Preparation method for continuously preparing tert-butylhydrazine hydrochloride

A technology of tert-butylhydrazine and hydrochloride, which is applied in the field of preparation of tert-butylhydrazine hydrochloride, can solve the problems of high VOC emissions, insufficient material contact, low production efficiency, etc., and achieve less discharge of three wastes, production The effect of short cycle time and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

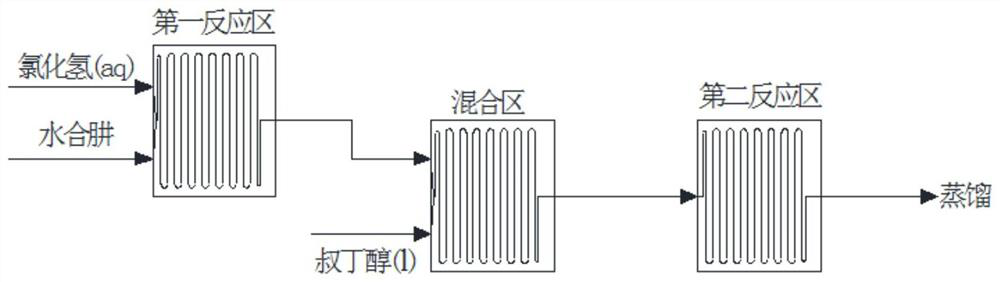

[0026] Present embodiment provides a kind of method utilizing microchannel reactor to continuously synthesize tert-butylhydrazine hydrochloride, concrete implementation is as follows:

[0027] Mass concentration 50% hydrazine hydrate solution is pumped into the first reaction zone of microchannel reactor with 15ml / min flow rate, simultaneously, the hydrochloric acid of mass concentration 20% is pumped into the first reaction zone of microchannel reactor with 3.7ml / min flow rate, the first The temperature of the reaction zone was set at 45°C, and the residence time of the hydrazine hydrate solution and the hydrochloric acid solution was 5.0s.

[0028] The hydrazine hydrochloride solution obtained in the first reaction zone is pumped into the microchannel reactor mixing zone with a flow rate of 15ml / min; tert-butyl alcohol is mixed with 75% aqueous solution, with 18ml / min; the flow rate is pumped into the microchannel reactor mixing zone, and the mixing zone is stably set. Set a...

Embodiment 2

[0031] Mass concentration 70% hydrazine hydrate solution is pumped into the first reaction zone of microchannel reactor with 10ml / min flow rate, simultaneously, the hydrochloric acid of mass concentration 30% is pumped into the first reaction zone of microchannel reactor with 2.0ml / min flow rate, the first The temperature of the reaction zone was set at 50°C, and the residence time of the hydrazine hydrate solution and the hydrochloric acid solution was 4.0s.

[0032] The hydrazine hydrochloride solution obtained in the first reaction zone is pumped into the microchannel reactor mixing zone with a flow rate of 11ml / min; tert-butyl alcohol is mixed with 60% aqueous solution, with 24ml / min; the flow rate is pumped into the microchannel reactor mixing zone, and the mixing zone is stably set. Set at 55°C, the residence time is 6s. The mixed solution after mixing enters the second reaction zone of the microchannel reactor at a flow rate of 17.5 ml / min, and the temperature of the se...

Embodiment 3

[0035] Mass concentration 80% hydrazine hydrate solution is pumped into the first reaction zone of microchannel reactor with 10ml / min flow rate, simultaneously, the hydrochloric acid of mass concentration 30% is pumped into the first reaction zone of microchannel reactor with 1.4ml / min flow rate, the first The temperature of the reaction zone was set at 45°C, and the residence time of the hydrazine hydrate solution and the hydrochloric acid solution was 5.0s.

[0036] The hydrazine hydrochloride solution obtained in the first reaction zone is pumped into the microchannel reactor mixing zone at a flow rate of 11ml / min; tert-butanol is formulated into an 80% aqueous solution at 15.5ml / min; the flow rate is pumped into the microchannel reactor mixing zone, and the mixing zone is stable Set to 60°C and dwell time to 5s. The mixed solution after mixing enters the second reaction zone of the microchannel reactor at a flow rate of 26.5 ml / min, and the temperature of the second reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com