Early strength viscosity reduction type polycarboxylate superplasticizer and preparation method thereof

A technology of polycarboxylic acid and water-reducing agent, which is applied to the early-strength viscosity-reducing polycarboxylate water-reducing agent, in the field of preparation of the early-strength viscosity-reducing polycarboxylate water-reducing agent, can solve the problem of not giving a guiding scheme and other problems, to achieve good early strength and viscosity reduction, good water reduction effect, and construction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

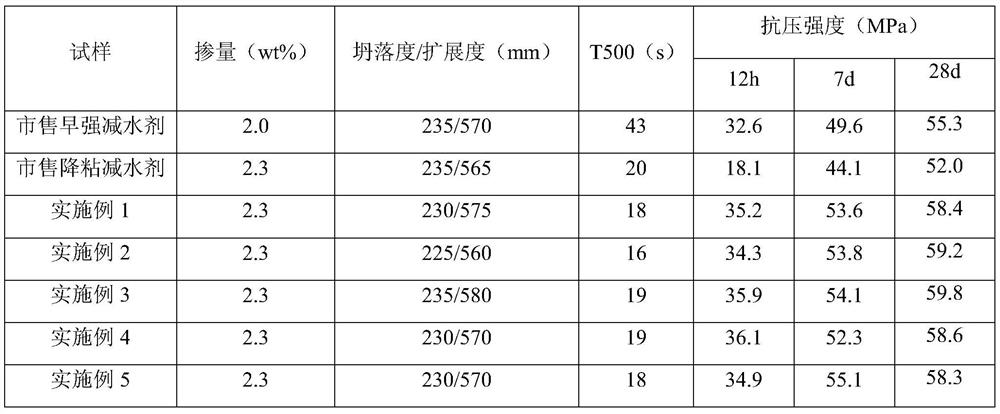

Examples

Embodiment 1

[0017] Embodiment 1: the early-strength viscosity-reducing polycarboxylate superplasticizer of the present invention is made of the following raw materials in parts by weight: 90 parts of polyether monomers, namely methallyl alcohol polyoxyethylene ether ( Molecular weight is 800), 1 part of inorganic early strength component A is calcium nitrate, 2 parts of dispersant are sodium dodecylsulfonate, 100 parts of water, 1.6 parts of inorganic early strength component B are 1.2 parts of magnesium fluorosilicate and Combination of 0.4 parts sodium silicate, drop solution X 1 , drop solution X 2 , 2 parts of initiator are hydrogen peroxide; the preparation method of the above-mentioned early-strength viscosity-reducing polycarboxylate water reducer includes the following process steps: ① according to the above-mentioned parts by weight, first mix 90 parts of polyether monomers, 1 part of inorganic early Add strong component A, 2 parts of dispersant, and 50 parts of water into the r...

Embodiment 2

[0018] Embodiment 2: the early-strength viscosity-reducing polycarboxylate superplasticizer of the present invention is made of the following raw materials in parts by weight: 90 parts of polyether monomers, namely methallyl alcohol polyoxyethylene ether ( Molecular weight is 1000), 2 parts of inorganic early strength component A is calcium bicarbonate, 5 parts of dispersant is sodium dodecylsulfonate, 100 parts of water, 1 part of inorganic early strength component B is 0.6 part of magnesium fluorosilicate and 0.4 parts of lithium silicate, dropwise liquid X 1 , drop solution X 2 , 1.5 parts of initiator i.e. hydrogen peroxide; the preparation method of the above-mentioned early-strength viscosity-reducing polycarboxylate water-reducer comprises the following process steps: ① according to the above-mentioned parts by weight, first mix 90 parts of polyether monomers, 2 parts of inorganic early Add strong component A, 5 parts of dispersant, and 50 parts of water into the react...

Embodiment 3

[0019] Embodiment 3: the early-strength viscosity-reducing polycarboxylate superplasticizer of the present invention is made of the following raw materials in parts by weight: 90 parts of polyether monomers, namely methallyl alcohol polyoxyethylene ether ( Molecular weight is 1200), 5 parts of inorganic early-strength component A is calcium acetate, 5 parts of dispersants are fatty alcohol polyoxyethylene ether sodium sulfate, 100 parts of water, 5 parts of inorganic early-strength component B is potassium silicate, dropwise Liquid X 1 , drop solution X 2 , 3 parts of initiator are hydrogen peroxide; the preparation method of the above-mentioned early-strength viscosity-reducing polycarboxylate superplasticizer includes the following process steps: ① according to the above-mentioned parts by weight, first mix 90 parts of polyether monomers, 5 parts of inorganic early Add strong component A, 5 parts of dispersant, and 50 parts of water into the reactor, and dissolve 5 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com