High-compressive-strength low-density material and application thereof

A low-density material, compressive strength technology, applied in the direction of additive processing, single-component polyester rayon, single-component polyamide rayon, etc., can solve the problem of only 30KPa compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Control the temperature in the reaction kettle to minus 30°C, add 90 parts of concentrated sulfuric acid with a mass fraction of 98% into the reaction kettle, add 1 part of flake graphite, 10 parts of hydrogen peroxide, and 1 part of potassium permanganate in turn under stirring, and react for 2 hours to obtain Sulfur oxide graphite; at room temperature, the sulfur-containing graphite oxide is added to a mixed solution of water and ethanol, stirred and dispersed evenly to obtain a sulfur-containing graphite oxide dispersion; wherein, the volume fraction of water in the mixed solution of water and ethanol is 20 %;

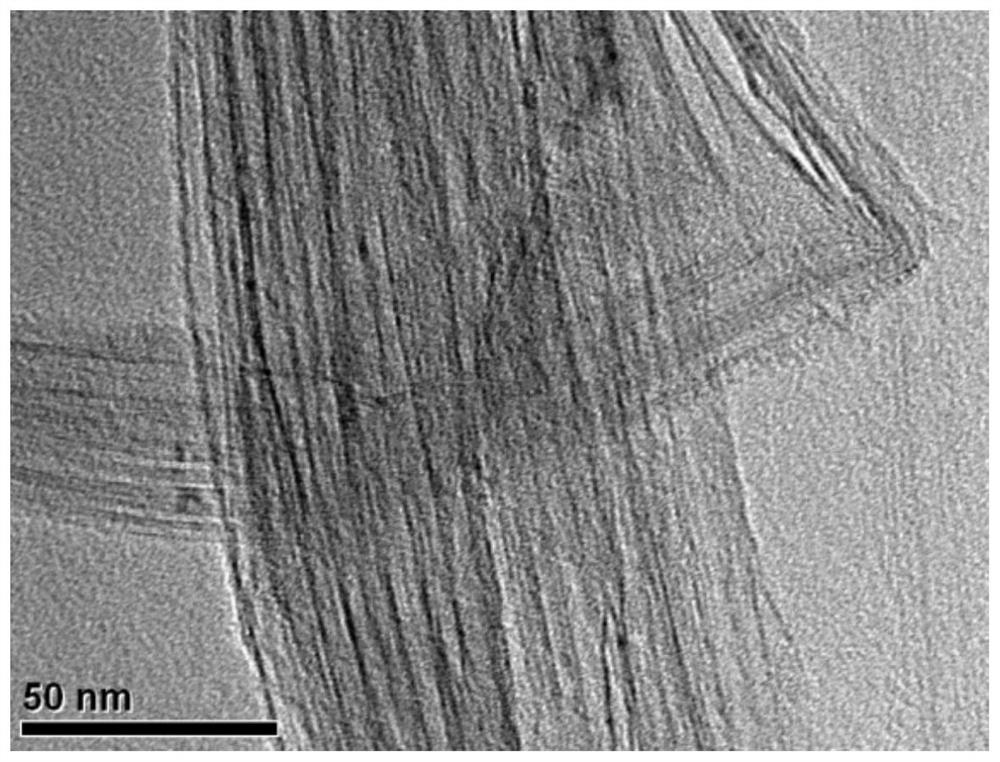

[0030] Under a protective gas atmosphere, add 3 parts of ferrocene to 100 parts of the sulfur-containing graphite oxide dispersion, control the reaction temperature to 1200 ° C, collect gasification products, and obtain a carbon nanotube aerosol; the density of the aerosol is 0.83g / cm 3 ; The TEM result of described carbon nanotube aerosol is as figure 1 As...

Embodiment 2

[0034] Control the temperature in the reaction kettle to minus 20°C, add 70 parts of concentrated sulfuric acid with a mass fraction of 98% into the reaction kettle, add 1 part of flake graphite, 30 parts of hydrogen peroxide, and 1 part of potassium permanganate successively under stirring, and react for 2 hours to obtain Sulfur oxide graphite; at room temperature, adding the sulfur-containing graphite oxide into the mixed solution of water and methanol, stirring and dispersing evenly to obtain a sulfur-containing graphite oxide dispersion; wherein, the volume fraction of water in the mixed solution of water and methanol is 10 %;

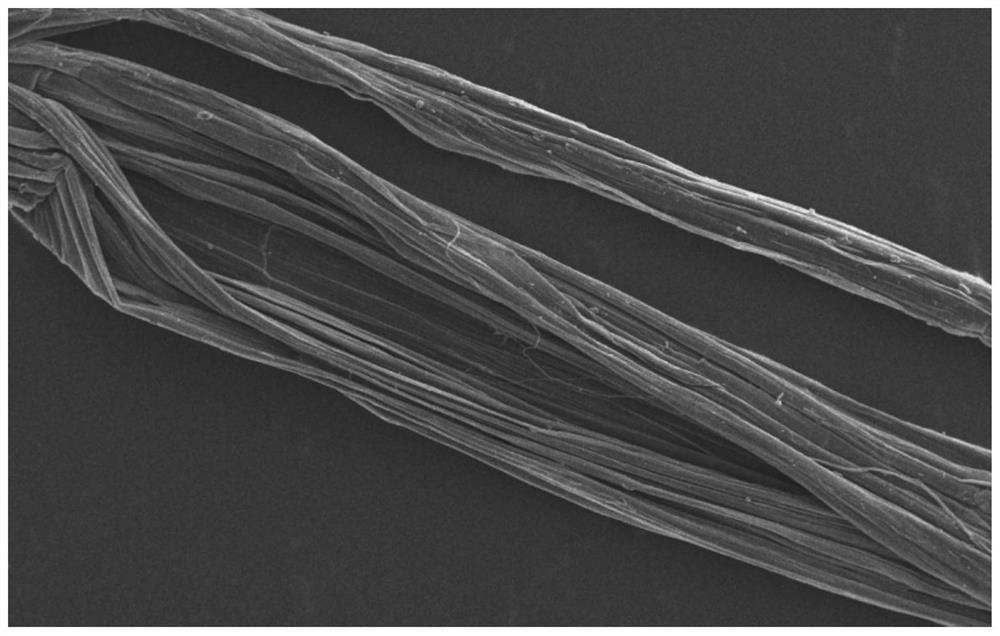

[0035] Under a protective gas atmosphere, add 5 parts of ferrocene to 100 parts of the sulfur-containing graphite oxide dispersion, control the reaction temperature to be 1100 ° C, collect gasification products, and obtain carbon nanotube aerosol; the density of the aerosol is 0.84g / cm 3 ; The TEM results of the carbon nanotube aerosol show that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com