Daylily beef paste and preparation method thereof

A technology for yellow-flowered beef sauce and beef, which is applied in the field of seasoning sauce, can solve the problems of accelerated aging of daylily, oxidative damage of plant body, unfavorable storage of daylily, etc., and achieves the effects of prolonging shelf life, prolonging shelf time, and being beneficial to transportation and sales.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

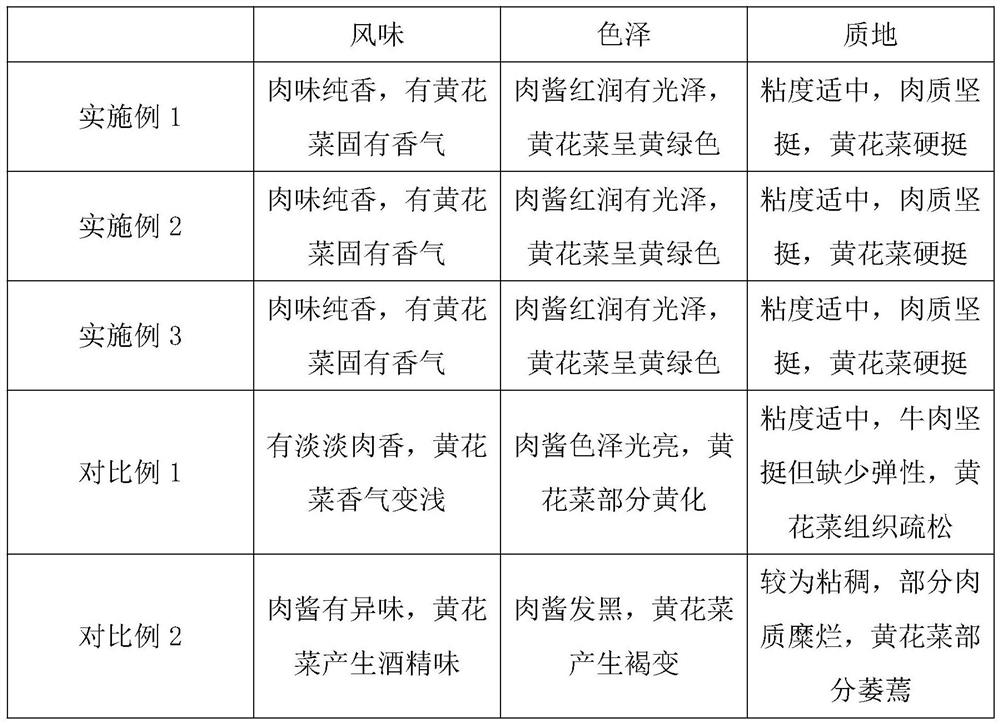

Examples

Embodiment 1

[0026] A yellow flower beef sauce made from the following raw materials: 270g of beef, 90g of day lily, 50g of refined vegetable oil, 12g of soybean sauce, 7g of edible salt, 4g of dried plums, 9g of shiitake mushrooms, 1g of monosodium glutamate, 3g of white sugar, and essence 1.5g, rice wine 2g, potassium sorbate 1g, sodium benzoate 0.5g.

[0027] Before described day lily adds, through pretreatment earlier, concrete steps are as follows:

[0028] (1) Wash the fresh day lily and pour it into a constant temperature water bath, raise the water temperature to 98°C, blanch at a constant temperature for 4 minutes, take out the day lily to dry naturally and lower it to room temperature;

[0029] (2) Send the above-mentioned day lily into a 450Pa vacuum chamber, and carry out cold treatment at 6°C;

[0030] (3) Dissolve food-grade microcrystalline chitosan in water to form an aqueous solution with a mass concentration of 1.5g / 100mL, soak the day lily after cold treatment in the ch...

Embodiment 2

[0036] A yellow flower beef sauce made from the following raw materials: 240g of beef, 80g of day lily, 40g of refined vegetable oil, 10g of soybean sauce, 6g of edible salt, 3g of dried plums, 8g of shiitake mushrooms, 0.5g of monosodium glutamate, 2g of white sugar, essence Material 1g, rice wine 1.5g, potassium sorbate 0.5g, sodium benzoate 0.3g.

[0037] Before described day lily adds, through pretreatment earlier, concrete steps are as follows:

[0038] (1) Wash the fresh day lily and pour it into a constant temperature water bath, raise the water temperature to 98°C, blanch at a constant temperature for 3 minutes, take out the day lily to dry naturally and lower it to room temperature;

[0039] (2) Send the above-mentioned day lily into a 400Pa vacuum chamber, and carry out cold treatment at 4°C;

[0040] (3) Take food-grade microcrystalline chitosan and dissolve it in water to form an aqueous solution with a mass concentration of 1g / 100mL, soak the cold-treated day lil...

Embodiment 3

[0046] A yellow flower beef sauce made from the following raw materials: 300g of beef, 100g of day lily, 60g of refined vegetable oil, 15g of soybean sauce, 8g of edible salt, 5g of dried plum vegetables, 10g of shiitake mushrooms, 1.5g of monosodium glutamate, 4g of white sugar, and essence Material 2g, rice wine 2.5g, potassium sorbate 1.5g, sodium benzoate 0.7g.

[0047] Before described day lily adds, through pretreatment earlier, concrete steps are as follows:

[0048] (1) Wash the fresh day lily and pour it into a constant temperature water bath, raise the water temperature to 98°C, blanch at a constant temperature for 5 minutes, take out the day lily to dry naturally and lower it to room temperature;

[0049] (2) Send the above-mentioned day lily into a 500Pa vacuum chamber, and carry out cold treatment at 8°C;

[0050] (3) Dissolve food-grade microcrystalline chitosan in water to form an aqueous solution with a mass concentration of 2g / 100mL, soak the cold-treated day l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com