Nitrogen-doped porous carbon material for positive electrode of lithium-air battery

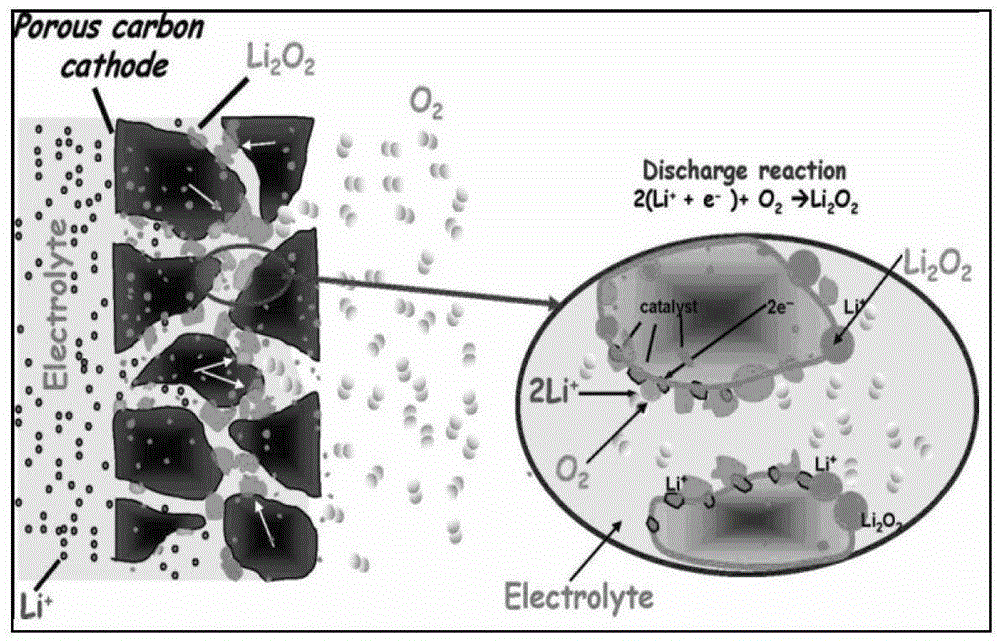

A porous carbon material, air battery technology, applied in battery electrodes, fuel cell-type half-cells and secondary battery-type half-cells, circuits, etc. requirements, experimental conditions and other issues, to achieve the effect of promoting commercial application, improving space utilization, and shortening diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

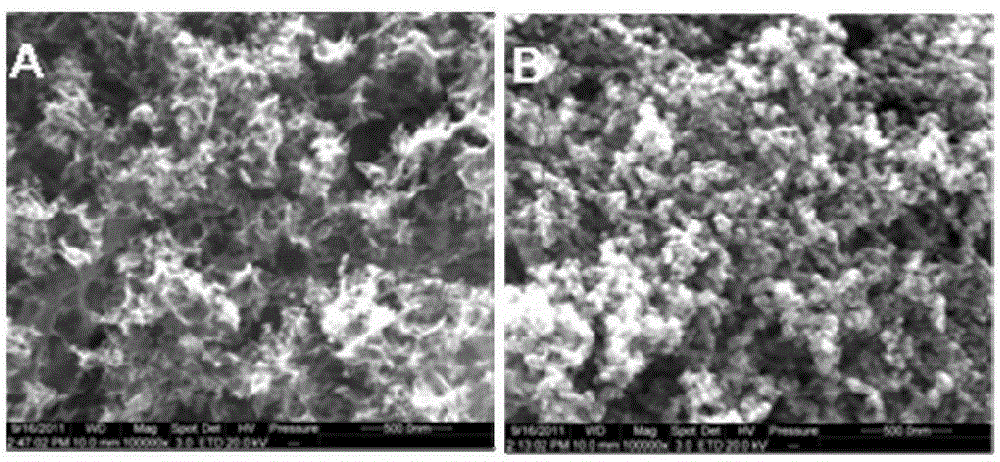

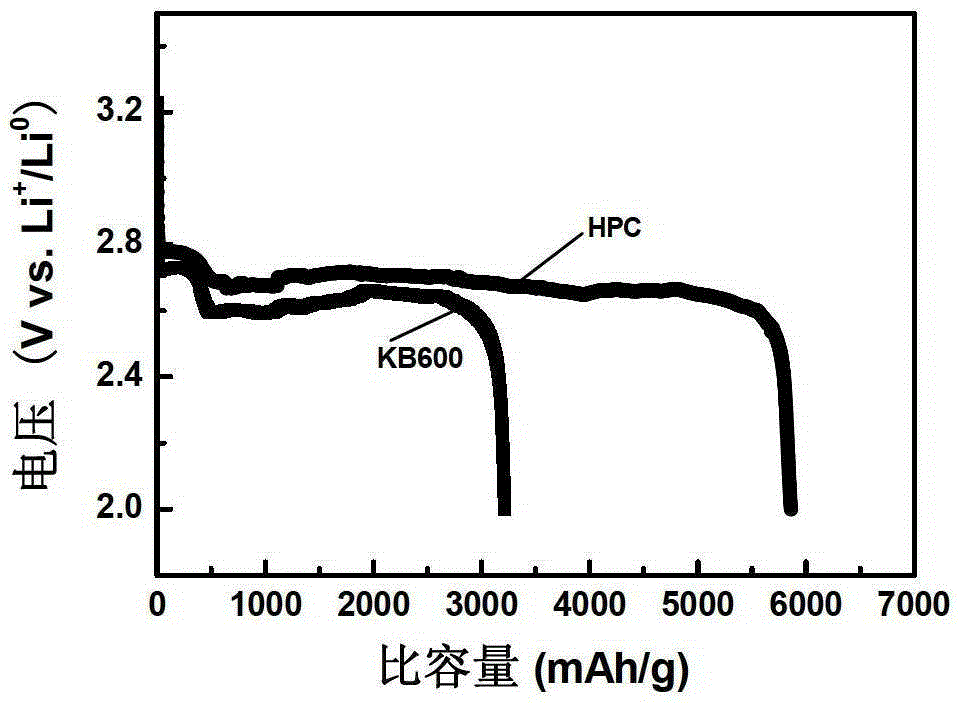

[0033] Nitrogen-doped porous carbon materials with hierarchical pore structure were prepared using nano-magnesium carbonate powder as a template. Accurately weigh 5g of glucose, add 15ml of water and stir until completely dissolved, then add 8g of citric acid and 5g of magnesium carbonate, heat and mechanically stir in a water bath at 80°C to make it completely dispersed, and put it in a vacuum at 80°C after the water is completely evaporated Dry for 24h. Then put the dried product into high temperature tube furnace for carbonization, the atmosphere is NH 3 , the gas flow rate is controlled at 20ml / min. After carbonization at 800°C for 2 hours, the nanoparticle / carbon composite was obtained, and an appropriate amount of 2M dilute hydrochloric acid was added to remove nano-magnesium carbonate. After filtration, vacuum drying at 80°C for 24 hours was obtained to obtain the nitrogen-doped carbon material.

[0034] The positive electrode material structure prepared in Example 1 ...

Embodiment 2

[0039] Nitrogen-doped porous carbon materials with hierarchical pore structure were prepared using nano-calcium carbonate as a template. Accurately weigh 5g of sucrose, add 2g of ethylenediamine into 10ml of water and stir until completely dispersed, then add 5g of calcium carbonate, heat and mechanically stir in a water bath at 80°C to make it completely dispersed, and put it in a vacuum at 80°C after the water is completely evaporated Dry for 24h. Then put the dried product into high temperature tube furnace for carbonization, N 2 Treat at 850℃ for 3h, change CO 2 Purging at 850°C for 1 hour to obtain the nanoparticle / carbon composite, then removing calcium carbonate with an appropriate amount of 2M dilute hydrochloric acid, filtering and drying in vacuum at 80°C for 24 hours to obtain the carbon material.

Embodiment 3

[0041] Commercialized SiO 2 Nitrogen-doped porous carbon materials with hierarchical pore structure were prepared using sol as a template. Accurately weigh 5g of glucose, 1g of citric acid, add 15ml of water and stir until completely dissolved, then add 5g of SiO 2 The sol was mechanically stirred to completely disperse it, heated and mechanically stirred in a water bath at 80°C, and dried under vacuum at 80°C for 24 hours after the water was completely evaporated. Then put the dried product into a high-temperature tube furnace for carbonization, the atmosphere is ammonia, and the gas flow is controlled at 30ml / min. Nano-SiO was obtained by carbonization at 900°C for 3 hours 2 / carbon complex, plus an appropriate amount of 1MHF to remove SiO 2 , after filtration and vacuum drying at 80°C for 24 hours, the carbon material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com