Resin for metal coiled material and preparation method thereof

A metal coil and resin technology, applied in the field of resin for metal coils and its preparation, can solve the problems of inconvenient use of metal coils, insufficient strength and aging resistance, and high requirements for production workers, so as to improve the anti-ultraviolet performance , Increase water resistance and anti-fouling performance, improve the effect of low temperature curing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

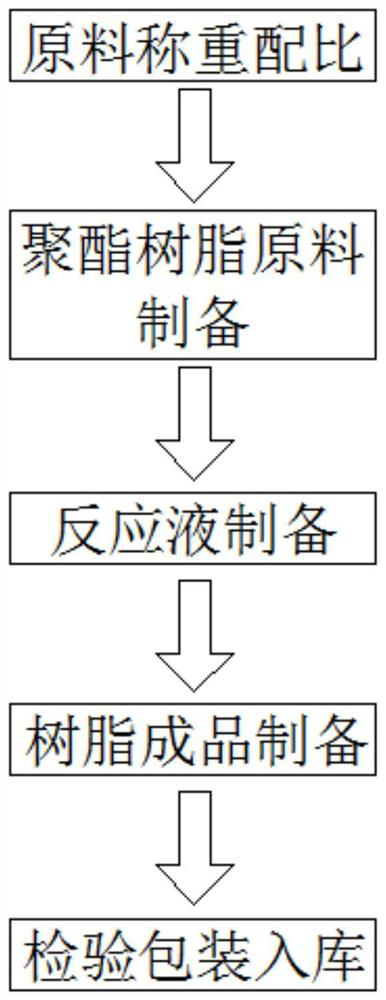

[0026] according to figure 1 As shown, this embodiment provides a resin for metal coils and a preparation method thereof, including the following raw materials in parts by weight: 35 parts of unsaturated polyester resin, 10 parts of initiator, 10 parts of crosslinking agent, 10 parts of catalyst, pigment 15 parts of filler, 5 parts of isophthalic acid, 10 parts of surface hydrophobic agent, 10 parts of ethylene glycol, 10 parts of waste PCB powder, 10 parts of carbolic acid, 5 parts of methylene oxide, 3 parts of pH regulator, 8 parts of penetrating agent , 10 parts of diluents, the unsaturated polyester resin is a linear polymer, mainly formed by polycondensation of saturated dibasic acids, unsaturated dibasic acids and dibasic alcohols, the initiator is a redox initiator, and the The crosslinking agent is dicumyl peroxide, the catalyst is a heterogeneous catalyst, the pigment and filler are mixed with high temperature resistant functional pigments and conductive functional p...

Embodiment 2

[0039] according to figure 1 As shown, this embodiment provides a resin for metal coils and a preparation method thereof, including the following raw materials in parts by weight: 45 parts of unsaturated polyester resin, 15 parts of initiator, 13 parts of crosslinking agent, 14 parts of catalyst, pigment 20 parts of filler, 10 parts of isophthalic acid, 14 parts of surface hydrophobic agent, 13 parts of ethylene glycol, 15 parts of waste PCB powder, 15 parts of carbolic acid, 10 parts of methylene oxide, 5 parts of pH regulator, 10 parts of penetrant part, 12 parts of diluent, the unsaturated polyester resin is a linear polymer, mainly formed by polycondensation of saturated dibasic acid, unsaturated dibasic acid and dibasic alcohol, and the initiator is a redox initiator, so The crosslinking agent is dicumyl peroxide, the catalyst is a heterogeneous catalyst, the pigment and filler are mixed with high temperature resistant functional pigments and conductive functional pigment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com