Method for preparing piperacillin sodium and tazobactam sodium freeze-dried powder by microreactor

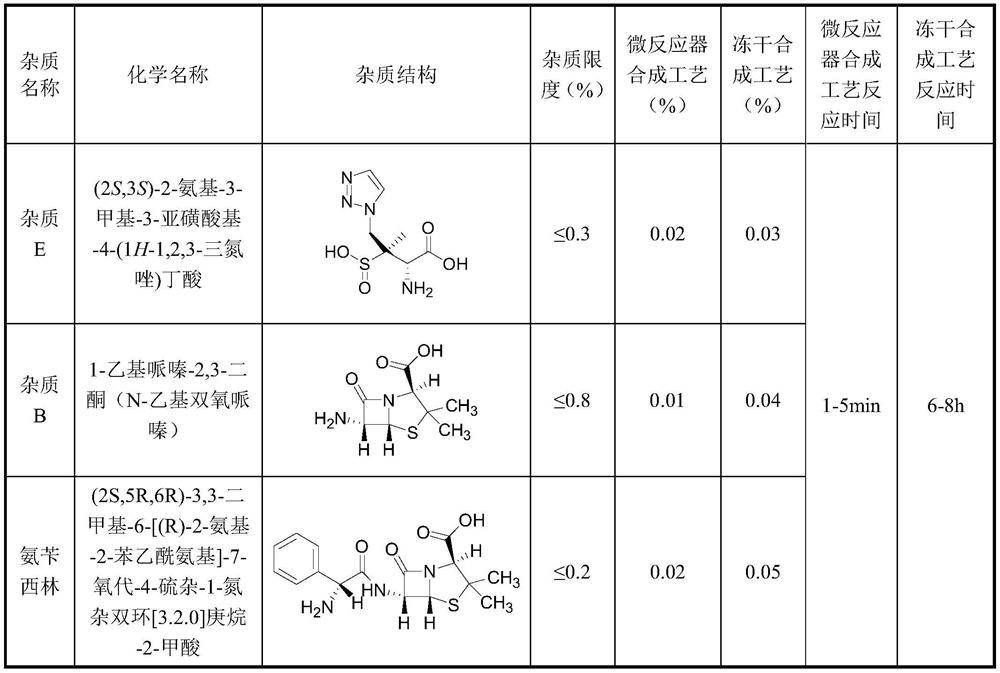

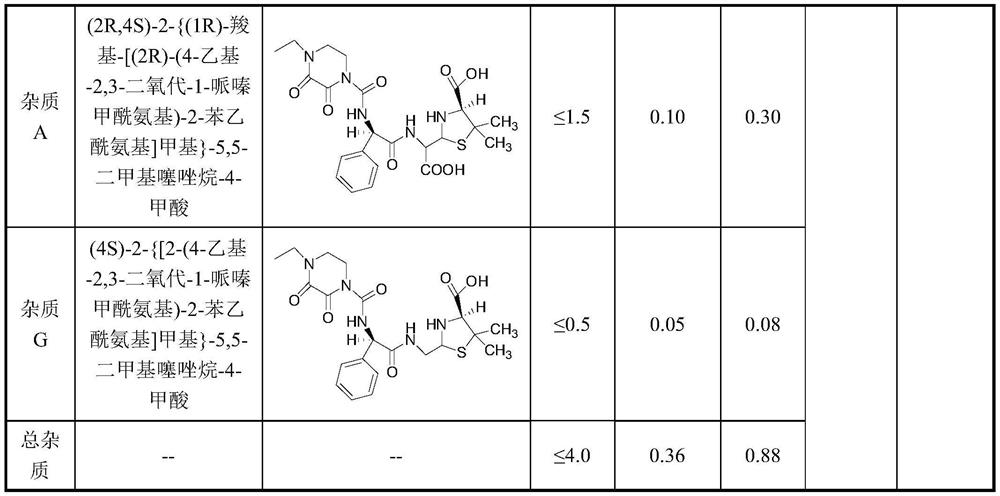

A technology of piperacillin sodium and tazobactam sodium, which is applied in the field of medicine, can solve the problems of high local alkalinity, slow feed-liquid reaction, and increased impurities in finished products, and achieve short reaction cycle, short residence time, and less degraded impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

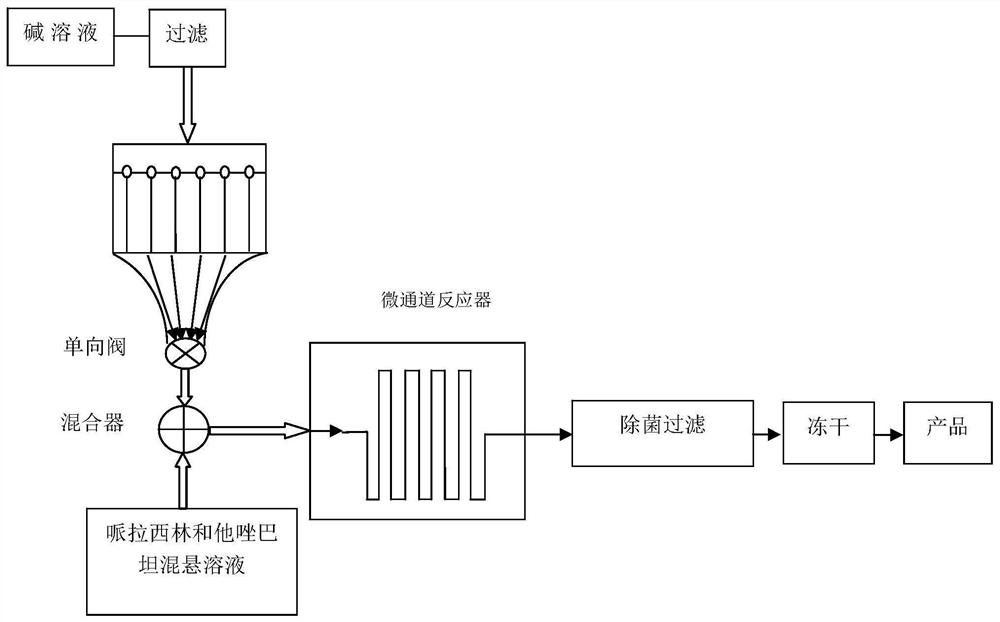

Method used

Image

Examples

Embodiment 1

[0031] (1) Weigh 7.3g of sodium hydroxide and add it to 120g of water for injection, stir and dissolve, cool down to 5-10°C, and set aside;

[0032] (2) Weigh 80.0 g of piperacillin and 10.0 g of tazobactam, add 150 g of water for injection and stir to obtain piperacillin-tazobactam suspension, cool to 5-10°C, and set aside;

[0033] (3) Controlling the flow rate of sodium hydroxide feed liquid (filtered in advance) is 53g / min, and the flow rate of piperacillin and tazobactam suspension solution is 100g / min, and the two feed liquids are passed through the mixer to the micro-reaction channel to control the reaction The temperature is 5-10°C, the reaction is 2.4min, and the piperacillin sodium-tazobactam sodium solution is obtained, and the pH of the feed liquid is 6.2; the feed liquid is directly filled and freeze-dried through a sterile filtration system to obtain piperacillin sodium-tazobactam sodium Sodium freeze-dried powder 86.5g, yield 95.05%, purity 99.52%.

Embodiment 2

[0035] (1) Weigh 15.5g of sodium bicarbonate and add it to 112.5g of water for injection, stir and dissolve, cool down to 5-10°C, and set aside;

[0036] (2) Weigh 80.0 g of piperacillin and 10.0 g of tazobactam, add 150 g of water for injection and stir to obtain piperacillin-tazobactam suspension, cool to 5-10°C, and set aside;

[0037] (3) control the flow rate of sodium bicarbonate feed liquid (filtered in advance) to be 64g / min, and the flow rate of piperacillin and tazobactam suspension solution to be 120g / min, and the two feed liquids are passed through the mixer to the micro-reaction channel to control the reaction The temperature is 5-10°C, and the piperacillin sodium-tazobactam sodium solution is obtained after 2 minutes of reaction. The pH of the feed solution is 6.3; the carbon dioxide generated during the reaction does not need to be removed by vacuuming. Discharged into the air; the feed liquid was directly filled and freeze-dried through a sterile filtration sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com