Water-borne epoxy resin, preparation method thereof and water-borne epoxy insulating impregnating varnish

A water-based epoxy resin, insulating impregnating paint technology, applied in epoxy resin coatings, coatings, anti-corrosion coatings, etc., can solve the problems of high odor, poor flexibility, poor coil wettability, etc., to achieve low odor, water resistance and Excellent resistance to salt spray and improved wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

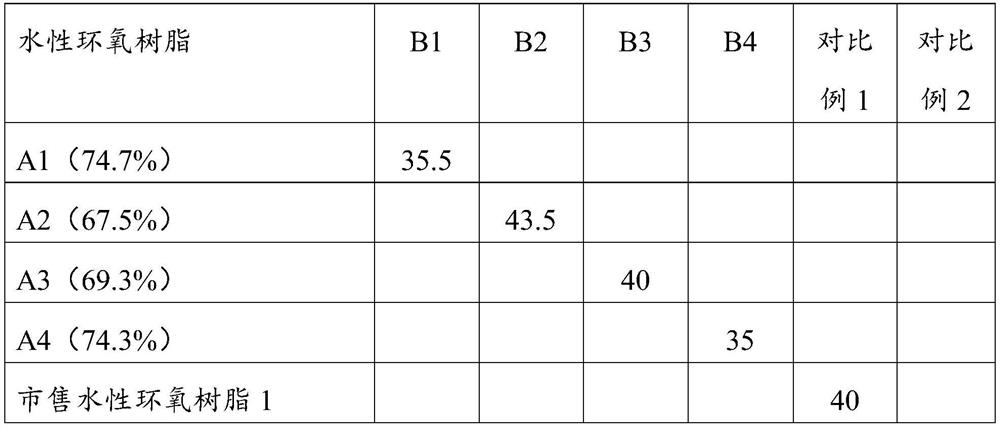

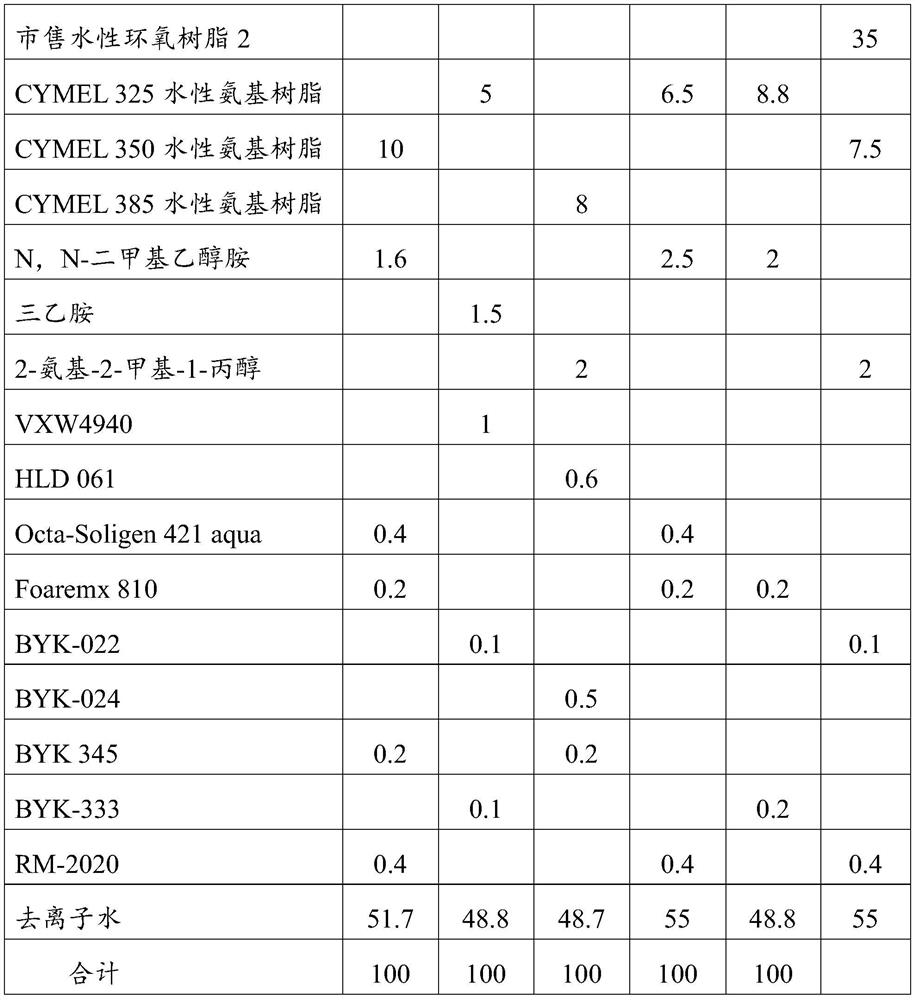

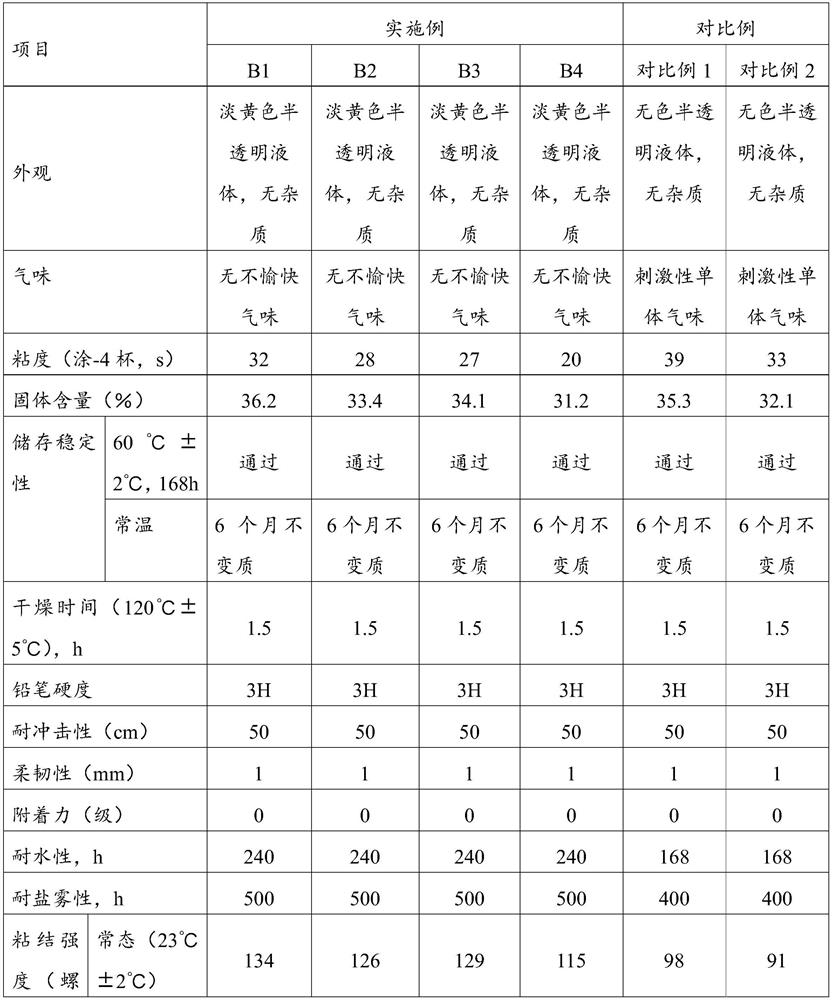

Embodiment 1

[0028] Preparation of waterborne epoxy resin A1

[0029] Add 210 parts of soy oil, 443 parts of NPES-904 epoxy resin and 2 parts of benzyltriethylammonium chloride into the reaction flask, and start to heat up after passing nitrogen gas for 10 minutes; when the temperature rises to 120°C, the materials melt and start stirring; Continue to raise the temperature to 220°C, and keep the reaction at this temperature until the acid value is 10mgKOH / g, then lower the temperature; when the temperature drops to 150°C, add 250 parts of ethylene glycol butyl ether and 95 parts of tung oil anhydride, and keep it at This temperature range was reacted for 5 hours to obtain water-based epoxy resin A1. The waterborne epoxy resin is a transparent viscous liquid with a solid content of 74.7% (weight) and an acid value of 49.9 mgKOH / g (pure solid).

Embodiment 2

[0031] Preparation of Waterborne Epoxy Ester Resin A2

[0032] Add 250 parts of dehydrated ricinoleic acid, 355 parts of F-51 epoxy resin and 2 parts of tetraethylammonium bromide into the reaction flask, and start to heat up after passing nitrogen gas for 15 minutes; when the temperature rises to 80°C, the materials melt and start stirring; Continue to raise the temperature to 220°C, and keep the reaction at this temperature until the acid value is 5mgKOH / g, then lower the temperature; when the temperature drops to 140°C, add 320 parts of dipropylene glycol methyl ether and 73 parts of maleic anhydride, and keep at The temperature range was reacted for 3 hours to obtain the water-based epoxy resin A2. The waterborne epoxy resin is a transparent viscous liquid with a solid content of 67.5% (weight) and an acid value of 49 mgKOH / g (pure solid).

Embodiment 3

[0034] Preparation of Waterborne Epoxy Ester Resin A3

[0035] Add 252 parts of tall oleic acid, 384 parts of NPES-901 epoxy resin and 1 part of zinc oxide into the reaction flask, and start to heat up after passing nitrogen gas for 20 minutes; when the temperature rises to 100°C, the materials melt and start stirring; °C, and keep it at this temperature for reaction, and then lower the temperature until the acid value is 8mgKOH / g; when the temperature drops to 150°C, add 300 parts of diethylene glycol dimethyl ether and 63 parts of trimellitic anhydride, and keep it in this temperature range React for 4 hours to obtain water-based epoxy resin A3. The waterborne epoxy resin is a transparent viscous liquid with a solid content of 69.3% (weight) and an acid value of 44.8mgKOH / g (pure solid).

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com