Preparation method of cesium-lead halogen perovskite nanocrystalline film with high luminous efficiency

A high luminous efficiency, cesium lead halide technology, applied in nanotechnology, nanotechnology, nanooptics, etc. for materials and surface science, can solve problems such as difficult to popularize, high operation requirements, and fast film formation speed, and achieves a high level of improvement. Luminous Efficiency and Stability, Control of Quantum Dot Size, Effect of Improving Luminous Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A method for preparing a cesium lead halide perovskite nanocrystalline film with high luminous efficiency, specifically comprising the following steps:

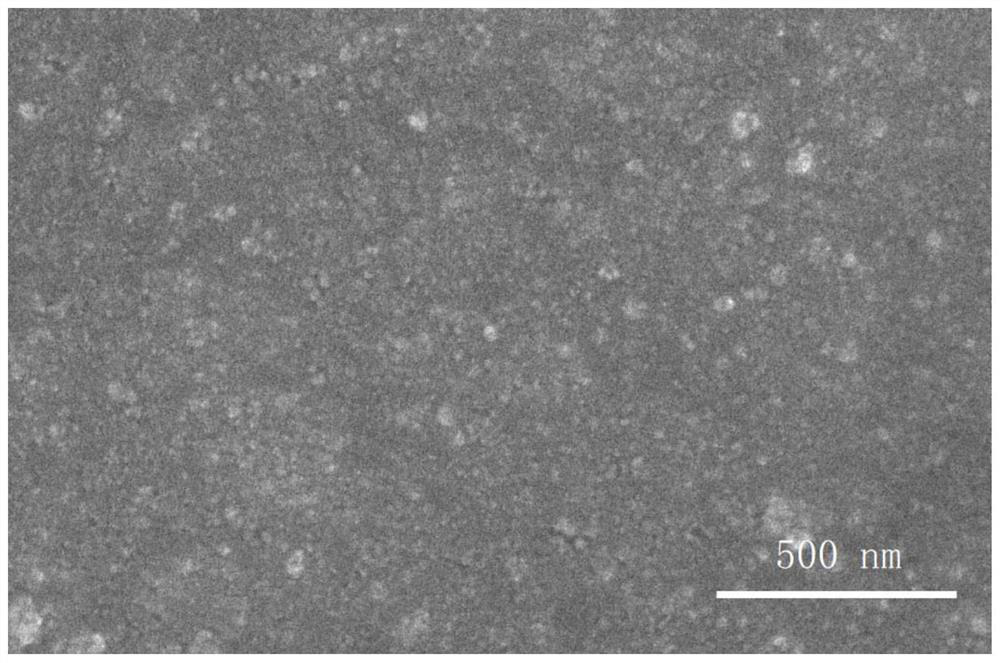

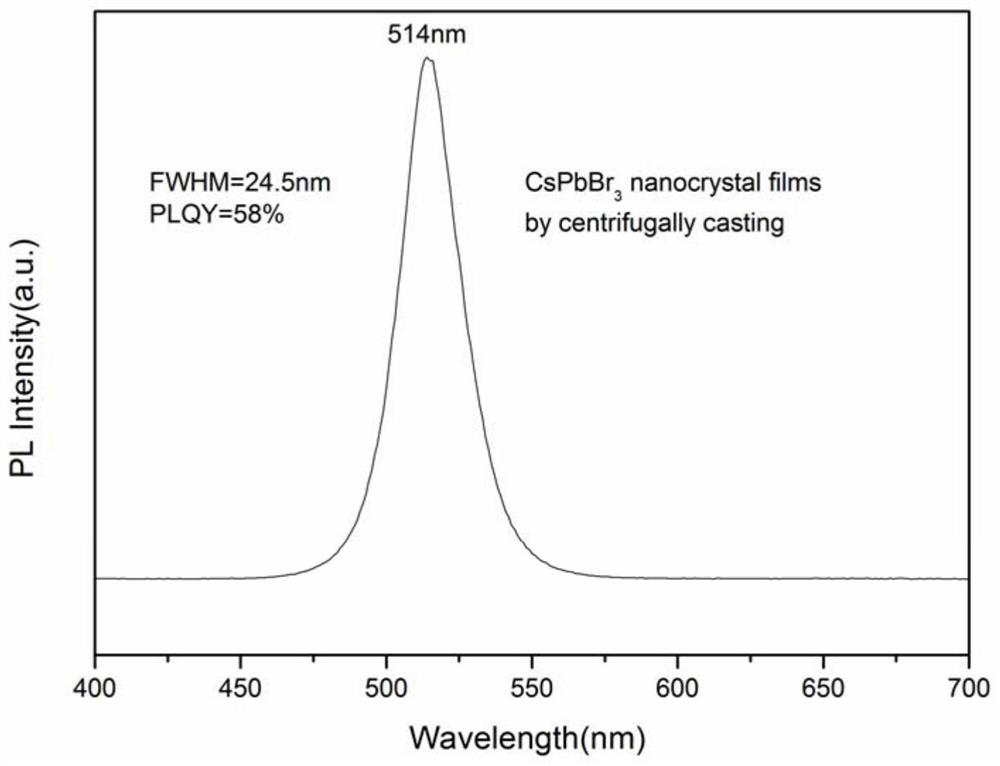

[0040](1) A quantum dot solution preparation step, take 20mL of N,N-dimethylformamide (DMF), 2mL of oleic acid and 0.4mL of oleylamine, the volume ratio of the three reagents is 10:1:0.2 , Stir and mix the above three reagents evenly before use; weigh 0.8 mmol of CsBr and PbBr with a purity of analytical grade according to the molar ratio of 1:1 2 Add to the mixed solution of DMF, oleic acid and oleylamine, each solute concentration is 0.04mol / L, stir on the mixer for 10min, after standing for 30min, take the supernatant to obtain the precursor solution; take 1mmol of 3-aminopropane Mix triethoxysilane (APTES) with 2mL of DMF evenly to obtain an APTES solution with a Si element concentration of 0.5mol / L; take 1mL of the precursor solution and 80μL of APTES solution and mix evenly, at this time the Pb:Si in the solution...

Embodiment 2

[0046] A method for preparing a cesium lead halide perovskite nanocrystalline film with high luminous efficiency, specifically comprising the following steps:

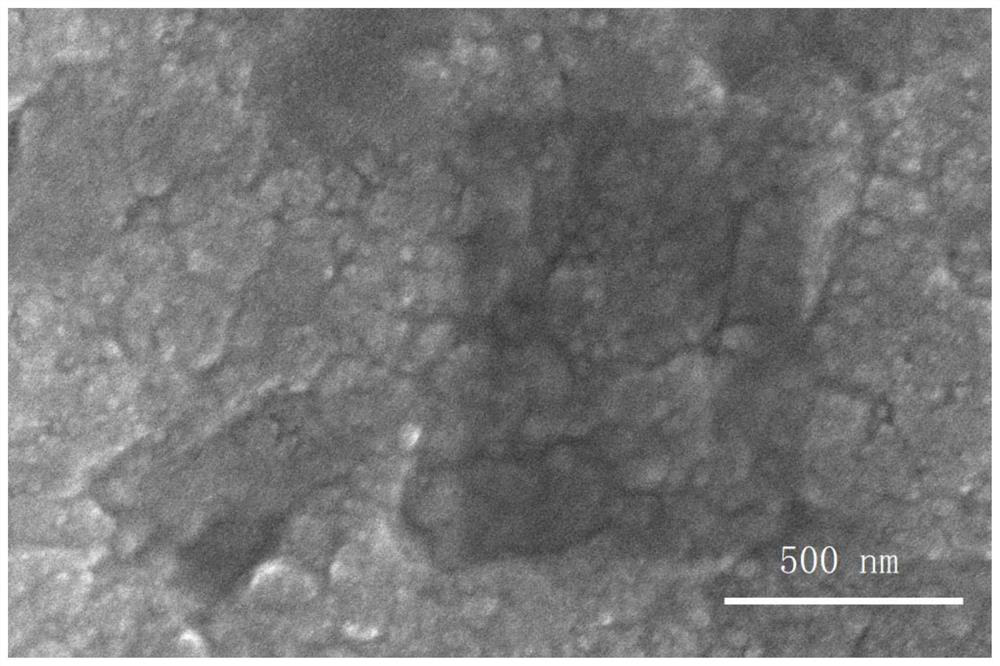

[0047] (1) A quantum dot solution preparation step, take 10mL of N,N-dimethylformamide (DMF), 1mL of oleic acid and 0.15mL of oleylamine, the volume ratio of the three reagents is 10:1:0.15 , Stir and mix the above reagents evenly before use; weigh 0.8 mmol of CsBr and PbBr with a purity of analytical grade according to the molar ratio of 1:1 2 Add to the mixed solution of DMF, oleic acid and oleylamine, each solute concentration is 0.08mol / L, stir on the mixer for 15min, after standing for 40min, take the supernatant to obtain the precursor solution; take 1mmol of 3-aminopropane APTES solution with Si element concentration of 0.5mol / L was obtained after mixing homogeneously with 2mL of DMF; 1mmol of NaBr was added to 10mL of DMF, and NaBr was completely dissolved in DMF by stirring. Obtain a NaBr solution with a conc...

Embodiment 3

[0053] A method for preparing a cesium lead halide perovskite nanocrystalline film with high luminous efficiency, specifically comprising the following steps:

[0054] (1) A quantum dot solution preparation step, take 10mL of N,N-dimethylformamide (DMF), 1.5mL of oleic acid and 0.1mL of oleylamine, the volume ratio of the three reagents is 10:1.5: 0.1, stir and mix the above reagents evenly before use; weigh 0.4mmol of CsBr of analytical grade and 0.2mmol of PbBr respectively 2 and 0.2mmol of PbCl 2 Added to the mixed solution of DMF, oleic acid and oleylamine, Cs + and Pb 2+ The concentration of ions is 0.04mol / L, stir on the mixer for 20min, and after standing for 45min, take the supernatant to obtain the precursor solution; take 1mmol of 3-aminopropyltriethoxysilane (APTES) and 2mL of DMF After mixing evenly, obtain an APTES solution with a Si element concentration of 0.5mol / L; take 1mL of the precursor solution and 70μL of APTES solution and mix evenly, at this time the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com