Hyaluronic acid artesunate, nano-micelle preparation of hyaluronic acid artesunate, and preparation method and use of nano-micelle preparation

A technology of artesunate and nano micelles, applied in nanotechnology, nanotechnology, nanomedicine, etc., to achieve the effects of good responsive release characteristics, strong tumor cytotoxicity, and strong targeting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

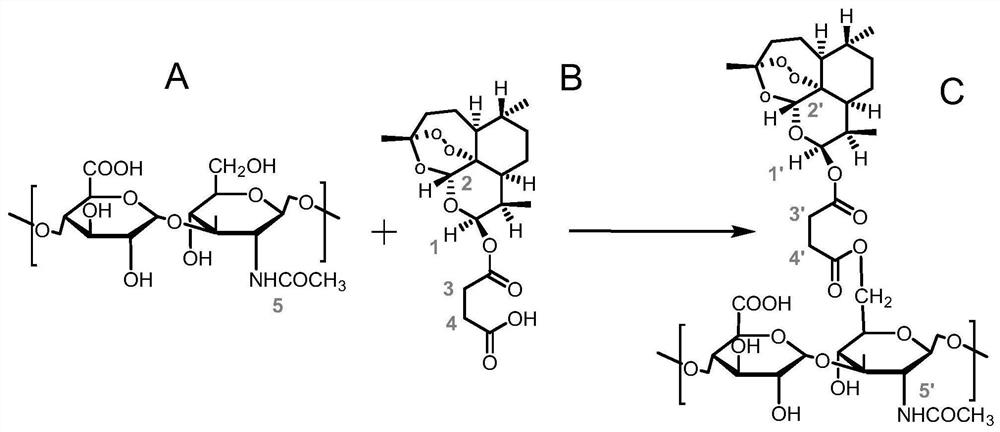

Method used

Image

Examples

Embodiment 1

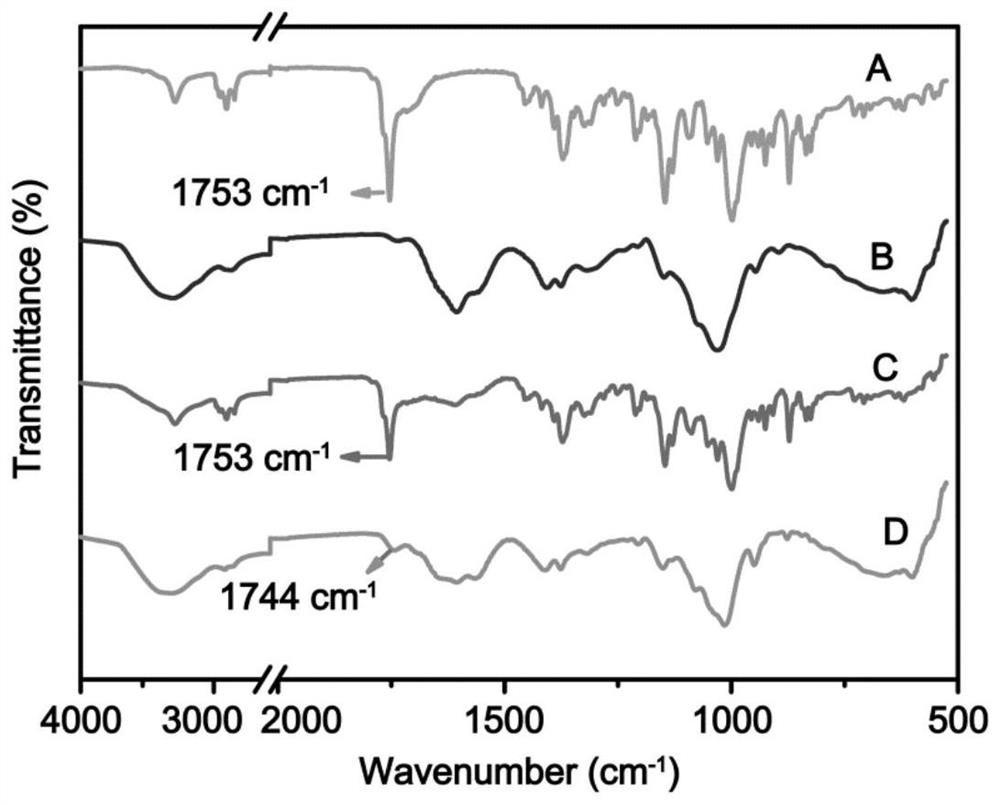

[0048] (1) Dissolve ASA in dimethyl sulfoxide, add the activator EDC·HCl according to the molar ratio of ASA and activator as 1:2, carry out carboxyl activation at 45°C for 0.5h under the protection of nitrogen, and then add The formamide solution of HA, the molar ratio of ASA to HA is 1:2, and the esterification reaction is carried out at 45°C for 48h under the protection of nitrogen;

[0049](2) Dialyzing the material obtained in step (1) to obtain HA-ASA dialyzate;

[0050] (3) After the HA-ASA dialysate obtained in step (2) is vacuum freeze-dried, the corresponding HA-ASA raw material is obtained;

[0051] (4) Dissolving the HA-ASA raw material obtained in step (3) in dimethyl sulfoxide to obtain an organic solution of HA-ASA, and ultrasonically dispersing at room temperature for 0.5 h;

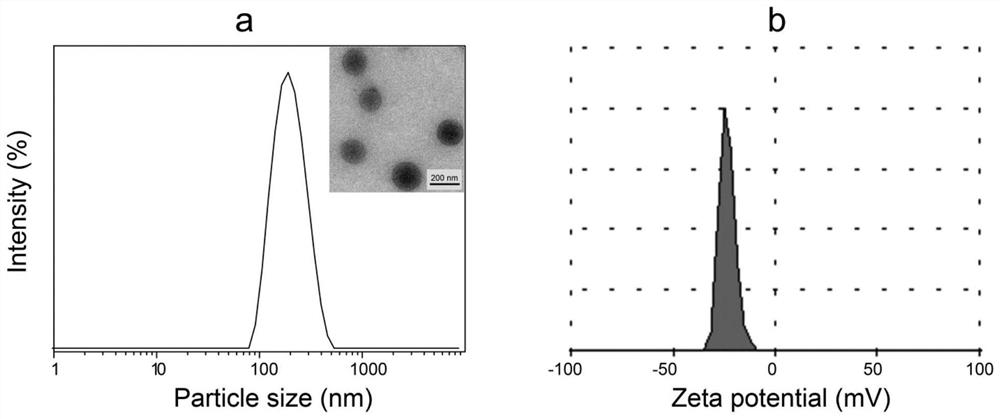

[0052] (5) The organic solution of HA-ASA obtained in step (4) was slowly added to 9 times the volume of deionized water, placed on a shaking table at room temperature for 3 hours, and t...

Embodiment 2

[0056] (1) Dissolve ASA in dimethyl sulfoxide, add the activator EDC·HCl according to the molar ratio of ASA and activator at a ratio of 1:2, carry out carboxyl activation at 50°C for 1 h under nitrogen protection, and then add HA formamide solution, the molar ratio of ASA to HA is 1:2, and the esterification reaction is carried out at 50°C for 36h under the protection of nitrogen;

[0057] (2) Dialyzing the material obtained in step (1) to obtain HA-ASA dialyzate;

[0058] (3) After the HA-ASA dialysate obtained in step (2) is vacuum freeze-dried, the corresponding HA-ASA raw material is obtained;

[0059] (4) dissolving the HA-ASA raw material obtained in step (3) in dimethyl sulfoxide to obtain an organic solution of HA-ASA; ultrasonically disperse at room temperature for 1 h;

[0060] (5) Slowly add the organic solution of HA-ASA obtained in step (4) to 9 times the volume of deionized water, place it on a shaker at room temperature for 1 hour, and then dissolve the HA-ASA...

Embodiment 3

[0064] (1) Dissolve ASA in dimethyl sulfoxide, add the activator EDC·HCI according to the molar ratio of ASA and activator as 1:2, carry out carboxyl activation at 45°C for 2 hours under the protection of nitrogen, and then add HA formamide solution, the molar ratio of ASA to HA is 1:2, and the esterification reaction is carried out at 45°C for 36h under the protection of nitrogen;

[0065] (2) dialyze the material obtained in step (1) to obtain HA-ASA dialysate;

[0066] (3) After the HA-ASA dialysate obtained in step (2) is vacuum freeze-dried, the corresponding HA-ASA raw material is obtained;

[0067] (4) Dissolving the HA-ASA raw material obtained in step (3) in N,N-dimethylformamide to obtain an organic solution of HA-ASA; ultrasonically disperse at room temperature for 0.5h;

[0068] (5) Slowly add the organic solution of HA-ASA obtained in step (4) to 9 times the volume of deionized water, place it on a shaker at room temperature for 3 hours, and then perform dialysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com