Silicon oxide/carbon composite anode material and preparation method thereof and lithium ion battery

A silicon oxide and negative electrode material technology, applied in the field of energy storage, can solve the problems of cycle performance, rate performance, discharge capacity, limited commercial application, poor cycle performance of batteries, etc., and achieve excellent cycle stability and good electrochemical performance. The effect of improving performance and electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

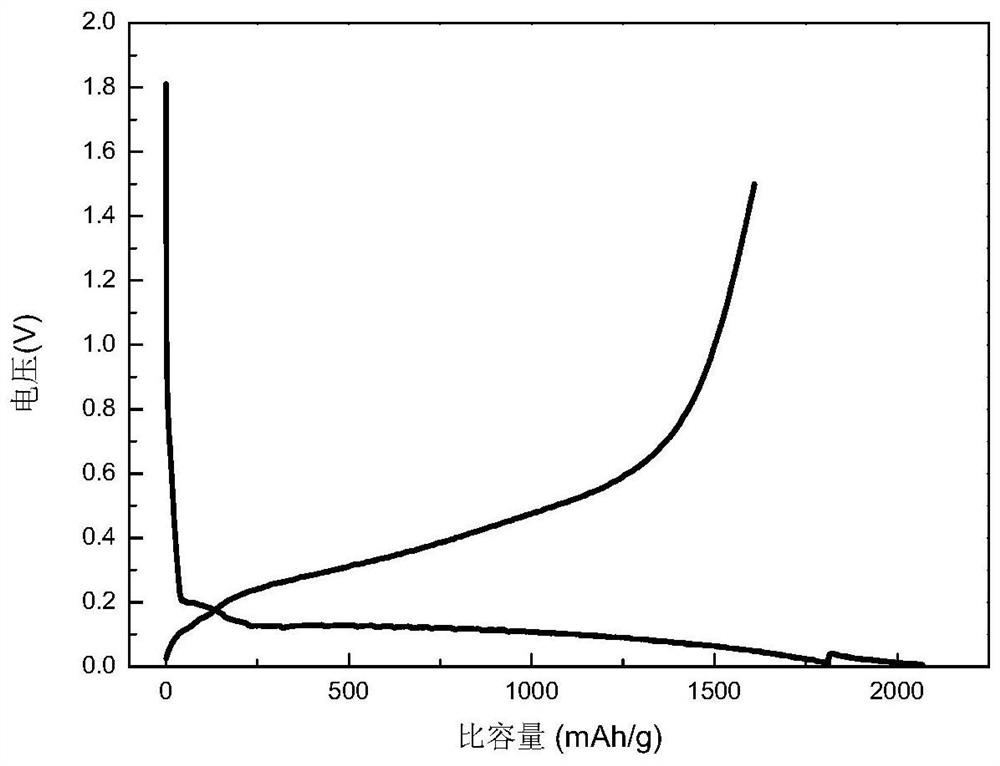

[0095] This embodiment prepares silicon oxide / carbon composite negative electrode material according to the following method:

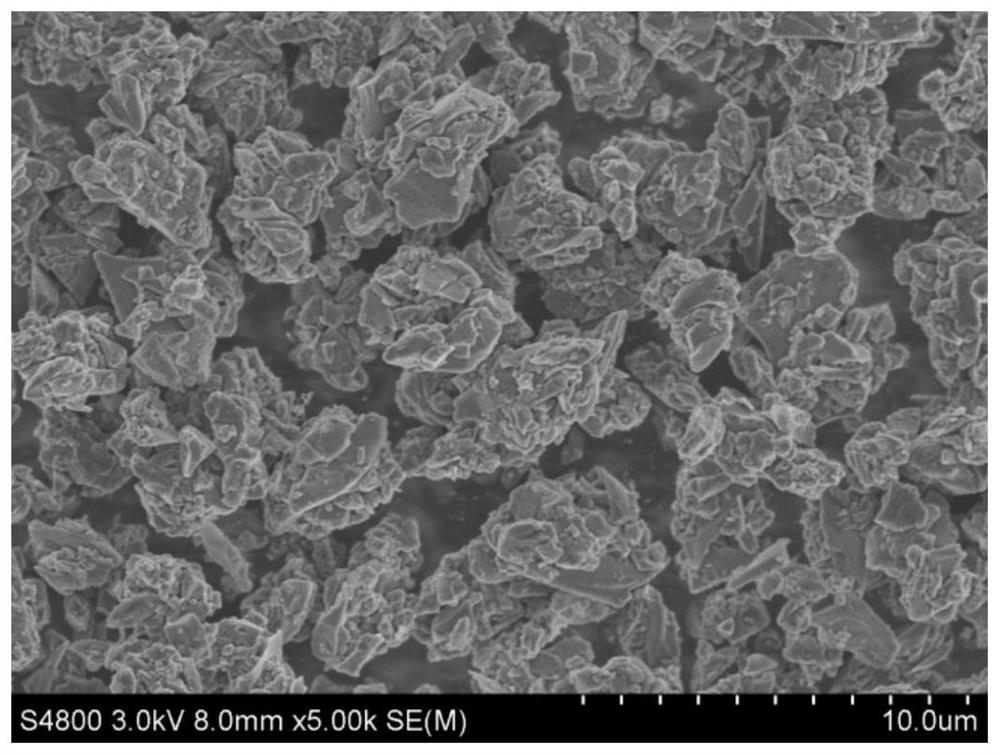

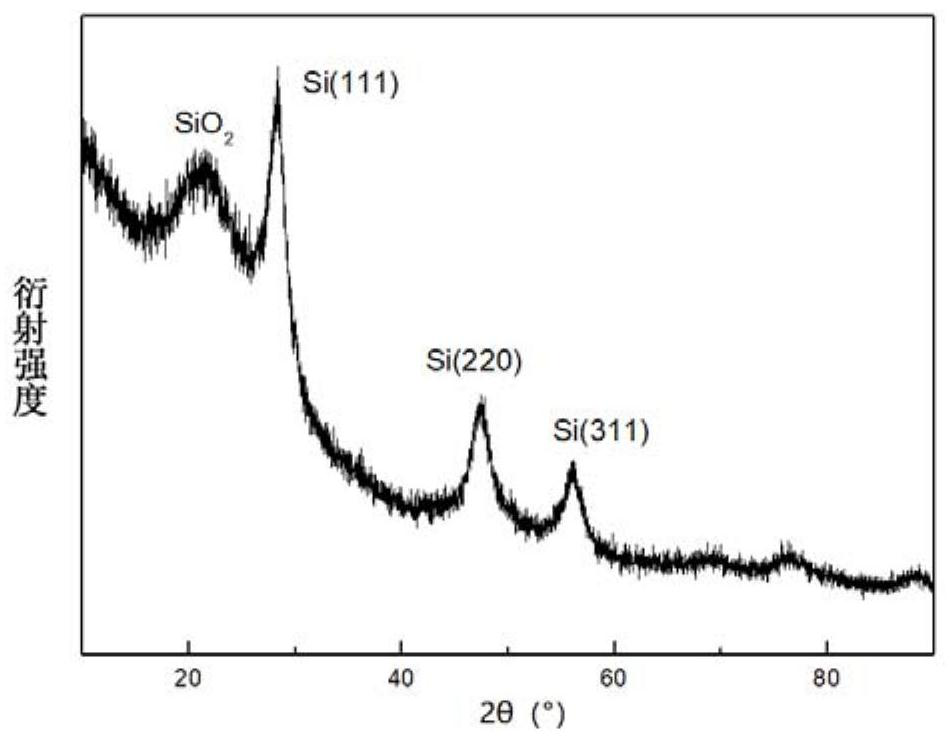

[0096] 1) Mix metal silicon and silicon dioxide at a molar ratio of 1.5:1, and react under the protection of argon at a pressure below 20Pa and a temperature of 1380°C to produce silicon oxide gas, and make this gas flow at 30Pa Under the pressure below, collect the precipitated product on the low temperature zone collector, which is SiOy block, y=0.98;

[0097] 2) Use a universal pulverizer to pulverize the SiOy block obtained in 1) into a powder of about 1 mm, and then pulverize the product with a planetary ball mill to obtain silicon oxide particles with a median particle size of 6 μm; The obtained silicon oxide particles are repeatedly classified to obtain silicon oxide particles in a specific particle size range. The particle volume below μm accounts for 55% of all SiOx particles, D90=3.9μm;

[0098] 3) Put asphalt powder, polyacrylonitrile, Si...

Embodiment 2

[0113] This embodiment prepares silicon oxide / carbon composite negative electrode material according to the following method:

[0114] 1) Mix metal silicon and silicon dioxide at a molar ratio of 1:1, and react under the protection of nitrogen at a pressure below 50Pa and a temperature of 1380°C to generate silicon oxide gas, and keep the gas below 30Pa Under the pressure of , collect the precipitated product on the low temperature zone collector, which is SiOy block, y=1.02;

[0115] 2) Use a mechanical pulverizer to crush the silicon oxide block obtained in 1) into a powder of about 1 mm, and then use a horizontal ball mill to pulverize the product to obtain silicon oxide particles with a median particle size of 7 μm; classify with a multi-stage airflow The machine classifies the obtained particles to obtain silicon oxide particles in a specific particle size range. The specifications are: SiOx particles, the value of x is 0.98, the median D50 of the SiOx particles is 2.8 μm...

Embodiment 3

[0126] This embodiment prepares silicon oxide / carbon composite negative electrode material according to the following method:

[0127] 1) Mix metal silicon and silicon dioxide at a molar ratio of 1:3, and react under the protection of neon gas at a pressure below 100Pa and a temperature of 1500°C to produce silicon oxide gas, and make this gas flow at 50Pa Under the pressure below, collect the precipitated product on the low temperature zone collector, which is SiOy block, y=0.91;

[0128] 2) Use a mechanical pulverizer to crush the silicon oxide block obtained in 1) into a powder of about 1 mm, and then use a horizontal ball mill to pulverize the product to obtain silicon oxide particles with a median particle size of 4.3 μm; The classifier classifies the obtained particles to obtain silicon oxide particles in a specific particle size range. The specifications are: SiOx particles, the value of x is 1.13, the median D50 of the SiOx particles is 0.6 μm, and the particle size is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com