3D printable and transparent conductive ion gel and its preparation and application

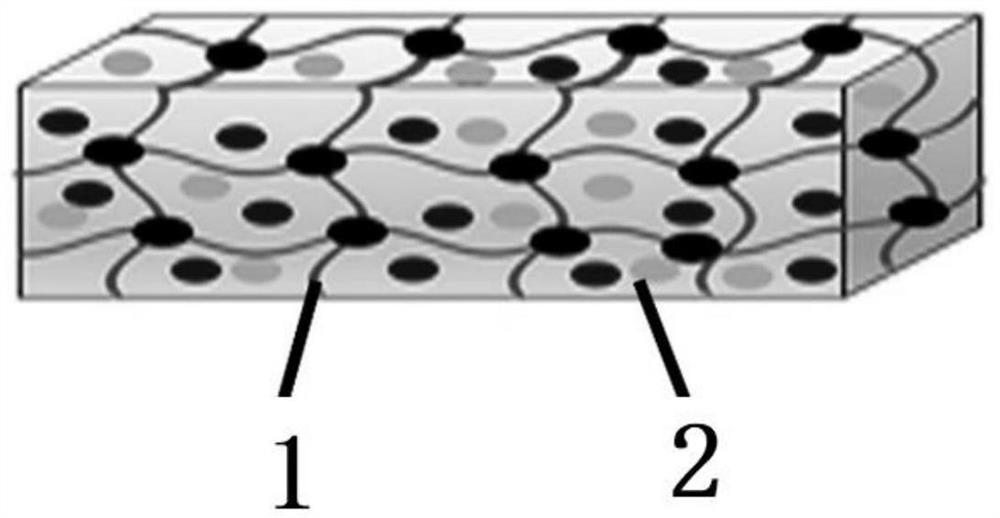

A conductive ion, 3D printing technology, applied in flexible conductive gel, transparent field, to achieve high conductivity, good electromechanical performance, wide working temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] This embodiment provides a preparation method of PUU polymer, the specific steps are as follows:

[0072] (1) Weigh 4.00g (2mmol) PEG (Mn=2000g / mol) in a 100mL three-neck flask, place it in a vacuum oven at 80°C to dry overnight, and place a small amount of phosphorus pentoxide in the vacuum oven at the same time to facilitate Remove all water. After drying, take out the three-necked flask, place it in an oil bath at normal temperature, add 10 mL of DMAC dried in advance with anhydrous sodium sulfate into the three-necked flask with a measuring cylinder, and add a magnet to stir. Then 0.1480 g (1 mmol) of dimethylolbutyric acid (DMBA), 4.00 g (18 mmol) of isophorone diisocyanate (IPDI) and 20 μL of dibutyltin dilaurate (catalyst) were added.

[0073] (2) The above mixture was heated to 70°C and then heated and stirred for 4 hours, then the reaction system was cooled to 50°C, and 18 mmol of H 2 O continued to stir the reaction. After adding water, as the reaction proc...

Embodiment 2

[0076] This embodiment provides a preparation method of conductive ion gel, the specific steps are as follows:

[0077] Take 1.0g of the PUU polymer prepared in Example 1 in a 10mL glass bottle, add 0.25g of 1-ethyl-3-methylimidazolium dicyandiamide salt, then add 4g of methanol, heat on a stirrer at 50°C to dissolve, and wait After the sample is dissolved, the solution is poured into a polytetrafluoroethylene mold of 5cm×5cm×1cm, and filter paper is placed on the mold to prevent bubbles from appearing when the methanol volatilizes too quickly. Dry naturally at room temperature for 1-2 days, and then place in a vacuum drying oven at 40° C. for further drying until constant weight to obtain a conductive ion gel with 20 wt % ionic liquid content.

Embodiment 3

[0079] This embodiment provides a preparation method of conductive ion gel, the specific steps are as follows:

[0080] Take 1.0g of the PUU polymer prepared in Example 1 in a 10mL glass bottle, add 0.43g of 1-ethyl-3-methylimidazolium dicyandiamide salt, then add 4g of methanol, heat on a stirrer at 50°C to dissolve, and wait After the sample is dissolved, the solution is poured into a polytetrafluoroethylene mold of 5cm×5cm×1cm, and filter paper is placed on the mold to prevent bubbles from appearing when the methanol volatilizes too quickly. Dry naturally at room temperature for 1-2 days, and then place in a vacuum drying oven at 40° C. for further drying until constant weight to obtain a conductive ion gel with 30 wt % ionic liquid content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

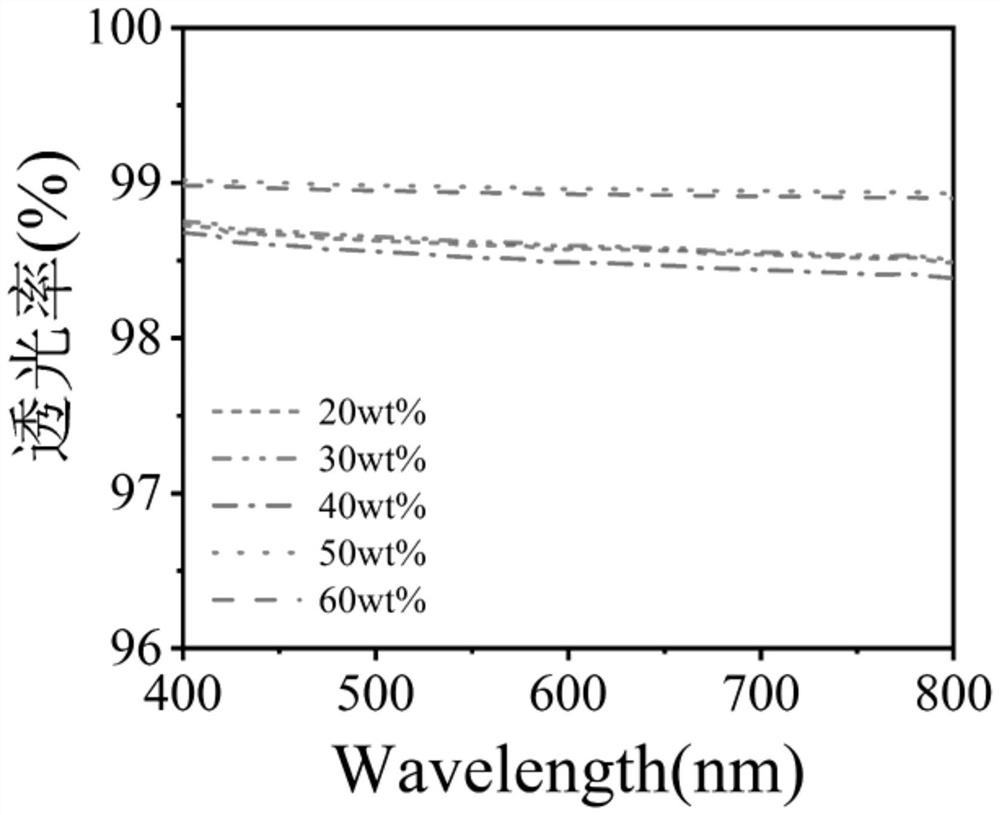

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com