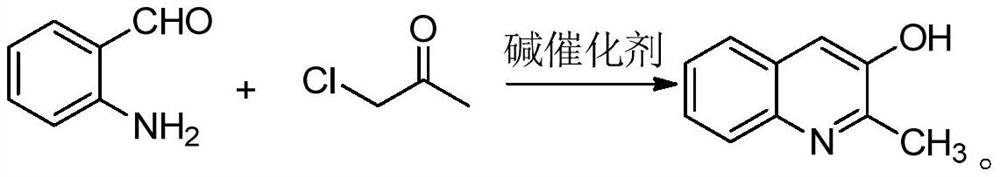

Synthesis method of 2-methyl-3-hydroxyquinoline and preparation method of quinotrione disperse dye

A synthesis method and technology of hydroxyquinoline, applied in the direction of azo dyes, organic dyes, chemical instruments and methods, etc., can solve the problem of increasing the preparation cost of quinone disperse dyes and reducing 2-methyl-3-hydroxyquinoline Yield, instability and other problems, to achieve the effect of improving reaction selectivity, increasing yield and increasing reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

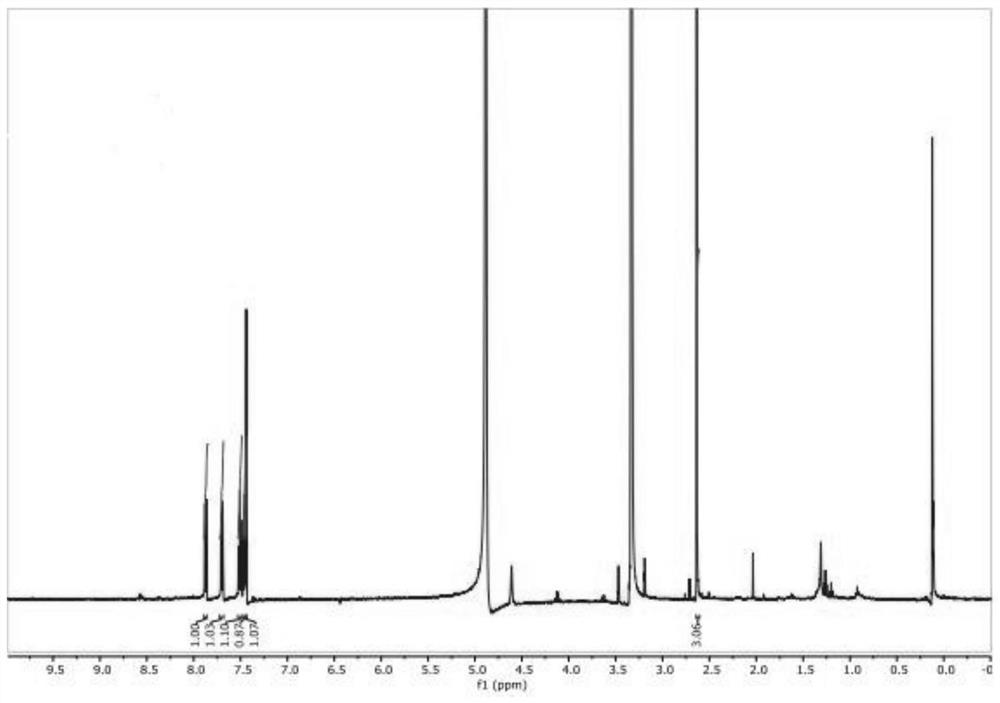

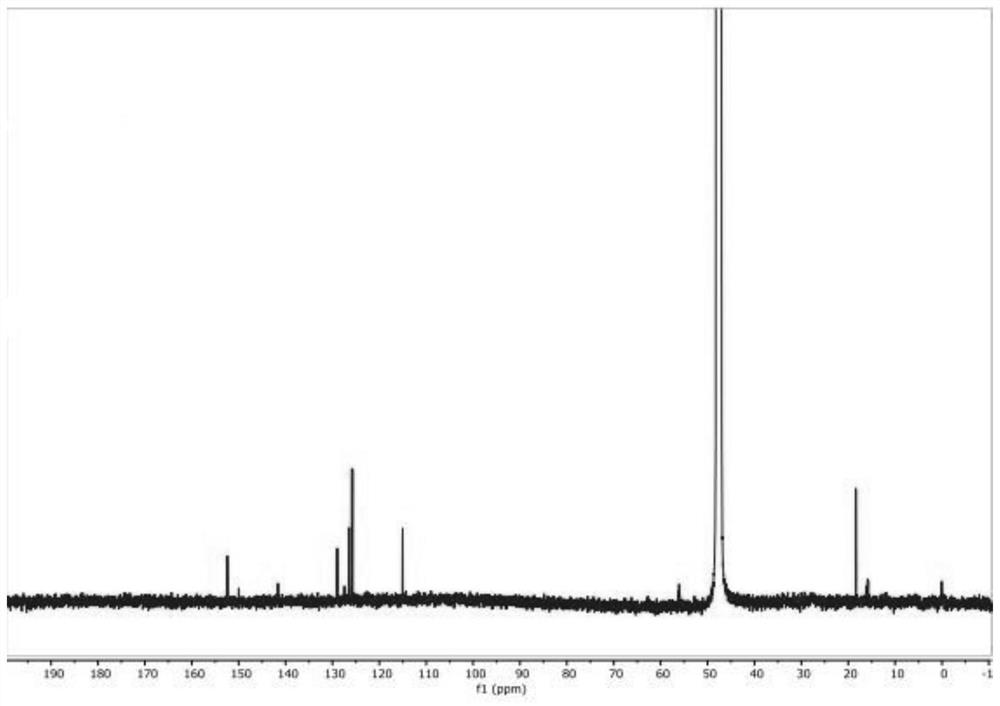

Examples

preparation example Construction

[0037] One embodiment of the present invention provides a synthesis method of 2-methyl-3-hydroxyquinoline, comprising the following steps S10-S20.

[0038] Step S10, mixing anthranilaldehyde, chloroacetone, base catalyst, phase transfer catalyst and solvent, and adjusting the pH value to 11-13 to obtain a mixed solution.

[0039] First, anthranilaldehyde, chloroacetone, alkali catalyst, phase transfer catalyst and solvent are mixed, and under the action of the phase transfer catalyst, all raw materials are fully contacted to obtain a homogeneously mixed solution, thereby improving the efficiency of subsequent reactions.

[0040] The technicians of the present invention have found through in-depth research: although o-aminobenzaldehyde and chloroacetone pass through the microchannel reaction under the effect of an alkali catalyst, the ring-forming reaction can occur rapidly to obtain 2-methyl-3-hydroxyquinoline; yet, During the microchannel reaction process, the reactivity of o...

Embodiment 1

[0090] 1) Anthranilaldehyde, chloroacetone and tetrabutylammonium bromide are dissolved in tetrahydrofuran to form a first solution; sodium hydroxide and zinc oxide are dissolved in water to form a second solution. The first solution and the second solution are then mixed to obtain a mixed solution. Wherein, the mass ratio of o-aminobenzaldehyde, chloroacetone, tetrabutylammonium bromide, sodium hydroxide and zinc oxide in the mixed solution is: 1:0.6:0.1:0.6:0.08. The pH value of the mixed solution = 12.1.

[0091] 2) Pump the mixed solution obtained in step 1) into a preheater to preheat to 30°C to obtain a preheated reaction solution; then pump the preheated reaction solution into a microchannel reactor, and keep warm at 30°C for reaction, wherein The flow rate of the mixed solution is 50mL / min; the product obtained by the reaction enters the separation tank for separation treatment to obtain 2-methyl-3-hydroxy-quinoline.

[0092] 3) Calculate the yield of 2-methyl-3-hydr...

Embodiment 2

[0096] 1) Anthranilaldehyde, chloroacetone and tetrabutylammonium bromide are dissolved in tetrahydrofuran to form a first solution; sodium hydroxide and zinc oxide are dissolved in water to form a second solution. The first solution and the second solution are then mixed to obtain a mixed solution. Wherein, the mass ratio of o-aminobenzaldehyde, chloroacetone, tetrabutylammonium bromide, sodium hydroxide and zinc oxide in the mixed solution is: 1:0.6:0.2:0.9:0.08. The pH value of the mixed solution = 12.8.

[0097] 2) Pump the mixed solution obtained in step 1) into a preheater to preheat to 30°C to obtain a preheated reaction solution; then pump the preheated reaction solution into a microchannel reactor, and keep warm at 30°C for reaction, wherein The flow rate of the mixed solution is 50mL / min; the product obtained by the reaction enters the separation tank for separation treatment to obtain 2-methyl-3-hydroxy-quinoline.

[0098] 3) The yield of 2-methyl-3-hydroxy-quinol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com