A kind of preparation method of oxide dispersion strengthened al-mg-si aluminum alloy

An al-mg-si and dispersion strengthening technology, applied in the direction of additive processing, etc., can solve the problems of unsatisfactory requirements, irregular shape, and reduced alloy performance, etc., and achieve strong designability, small particle size, and high density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

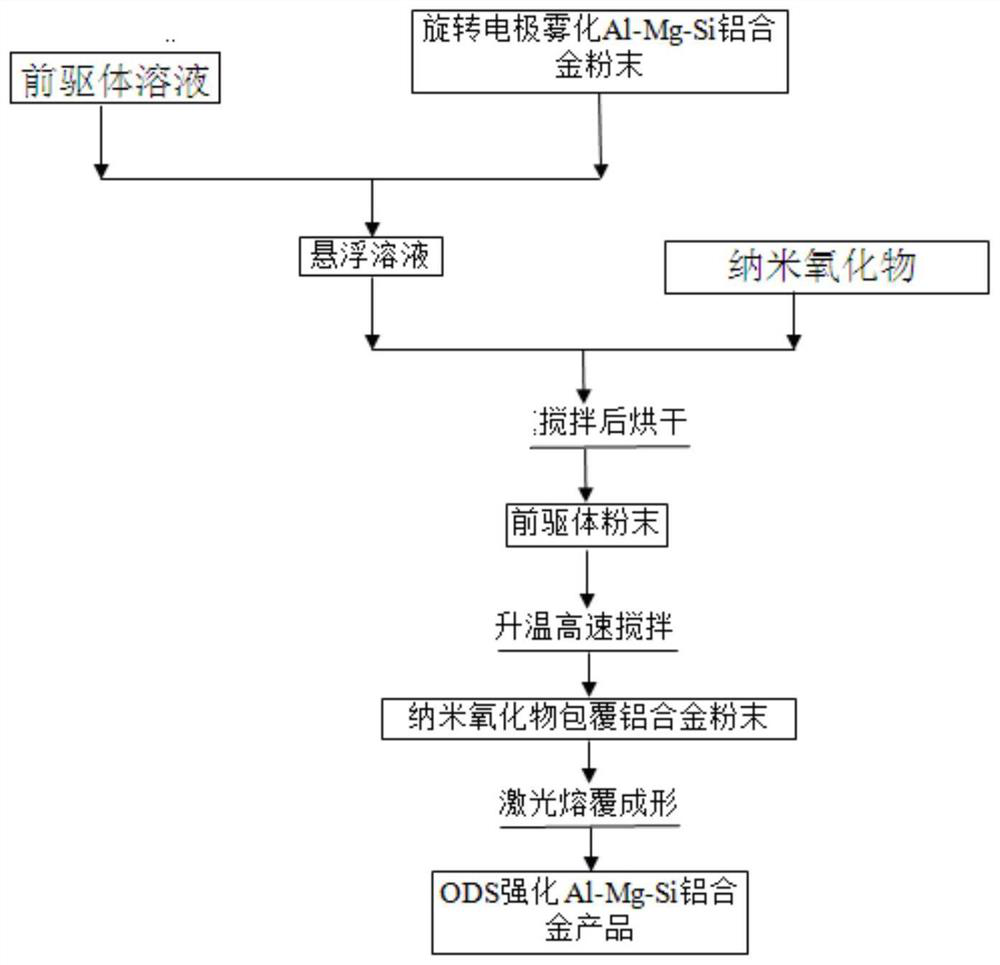

Image

Examples

Embodiment 1

[0053] Element

[0054] Al-0.75wt.%Mg-0.5wt.%Si-0.2wt.%Fe-0.08wt.%Cu-0.1wt.%Mn-0.08wt.%Ti-0.11wt.%Zn-0.5wt.%La 2 o 3 Preparation of aluminum alloy

[0055] Will be composed as

[0056] Rotating electrode atomized powder of Al-0.75wt.%Mg-0.5wt.%Si-0.2wt.%Fe-0.08wt.%Cu-0.1wt.%Mn-0.08wt.%Ti-0.11wt.%Zn and Nano La 2 o 3 The powder is weighed with a mass ratio of 99.5:0.5 for future use. The weighed mist of Al-0.75wt.%Mg-0.5wt.%Si-0.2wt.%Fe-0.08wt.%Cu-0.1wt.%Mn-0.08wt.%Ti-0.11wt.%Zn Dissolve the powder in 8g·L -1 Polydiallyldimethylammonium chloride solution, soaked for 30 minutes, and then the nano-La 2 o 3 After the powder was added into the solution and stirred for 2 hours, the solution was dried to obtain a powder precursor. The powder precursor was stirred for 2 hours in an argon atmosphere at a temperature of 100° C. and a stirring propeller rotating at a speed of 25,000 rpm to obtain nano-oxide-coated aluminum alloy powder. Finally, aluminum alloy powder was wrapp...

Embodiment 2

[0058] Element

[0059] Al-0.45wt.%Mg-0.25wt.%Si-0.2wt.%Fe-0.05wt.%Cu-0.08wt.%Mn-0.05wt.%Ti-0.1wt.%Zn-1wt.%La 2 o 3 Preparation of aluminum alloy

[0060] Will be composed as

[0061] Al-0.45wt.%Mg-0.25wt.%Si-0.2wt.%Fe-0.05wt.%Cu-0.08wt.%Mn-0.05wt.%Ti-0.1wt.%Zn rotating electrode atomized powder and Nano La 2 o 3 The powder is weighed with a mass ratio of 99:1 for future use. The weighed mist of Al-0.45wt.%Mg-0.25wt.%Si-0.2wt.%Fe-0.05wt.%Cu-0.08wt.%Mn-0.05wt.%Ti-0.1wt.%Zn Dissolve the powder in 6g·L -1 Polydiallyldimethylammonium chloride solution, soaked for 20 minutes, and then the nano-La 2 o 3 The powder was added into the solution and stirred for 1.5 hours, and then the solution was dried to obtain a powder precursor. The powder precursor was stirred for 2 hours in an argon atmosphere at a temperature of 90° C. and a stirring propeller rotating at a speed of 20,000 rpm to obtain nano-oxide-coated aluminum alloy powder. Finally, the aluminum alloy powder was wra...

Embodiment 3

[0063] Element

[0064] Al-0.55wt.%Mg-0.45wt.%Si-0.15wt.%Fe-0.05wt.%Cu-0.07wt.%Mn-0.06wt.%Ti-0.08wt.%Zn-0.6wt.%Y 2 o 3 Preparation of aluminum alloy

[0065] Will be composed as

[0066] Al-0.55wt.%Mg-0.45wt.%Si-0.15wt.%Fe-0.05wt.%Cu-0.07wt.%Mn-0.06wt.%Ti-0.08wt.%Zn rotating electrode atomized powder and Nano Y 2 o 3 The powder is weighed with a mass ratio of 99.4:0.6 for future use. The weighed mist of Al-0.55wt.%Mg-0.45wt.%Si-0.15wt.%Fe-0.05wt.%Cu-0.07wt.%Mn-0.06wt.%Ti-0.08wt.%Zn Dissolve the powder in 4g·L -1 cysteine solution, soaked for 15 minutes, and then the nano-Y 2 o 3 After the powder was added into the solution and stirred for 1 hour, the solution was dried to obtain a powder precursor. The powder precursor was stirred for 2 hours in an argon atmosphere at a temperature of 110° C. and a stirring propeller rotating at a speed of 20,000 rpm to obtain nano-oxide-coated aluminum alloy powder. Finally, the aluminum alloy powder was wrapped with nano-oxide f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com