Slurry for negative electrode pole piece and preparation method thereof, negative electrode piece, and lithium ion battery

A technology of negative pole piece and slurry, which is used in secondary batteries, battery electrodes, non-aqueous electrolyte batteries, etc., can solve the problems of poor kinetic performance, low output power, and slow lithium deintercalation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a slurry for negative pole pieces, the method comprising:

[0035] The titanium hydroxide-coated graphite, the conductive agent, the thickener and the binder are added into the water, the stirring speed is 2500-4000r / min, and the stirring is carried out for 200-280min to obtain the slurry.

[0036] A negative pole piece, including copper foil and the above-mentioned slurry, the above-mentioned slurry is coated on the copper foil, and dried to obtain a negative pole piece; then the negative pole piece can also be rolled and die-cut to obtain an assembleable The negative pole piece; generally, the thickness of the selected copper foil is 8-12μm.

[0037] A lithium-ion battery, comprising a ternary positive electrode sheet, a diaphragm, an electrolyte and the above-mentioned negative electrode sheet, and the excess of the negative electrode is 1.15-1.2. Among them, the ternary positive electrode sheet is a commonly used nickel-cobalt-manganese oxide...

specific Embodiment 1

[0039] A kind of slurry for negative pole piece, slurry comprises according to mass fraction:

[0040] Paste 46%

[0041] water 54%;

[0042] Described slurry comprises by mass fraction:

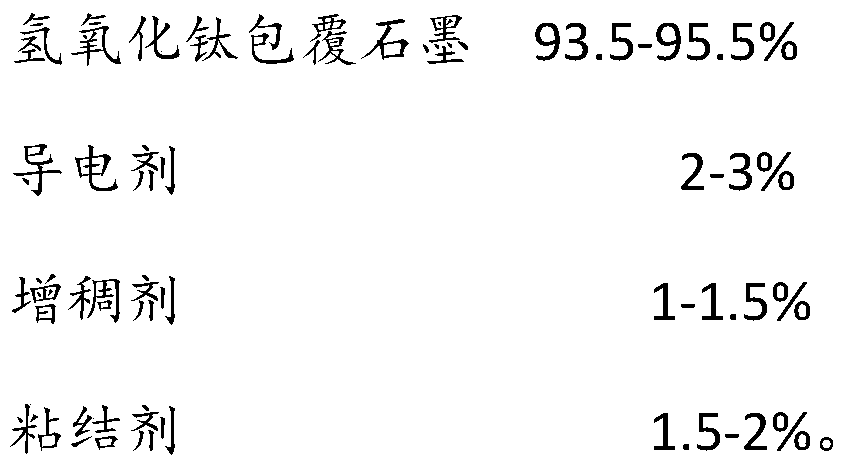

[0043]

[0044] Among them, the preparation method of titanium hydroxide-coated graphite is: adding graphite and ethanol solution into water, heating to 400°C, stirring ultrasonically for 3 hours to prepare a suspension with a mass concentration of 40%; adding a mass concentration of 10% sodium hydroxide solution, then dropwise add 10% titanium sulfate solution, ultrasonically disperse and control the pH value to 9, and heat-treat for 3 hours at 800°C to obtain coated graphite; use the reacted coated graphite Repeated washing with pure water until the filtrate is neutral, and then microwave drying to obtain titanium hydroxide coated graphite. Among them, the D50 of graphite is 8μm, and the specific surface area is 1.6m 2 / g, the tap density is 1g / cm 3 ; The coating amount of titanium...

specific Embodiment 2

[0050] A kind of slurry for negative pole piece, slurry comprises according to mass fraction:

[0051] Paste 52%

[0052] water 48%;

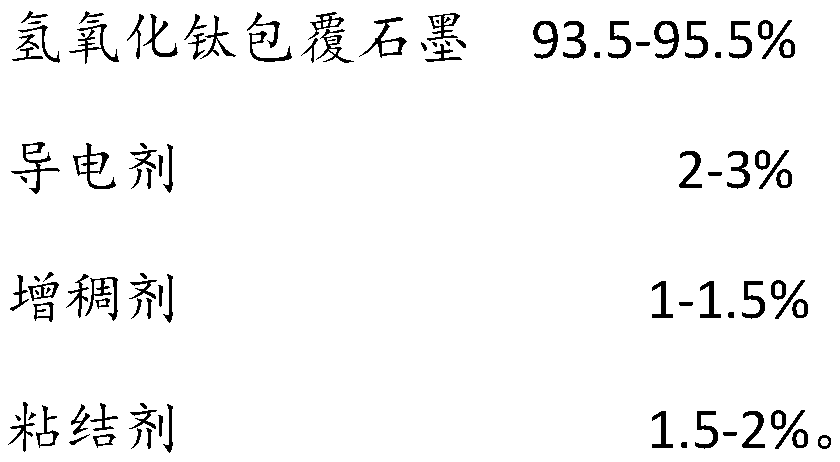

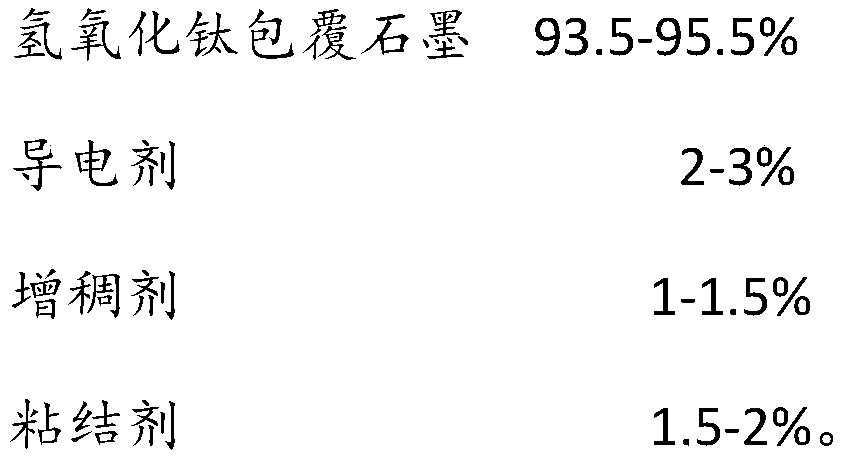

[0053] Described slurry comprises by mass fraction:

[0054]

[0055] Among them, the preparation method of titanium hydroxide coated graphite is: adding graphite and ethanol solution into water, heating to 420°C, stirring ultrasonically for 3 hours to prepare a suspension with a mass concentration of 25%; adding a mass concentration of 10% sodium hydroxide solution, then dropwise add 6%-8% titanium nitrate solution, carry out ultrasonic dispersion and control the pH value to 9, heat treatment at 620°C for 4 hours to obtain coated graphite; the reacted coated graphite The coated graphite was washed repeatedly with pure water until the filtrate was neutral, and then dried by microwave to obtain titanium hydroxide coated graphite. Among them, the D50 of graphite is 7μm, and the specific surface area is 1.4m 2 / g, the tap density is 0.88g / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com