A kind of spherical selenium nanoparticle and preparation method thereof

A selenium nano-particle technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that the surface modifier cannot perform sufficient surface modification, and the Se source and reducing agent cannot be fully contacted and reacted , complex synthesis methods, etc., to achieve the effect of reducing particle size, increasing the number of nucleation, and accelerating the nucleation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Weigh 0.11g of selenium dioxide and 0.36g of ascorbic acid, the molar ratio of the two is 1:2, put them into a mortar, mix them, and grind them at 20°C for 1 to 10 minutes until they become a red paste;

[0050] (2) Add 20 mL of deionized water to the red paste obtained by grinding in step (1) to disperse;

[0051] (3) Pour the solution obtained in step (2) into a container, add 47 mg of polyvinylpyrrolidone (PVP) to it, carry out ultrasonic treatment at 20°C and 300W for 60min, and centrifuge at 4°C and 10000r / min after the treatment is completed. The supernatant and the precipitate were freeze-dried separately to finally obtain Se nanoparticles.

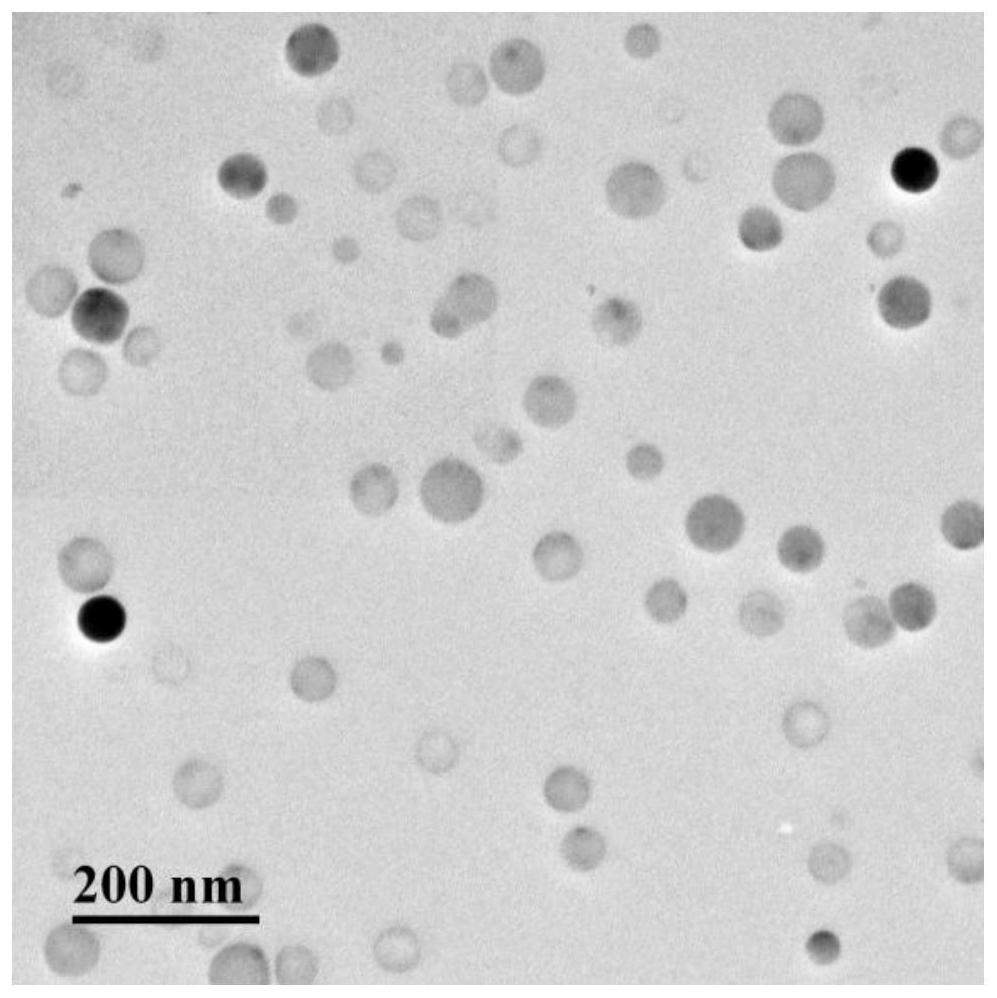

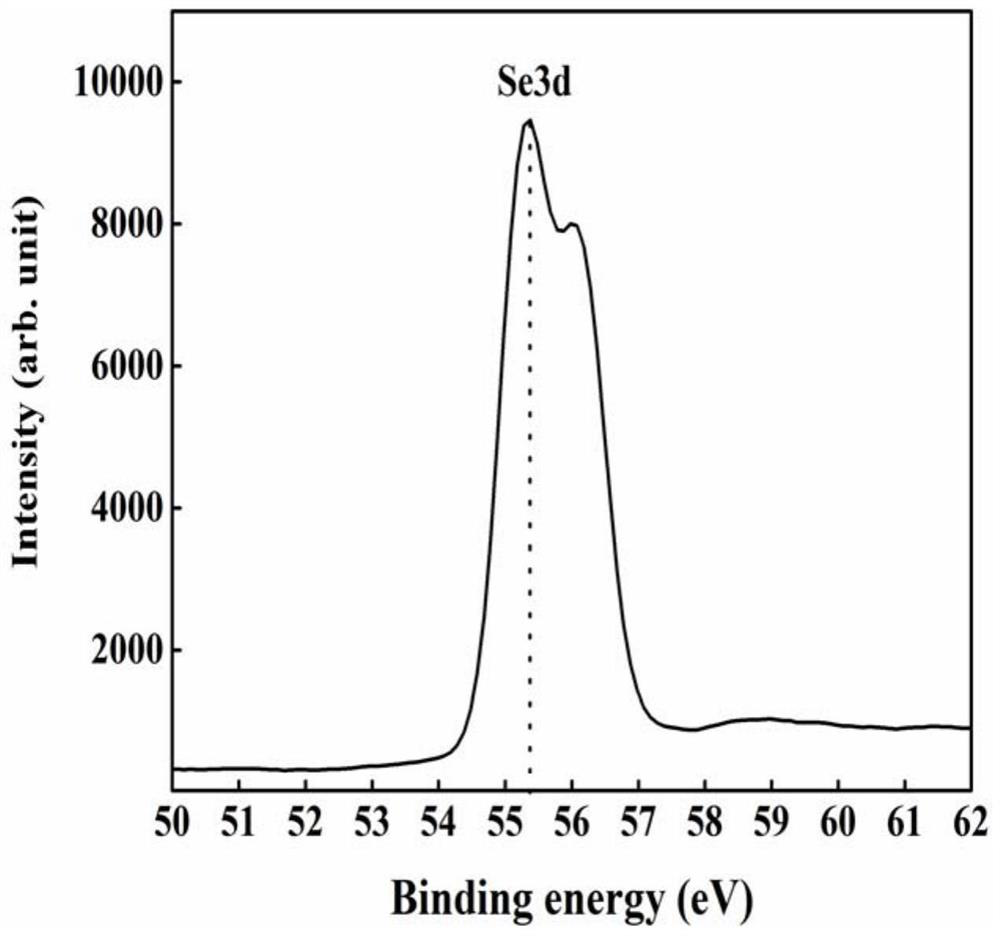

[0052] figure 1 is a TEM photo of Se nanoparticles taken by a transmission electron microscope (TEM), figure 2 It is obtained by X-ray electron spectroscopy (XPS) test; As can be seen from the figure, the selenium nanoparticle size is 40nm, and the shape is spherical ( figure 1 ); wherein the chemical valence of Se i...

Embodiment 2

[0056] Adjust the mol ratio of selenium dioxide and ascorbic acid in embodiment 1 to be 1:1, 1:3, 1:4 respectively, keep the add-on of polyvinylpyrrolidone (PVP) and account for 10% of the total mass of selenium dioxide and ascorbic acid, Other parameters and preparation method all remain unchanged, obtain the character of Se nanoparticle, as shown in table 2:

[0057] Table 2

[0058] Proportion Size (nm) Hydration radius (nm) Surface charge (eV) 1:1 9 200 -0.06 1:3 65 160 1.32 1:4 50 110 2.66

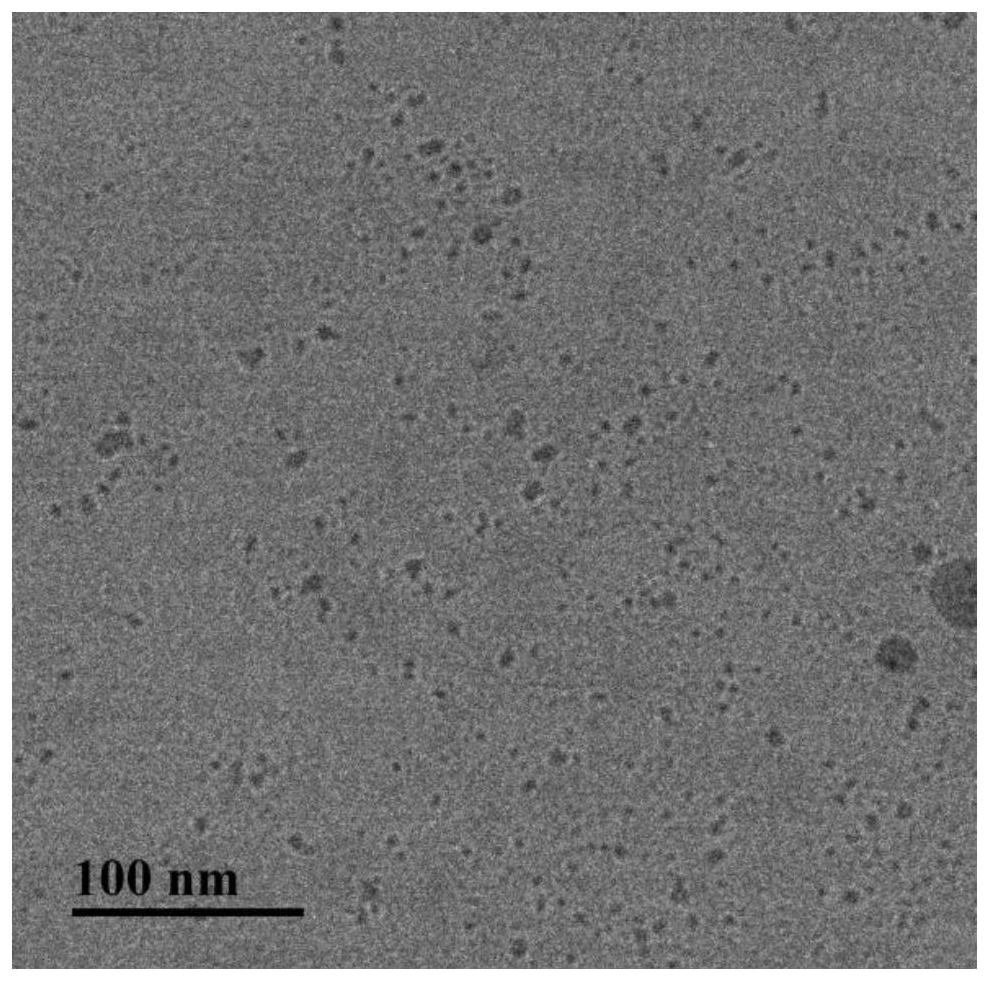

[0059] Figure 3-5 It is the Se nanoparticle TEM photograph prepared in embodiment 2, wherein image 3 The ratio of selenium dioxide and ascorbic acid is a TEM photo of Se nanoparticles prepared in 1:1, Figure 4 TEM photograph of Se nanoparticles prepared for a ratio of selenium dioxide and ascorbic acid of 1:3, Figure 5 TEM photograph of Se nanoparticles prepared for a ratio of 1:4 of selenium dioxide and ascorbic acid. As can be seen f...

Embodiment 3

[0061] Change the Se source in embodiment 1 to be sodium selenite and selenic acid respectively, keep the mol ratio of Se source and ascorbic acid to be 1:2, keep the add-on of polyvinylpyrrolidone (PVP) accounting for selenium dioxide and ascorbic acid total mass 10%, other parameters and preparation method all remain unchanged, obtain the character of Se nanoparticle, as shown in table 3:

[0062] table 3

[0063] Proportion Size (nm) Hydration radius (nm) Surface charge (eV) Sodium Selenite 50 140 -1.08 selenic acid 40 120 1.13

[0064] Figure 6 It is the Se nanoparticle TEM photograph (selenium source is sodium selenite) prepared in embodiment 3, Figure 7 It is a TEM photo of Se nanoparticles prepared in Example 3 (the selenium source is selenic acid). The particle size of selenium nanoparticles obtained by changing the selenium source will be different. When selenic acid is used as the selenium source, the surface of the selenium n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com