Preparation method of anti-ultraviolet textile fabric

An anti-ultraviolet, textile fabric technology, applied in the field of textile fabrics, can solve the problems of poor fabric flexibility, lack of antistatic and antibacterial properties, etc., to achieve good washing resistance and durability, significant anti-ultraviolet effect, wearing comfort and Durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

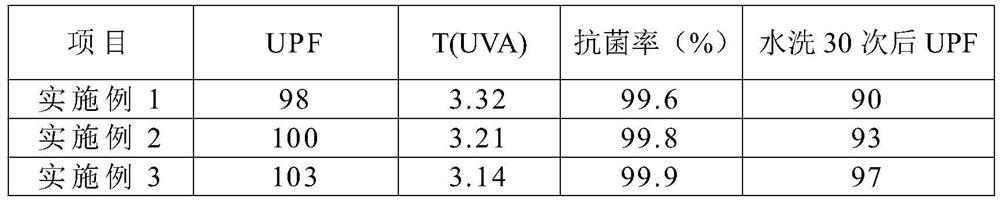

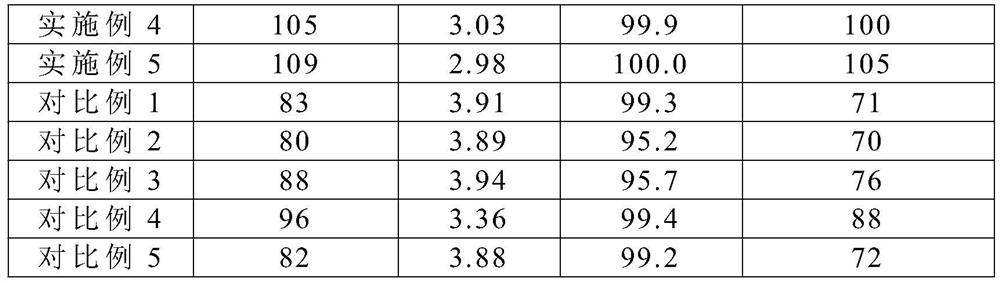

Examples

Embodiment 1

[0032] A preparation method of anti-ultraviolet textile fabric, is characterized in that, comprises the following steps:

[0033]Step S1, preparation of anti-ultraviolet functional copolymer: 2-trimethylsiloxy-4-propenyloxybenzophenone, allyl salicylate, 2-vinylpyrazine, 1-(trifluoroacetic acid) Methyl)vinyl ester, dimethylaminoethyl acrylate and initiator were added to the high boiling point solvent, stirred and reacted at 65°C for 3 hours in a nitrogen atmosphere, and then precipitated in water, and the precipitated polymer was treated with ethanol Washed 3 times, and finally dried to constant weight at 85°C in a vacuum drying oven to obtain an anti-ultraviolet functional copolymer;

[0034] Step S2, epoxy-modified anti-ultraviolet functional copolymer: add the anti-ultraviolet functional copolymer and epichlorohydrin prepared in step S1 into dimethyl sulfoxide, stir and react at 40° C. for 6 hours, and then Precipitate in water, wash the precipitated polymer with ethanol f...

Embodiment 2

[0045] A preparation method of anti-ultraviolet textile fabric, is characterized in that, comprises the following steps:

[0046] Step S1, preparation of anti-ultraviolet functional copolymer: 2-trimethylsiloxy-4-propenyloxybenzophenone, allyl salicylate, 2-vinylpyrazine, 1-(trifluoroacetic acid) Methyl)vinyl ester, dimethylaminoethyl acrylate and initiator were added to the high boiling point solvent, and the reaction was stirred at 67°C for 3.5 hours in an inert gas atmosphere, and then precipitated in water, and the precipitated polymer was used Washed with ethanol for 4 times, and finally dried to constant weight at 87°C in a vacuum drying oven to obtain an anti-ultraviolet functional copolymer;

[0047] Step S2, epoxy modified anti-ultraviolet functional copolymer: add the anti-ultraviolet functional copolymer and epichlorohydrin prepared in step S1 into dimethyl sulfoxide, stir and react at 45° C. for 6.5 hours, and then Precipitate in water, wash the precipitated polym...

Embodiment 3

[0058] A preparation method of anti-ultraviolet textile fabric, is characterized in that, comprises the following steps:

[0059] Step S1, preparation of anti-ultraviolet functional copolymer: 2-trimethylsiloxy-4-propenyloxybenzophenone, allyl salicylate, 2-vinylpyrazine, 1-(trifluoroacetic acid) Methyl)vinyl ester, dimethylaminoethyl acrylate and initiator were added to the high boiling point solvent, stirred and reacted at 70°C for 4 hours in an inert gas atmosphere, and then precipitated in water, and the precipitated polymer was used Washed with ethanol for 5 times, and finally dried to constant weight at 90°C in a vacuum drying oven to obtain an anti-ultraviolet functional copolymer;

[0060] Step S2, epoxy-modified anti-ultraviolet functional copolymer: add the anti-ultraviolet functional copolymer and epichlorohydrin prepared in step S1 into dimethyl sulfoxide, stir and react at 50° C. for 7 hours, and then Precipitate in water, wash the precipitated polymer with ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com