A kind of production method of copper ion antibacterial yarn

A production method and technology of copper ions, applied in yarn, biochemical fiber processing, textile material processing and other directions, can solve problems such as large health hazards, safety hazards, human body and environment safety hazards, etc., to improve washability, The effect of improving mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

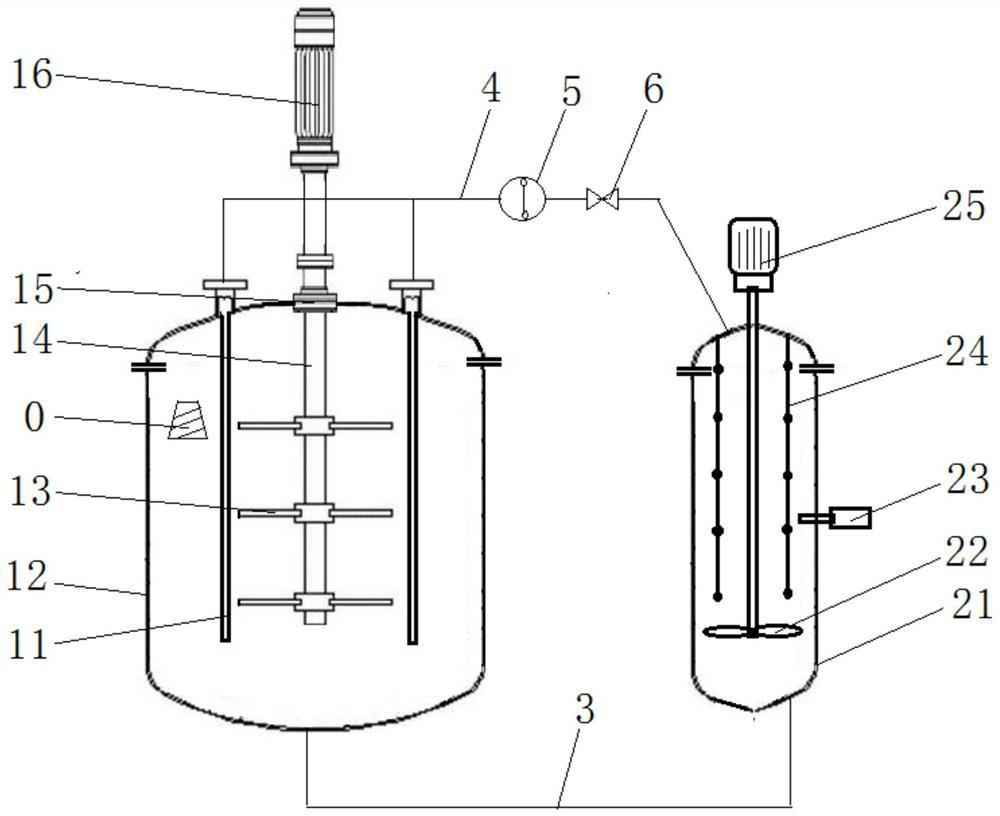

[0029] The specific technical solutions of the present invention are further described in the accompanying drawings of the structural description below.

[0030] A kind of production method of copper ion antibacterial yarn of the present invention, comprises the following steps:

[0031] S1) Alkali activation of cellulose fibers

[0032] The cellulose fibers include one or more of cotton, viscose, tencel, hemp and the like.

[0033] S11) Place the cellulose fiber O in the main vat, add sodium hydroxide or potassium hydroxide solution for cooking.

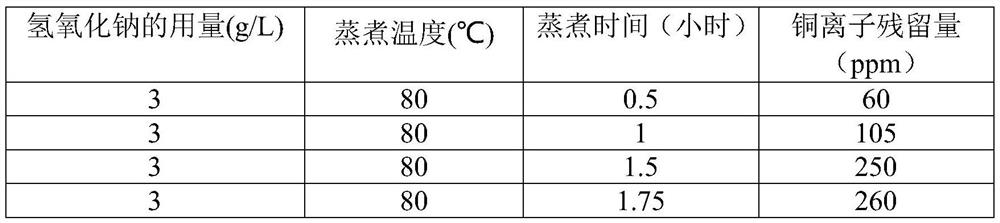

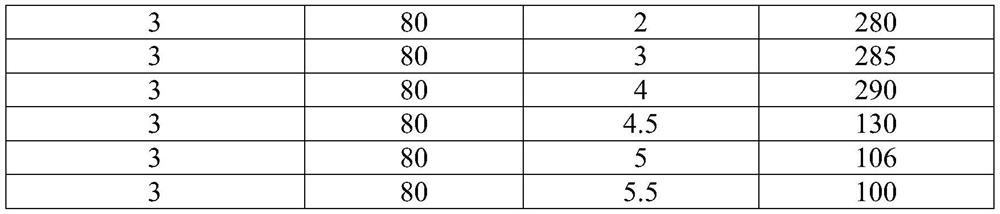

[0034] In order to obtain the optimal parameters for alkali activation of cellulose fibers, a series of comparative experiments were used to analyze them. Through experiments, it is found that the cooking time is 1.5-4 hours, and the copper ion antibacterial yarn has better copper ion washing resistance, which can bring the graft fastness of copper ion and fiber. As shown in Table 1 below.

[0035] Table 1

[0036]

[0037] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com