Preparation method of two-dimensional woven environment-friendly and high-strength wood-based composite material

A composite material, green and environmentally friendly technology, applied in impregnated wood, wood impregnation, wood processing equipment, etc., can solve the problems of large differences in vertical and horizontal mechanical properties, and achieve the effects of improved mechanical properties, high mechanical properties of materials, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention is based on a preparation method of a two-dimensional braided high-strength wood-based composite material, comprising the following steps:

[0039] (1) Basic unit veneer preparation: the solid wood is made into a veneer by the rotary cutting process, the veneer is partially de-lignified, and then the de-lignified veneer is aligned in the same direction to form a blank, and put into the mold. High-temperature hot pressing makes the slab dense; the cooling press takes out the slab, separates each layer of veneer, and then cuts it into long strips of wood suitable for weaving, that is, the basic veneer.

[0040] The partial lignin removal is to remove 0-50% of the original lignin content; the veneers are aligned in the same direction to form a blank, and the veneers are required to contain water, and the moisture content is 0-50%; High temperature hot pressing, the temperature range is 80-200 ° C; the denseness mentioned means that after compression, ...

Embodiment 1

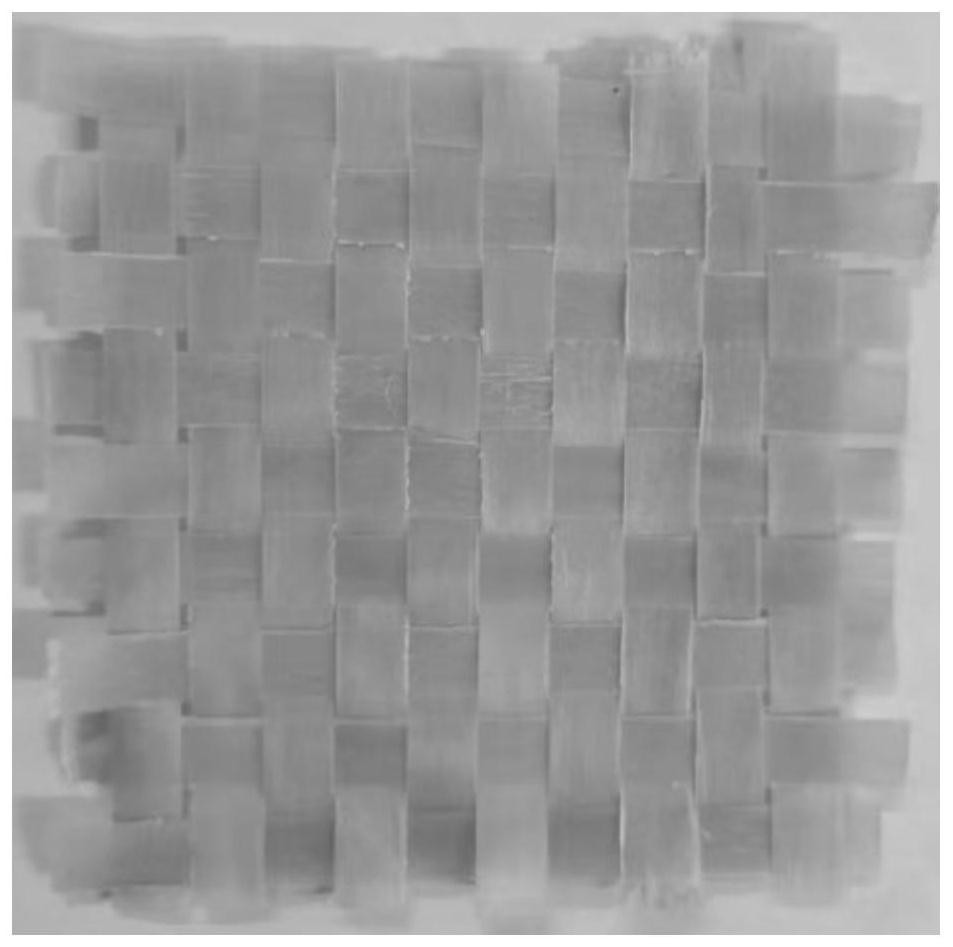

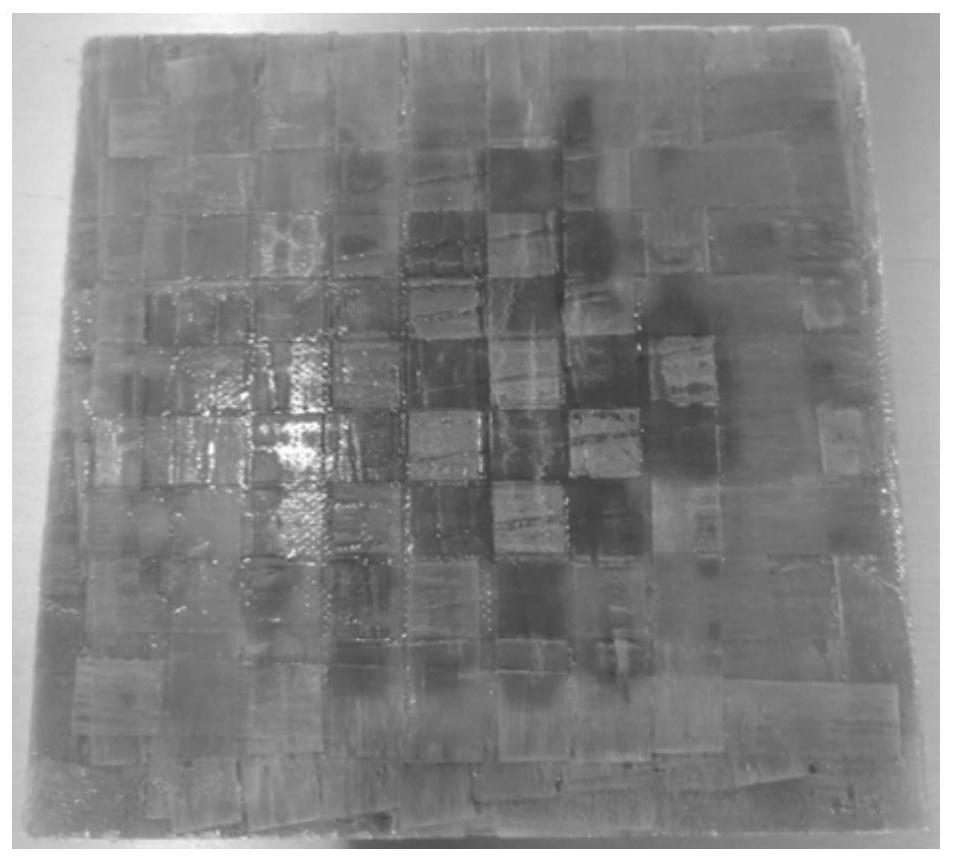

[0051] Poplar was selected as raw material, and the poplar veneer with a thickness of 200 μm was prepared by rotary cutting, as shown in figure 1 As shown, 50 veneers are immersed in a container containing a mixed solution of sodium hydroxide and sodium sulfite (wherein the concentration of sodium hydroxide is 0.1mol / L, and the concentration of sodium sulfite is 1mol / L), the volume of the solution is 500mL, water Cook for 30 minutes, then take out the wood veneer and wash it with distilled water for 3 times. Add 500 mL of water to the container again, add it to the aqueous solution of hydrogen peroxide (the mass fraction of hydrogen peroxide accounts for 10% of the total solution), boil in water for 1 hour, take it out, wash it with distilled water 3 times, and dry it. Align the wood veneers along the same direction, assemble the blanks, place them in the mold of the cold press, apply high pressure, raise the temperature to 120°C, cool to room temperature after 3 hours, remove...

Embodiment 2

[0053] Poplar was selected as a raw material, and poplar veneers with a thickness of 200 μm were prepared by rotary cutting, and 50 veneers were immersed in a container containing a mixed solution of sodium hydroxide and sodium sulfite (wherein the concentration of sodium hydroxide was 0.2 mol / L, the concentration of sodium sulfite is 0.8mol / L), the solution volume is 500mL, boiled in water for 30min, then the wood veneer is taken out, and washed with distilled water for 3 times. Add 500 mL of water to the container again, add it to the aqueous solution of hydrogen peroxide (the mass fraction of hydrogen peroxide accounts for 10% of the total solution), boil in water for 1 hour, take it out, wash it with distilled water 3 times, and dry it. Align the wood veneers along the same direction, assemble the blanks, place them in the mold of the cold press, apply high pressure, raise the temperature to 120°C, cool to room temperature after 3 hours, remove the mold, take out the slabs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com