Gallium oxide-based heterojunction integrated photoelectric chip, remote ultraviolet array monitor and manufacturing method of remote ultraviolet array monitor

A gallium oxide-based, optoelectronic chip technology, applied in photometry, measurement of ultraviolet rays, circuits, etc. using electric radiation detectors, can solve the attenuation of sterilization effects, affect the application effect, and it is difficult to detect the intensity of ultraviolet radiation and the range of wavelengths, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

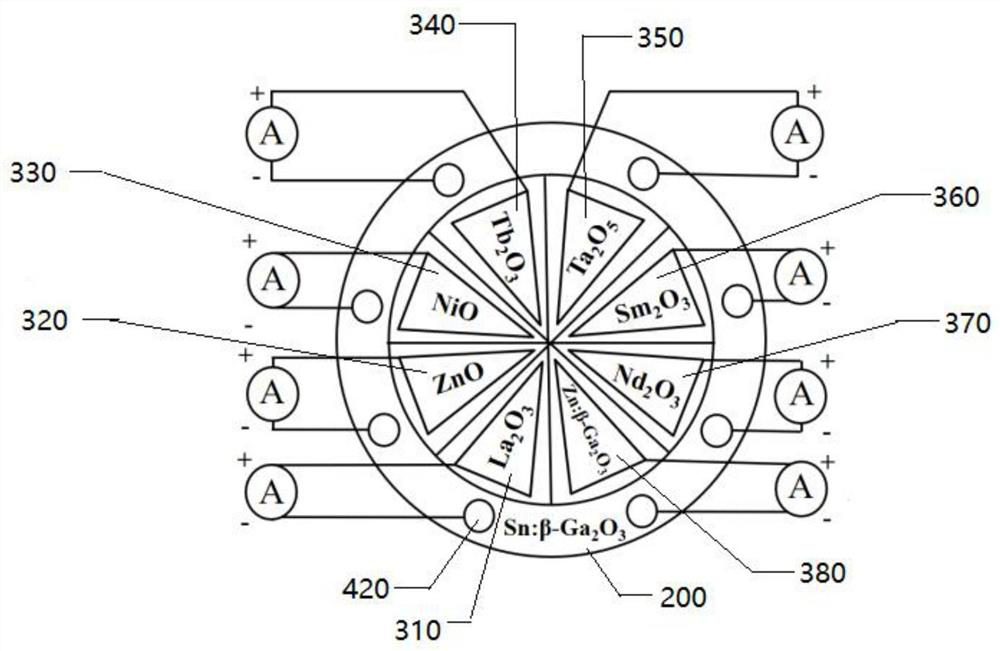

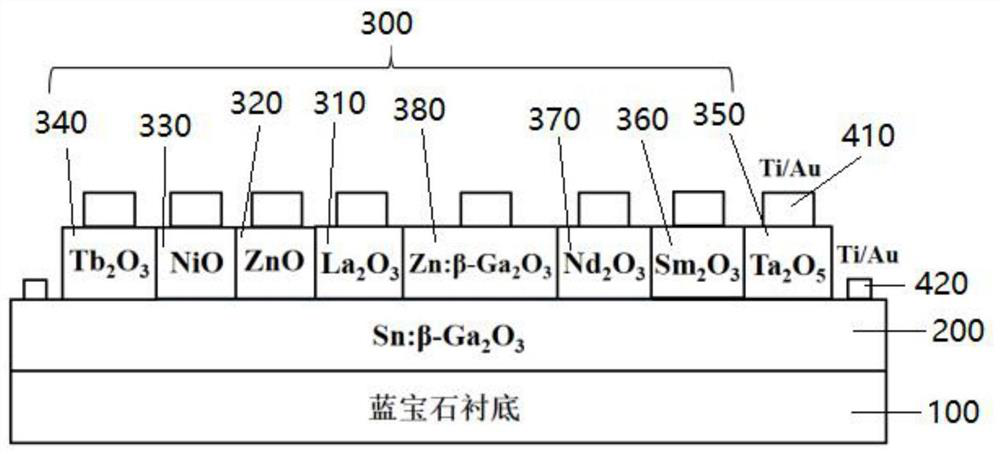

[0035] like Figure 1-2 As shown, a wide-ranging gallium oxide-based heterojunction integrated optoelectronic chip includes a sapphire single crystal substrate 100, Sn:β-Ga 2 o 3 Circular film 200 and composite film 300; Wherein said composite film 300 comprises La located on the same plane and arranged in a circle 2 o 3 Thin film 310, ZnO thin film 320, NiO thin film 330, Tb 2 o 3 Film 340, Ta 2 o 5 Film 350, Sm 2 o 3 Film 360, Nd 2 o 3 Thin film 370 and Zn:β-Ga 2 o 3 Thin film 380, adopted in Sn:β-Ga 2 o 3 A composite film composed of a plurality of films is formed on the circular film 200, which can form a La 2 o 3 / Sn:β-Ga 2 o 3 、ZnO / Sn:β-Ga 2 o 3 、NiO / Sn:β-Ga 2 o 3 , Tb 2 o 3 / Sn:β-Ga 2 o 3 、 Ta 2 o 5 / Sn:β-Ga 2 o 3 、Sm 2 o 3 / Sn:β-Ga 2 o 3 、Nd 2 o 3 / Sn:β-Ga 2 o 3 and Zn:β-Ga 2 o 3 / Sn:β-Ga 2 o 3 Heterojunction structure, in which ZnO, NiO, Tb 2 o 3 、 Ta 2 o 5 、Sm 2 o 3 , Nd 2 o 3 、Zn:β-Ga 2 o 3 and La 2 o 3 The forbid...

Embodiment 2

[0039] A method for manufacturing a UV-C / B / A remote ultraviolet array monitor with continuously adjustable wavelength has the following steps:

[0040] (1) Preparation of gallium oxide-based heterojunction integrated optoelectronic chips:

[0041] Put the c-plane sapphire circular single crystal substrate into V(HF):V(H 2 o 2 )=1:5 solution soaked to remove the natural oxide layer, then ultrasonically cleaned with acetone, ethanol and deionized water, and vacuum-dried; the 99.99% pure Ga 2 o 3 , La 2 o 3 , ZnO, NiO, Tb 2 o 3 、 Ta 2 o 5 、Sm 2 o 3 and Nd 2 o 3 The targets are respectively placed on the target stage of the multi-target laser pulse deposition system. 2 o 3 Place a Sn metal ring around the glow circle of the target, fix the c-plane sapphire circular single crystal substrate after the above treatment on the sample holder, put it into the vacuum chamber, each target and the c-plane sapphire circular single crystal substrate The distance between them is...

Embodiment 3

[0058] Step (2) is identical with embodiment 2. In step (1), put the c-plane sapphire circular single crystal substrate into V(HF):V(H 2 o 2 )=1:5 solution soaked to remove the natural oxide layer, then ultrasonically cleaned with acetone, ethanol and deionized water, and vacuum-dried; the 99.99% pure Ga 2 o 3 , La 2 o 3 , ZnO, NiO, Tb 2 o 3 、 Ta 2 o 5 、Sm 2 o 3 and Nd 2 o 3 The targets are respectively placed on the target stage of the multi-target laser pulse deposition system. 2 o 3 Place a Sn metal ring around the glow circle of the target, fix the above-mentioned c-plane sapphire circular single crystal substrate on the sample holder, put it into the vacuum chamber, each target and the c-plane sapphire circular single crystal substrate The distance between them is 5 cm; the cavity is evacuated first, argon gas is introduced, the pressure in the vacuum cavity is adjusted, the sapphire single crystal substrate is heated, and the Sn-doped Ga 2 o 3 thin film, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com