Process for extracting non-denatured II-type collagen from sturgeon cartilage

A collagen and non-denaturing technology, which is applied in the field of food processing, can solve the problems of low yield of active substances and waste of active ingredients, and achieve the effects of shortening the production cycle, high output, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

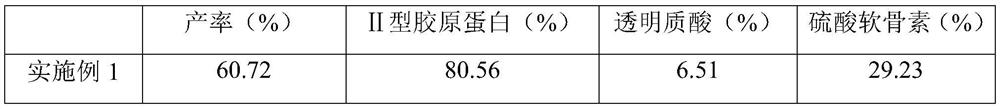

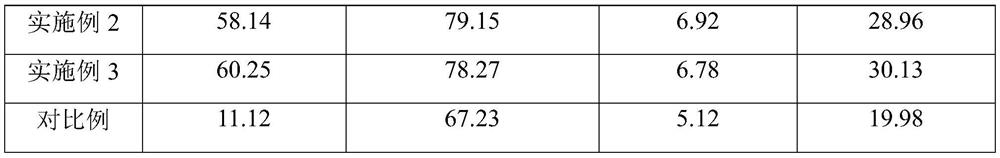

Examples

Embodiment 1

[0027] This example provides a process for extracting non-denatured type II collagen from sturgeon cartilage, which is prepared by degreasing, cooking, freezing, drying and grinding the cartilage in the head and / or bone of sturgeon .

[0028] Before degreasing, the head and / or bones of the sturgeon are sorted to remove the cartilage.

[0029] Among them, degreasing refers to putting the selected cartilage into a NaOH solution with a mass fraction of 4% and a temperature of 47°C for cleaning and degreasing, so as to remove adhesions on the surface of the cartilage such as fish meat, fish skin, blood vessels, mucous membranes, and nerves. Tissues and fish scales are then rinsed with solution pH to neutral on the cartilage surface. Specifically, the mass of NaOH solution is 5-10 times that of cartilage.

[0030] Among them, cooking refers to sending the cleaned cartilage into a continuous steam heating device, and the temperature of the heating zone rises from 80°C to 142°C. P...

Embodiment 2

[0035] This example provides a process for extracting non-denatured type II collagen from sturgeon cartilage, which is prepared by degreasing, cooking, freezing, drying and grinding the cartilage in the head and / or bone of sturgeon .

[0036] Before degreasing, the head and / or bones of the sturgeon are sorted to remove the cartilage.

[0037] Among them, degreasing refers to putting the selected cartilage into a NaOH solution with a mass fraction of 5% and a temperature of 50°C for cleaning and degreasing to remove adhesions on the surface of the cartilage such as fish meat, fish skin, blood vessels, mucous membranes, and nerves. Tissues and fish scales are then rinsed with solution pH to neutral on the cartilage surface.

[0038] Among them, cooking refers to sending the cleaned cartilage into a continuous steam heating device, and the temperature of the heating zone rises from 78°C to 140°C. Preferably, the cooking is carried out in a continuous steam heating tunnel, and t...

Embodiment 3

[0043] This example provides a process for extracting non-denatured type II collagen from sturgeon cartilage, which is prepared by degreasing, cooking, freezing, drying and grinding the cartilage in the head and / or bone of sturgeon .

[0044] Before degreasing, the head and / or bones of the sturgeon are sorted to remove the cartilage.

[0045] Among them, degreasing refers to putting the selected cartilage into a NaOH solution with a mass fraction of 3% and a temperature of 45°C for cleaning and degreasing, so as to remove adhesions on the surface of the cartilage such as fish meat, fish skin, blood vessels, and mucous membranes. , nerve tissue and fish scales, and then wash the cartilage surface to a neutral pH solution.

[0046] Among them, cooking refers to sending the cleaned cartilage into a continuous steam heating device, and the temperature of the heating zone rises from 82°C to 144°C. Preferably, cooking is carried out in a continuous steam heating tunnel, and the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com