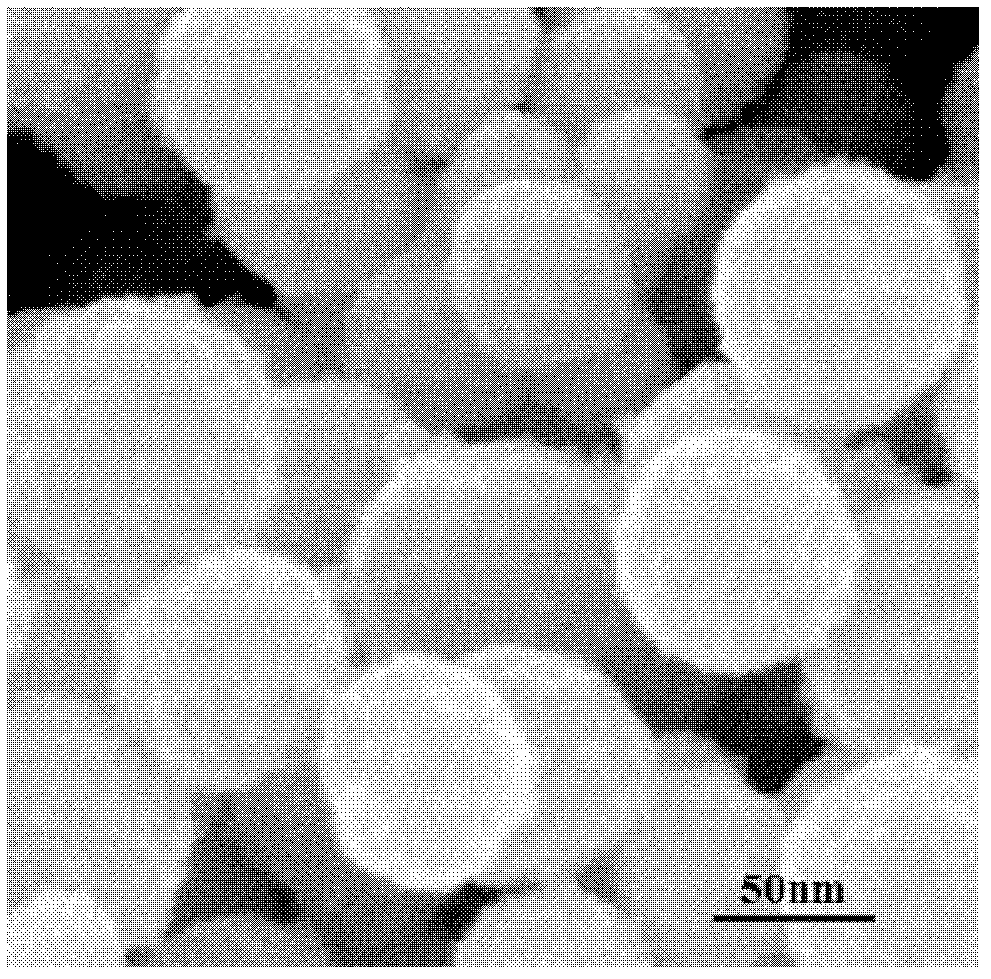

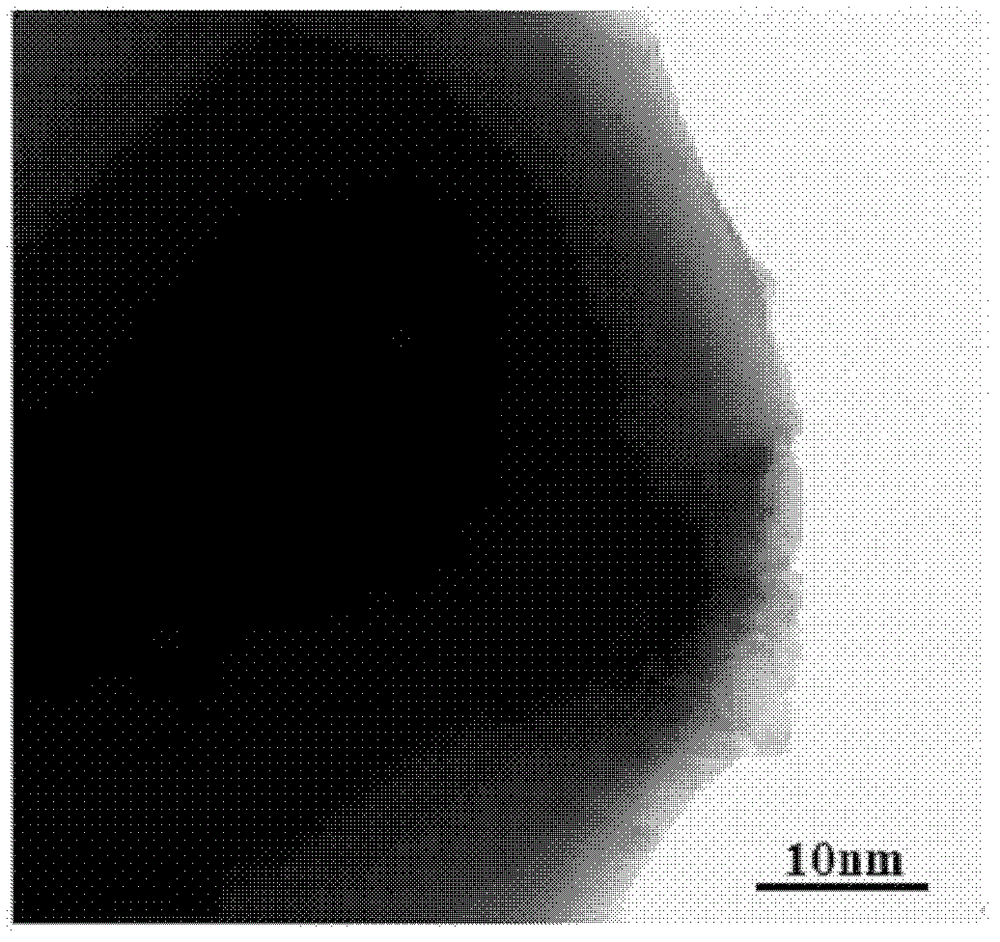

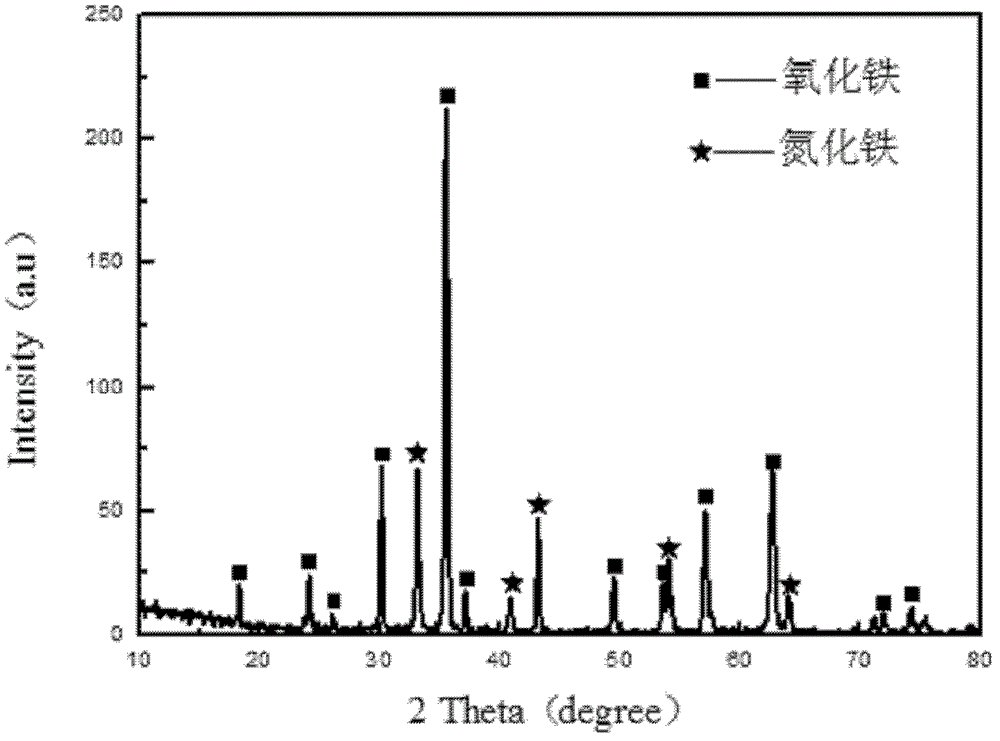

[0043] 1) Preparation of core layer material: at a stirring speed of 400 rpm, add 60 parts of distilled water dropwise to 10 parts of toluene to obtain a transparent microemulsion, add ferric nitrate solution drop by drop, and then ultrasonically oscillate for 1 hour to obtain the weight concentration 5% nuclear layer precursor liquid; at a stirring speed of 1200rpm, slowly dropwise add ammonia water with a concentration of 1.0mol / L to the nuclear layer precursor liquid until the pH is neutral, react at a temperature of 40°C for 4h, filter, Washing and vacuum drying to obtain iron hydroxide solid spheres with a diameter of 40 nm, and then sintering at 350° C. for 3 hours to obtain iron oxide solid spheres with a diameter of 40 nm.

[0044] 2) Shell material preparation: disperse urea and ferric nitrate in deionized water, add iron oxide solid balls, the molar ratio of iron oxide solid balls, urea and ferric nitrate is 3:2:1, stir for 2 hours, and then Drying under vacuum; Nitr...

Embodiment 2

[0048] 1) Preparation of core layer material: Dissolve 5 parts of alkylphenol polyoxyethylene ether in 50 parts of toluene, add 50 parts of distilled water dropwise at a stirring speed of 400rpm to obtain a transparent microemulsion, and add ferric nitrate dropwise Solution, and then ultrasonically oscillate for 0.5 hours to obtain a nuclear layer precursor liquid with a weight concentration of 2%; at a stirring speed of 1000rpm, slowly add ammonia water with a concentration of 1.0mol / L to the nuclear layer precursor liquid until the pH is neutral , reacted at a temperature of 30°C for 5h, filtered, washed, and vacuum-dried to obtain iron hydroxide hollow spheres with an inner diameter of 20nm and an outer diameter of 60nm, and then sintered at 500°C for 4h to obtain iron oxide hollow spheres with an inner diameter of 20nm and an outer diameter of 60nm.

[0049] 2) Shell material preparation: disperse urea and ferric nitrate in deionized water, add Fe 2 o 3 Hollow sphere, Fe ...

Embodiment 3

[0054] 1) Preparation of core layer material: Dissolve 5 parts of alkylphenol polyoxyethylene ether in 50 parts of toluene, add 50 parts of distilled water dropwise at a stirring speed of 400rpm to obtain a transparent microemulsion, and add cobalt nitrate dropwise Solution, and then ultrasonically oscillate for 0.5 hours to obtain a nuclear layer precursor liquid with a weight concentration of 2%; at a stirring speed of 1000rpm, slowly add ammonia water with a concentration of 1.0mol / L to the nuclear layer precursor liquid until the pH is neutral , react at a temperature of 30° C. for 5 h, filter, wash, and vacuum-dry to obtain cobalt hydroxide hollow spheres with an inner diameter of 20 nm and an outer diameter of 60 nm. , and then sintered at 350°C for 3h to prepare a hollow sphere of cobalt tetraoxide with an inner diameter of 20nm and an outer diameter of 60nm.

[0055] 2) Shell material preparation: disperse urea and ammonium molybdate in deionized water, add tricobalt t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com