Preparation method of waterproof gas-permeable film for lithium-air battery

A technology of waterproof breathable film and film former, which is applied in the direction of battery pack components, fuel cell half-cells and secondary battery-type half-cells, circuits, etc., which can solve the problem of affecting battery discharge capacity, service life and safety , can not fully represent the application of lithium-air batteries, the increase of battery impedance and other problems, to achieve the effect of good waterproof and breathable performance, moderate strength, and satisfying the amount of oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

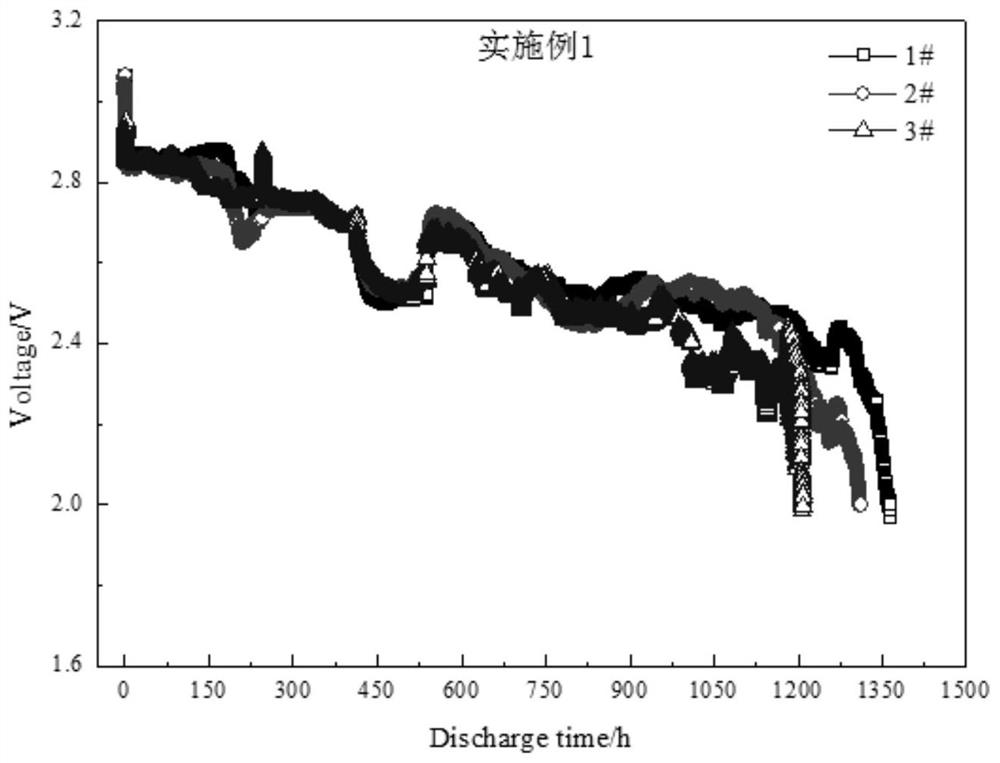

Embodiment 1

[0035] Weigh 40g of white oil and 5g of high-density polyethylene, put them into a beaker, put the beaker into an oil bath preheated at 150°C, and stir magnetically until the high-density polyethylene is melted to obtain a film-forming slurry. Pour the film-forming slurry into the film-forming device, and obtain an oil-containing film after cooling. Put the oil-containing film into the dichloromethane extractant, and extract the white oil in it after repeated extractions. The extracted film is placed in a drying oven at a temperature of 30°C, and the extractant on the surface and inside of the film is volatilized and removed to obtain a waterproof and breathable film.

Embodiment 2

[0037] Weigh 40g of white oil and 5g of linear low-density polyethylene, put them into a beaker, put the beaker into an oil bath preheated at 130°C, and stir magnetically until the linear low-density polyethylene melts to obtain a film-forming slurry. Pour the film-forming slurry into the film-forming device, and obtain an oil-containing film after cooling. Put the oil-containing film into the dichloromethane extractant, and extract the white oil in it after repeated extractions. The extracted film is placed in a drying oven at a temperature of 30°C, and the extractant on the surface and inside of the film is volatilized and removed to obtain a waterproof and breathable film.

Embodiment 3

[0039] Weigh 40g of white oil and 5g of amorphous α-olefin copolymer, put them into a beaker, put the beaker into an oil bath preheated at 170°C, and stir magnetically until the amorphous α-olefin copolymer melts to obtain Film-forming slurry. Pour the film-forming slurry into the film-forming device, and obtain an oil-containing film after cooling. Put the oil-containing film into the dichloromethane extractant, and extract the white oil in it after repeated extractions. The extracted film is placed in a drying oven at a temperature of 30°C, and the extractant on the surface and inside of the film is volatilized and removed to obtain a waterproof and breathable film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com