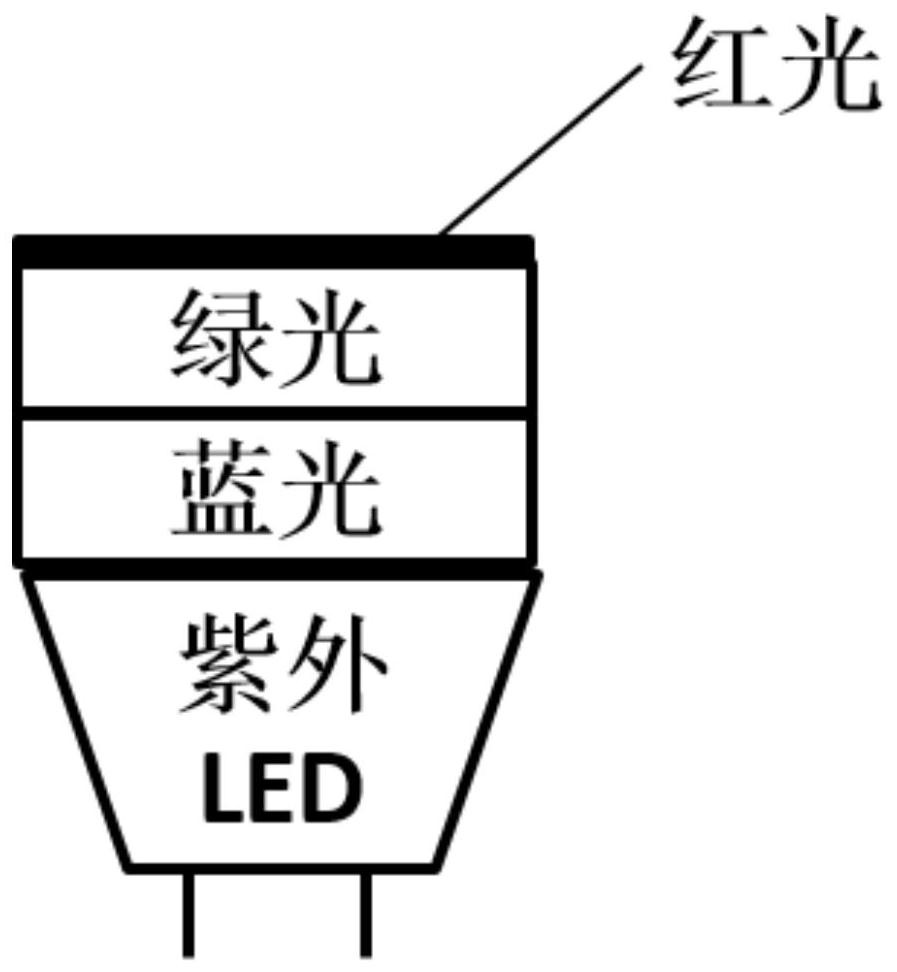

Preparation method and application of Zn < 2 + > doped CsPbBr3 nanocrystalline phosphosilicate glass

A technology of phosphosilicate glass and nanocrystals, which is applied in glass manufacturing equipment, glass molding, glass furnace equipment, etc., can solve the problems of different light attenuation of the three primary colors, unstable color temperature, etc., and achieve improved thermal stability and chemical stability. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

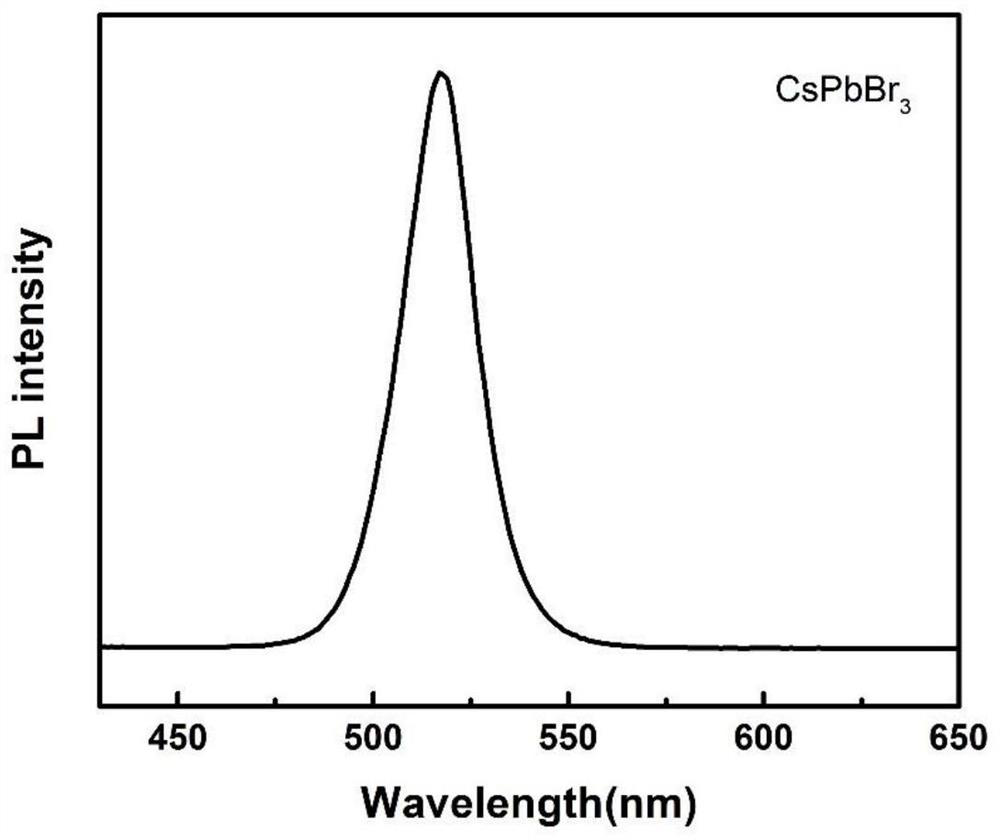

Embodiment 1

[0035] Weigh raw materials according to the following molar percentages:

[0036] P 2 o 5 : 56%, SiO 2 : 10%, Al 2 o 3 : 3%, SrCO 3 : 6%, Cs 2 CO 3 : 10%, PbBr 2 : 5%, NaBr: 10%;

[0037] Prepare the above CsPbBr as follows 3 Nanocrystalline phosphosilicate glass,

[0038] 1) Weigh the raw materials according to the molar percentage designed for the glass component, put them in a mixing bottle, add an appropriate amount of ethanol and zirconia mixing balls of appropriate size and proportion, and wet-mix ball milling for more than 12 hours to fully mix the raw materials evenly;

[0039] 2) After mixing evenly, transfer the raw materials from the mixing bottle to an evaporating dish, and place the evaporating dish in a blast drying oven for drying. After drying, transfer the raw materials from the evaporating dish to a corundum crucible, and put the Put the corundum crucible of the raw material into the electric melting furnace and melt it at 1200°C for 30 minutes;

...

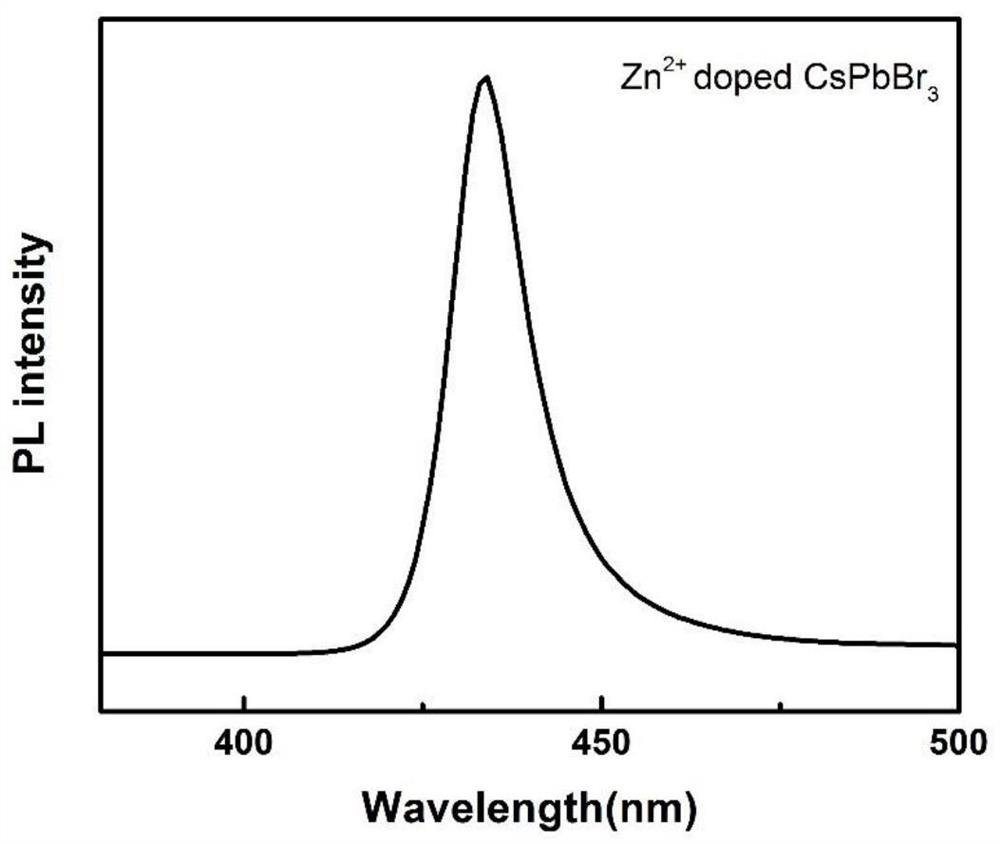

Embodiment 2

[0044] Weigh raw materials according to the following molar percentages:

[0045] P 2 o 5 : 56%, SiO 2 : 10%, Al 2 o 3 : 3%, SrCO 3 : 6%, Cs 2 CO 3 : 10%, PbBr 2 : 1%, NaBr: 10%; ZnBr 2 : 3%;

[0046] Prepare the above CsPbBr as follows 3 Nanocrystalline phosphosilicate glass,

[0047] 1) Weigh the raw materials according to the molar percentage designed for the glass component, put them in a mixing bottle, add an appropriate amount of ethanol and zirconia mixing balls of appropriate size and proportion, and wet-mix ball milling for more than 12 hours to fully mix the raw materials evenly;

[0048] 2) After mixing evenly, transfer the raw materials from the mixing bottle to an evaporating dish, and place the evaporating dish in a blast drying oven for drying. After drying, transfer the raw materials from the evaporating dish to a corundum crucible, and put the Put the corundum crucible of the raw material into the electric melting furnace, and melt it in the temper...

Embodiment 3

[0053] Weigh raw materials according to the following molar percentages:

[0054] P 2 o 5 : 56%, SiO 2 : 10%, Al 2 o 3 : 3%, SrCO 3 : 6%, Cs 2 CO 3 : 10%, PbBr 2 : 1%, NaBr: 10%; ZnBr 2 : 4%;

[0055] Prepare the above CsPbBr as follows 3 Nanocrystalline phosphosilicate glass,

[0056] 1) Weigh the raw materials according to the molar percentage designed for the glass component, put them in a mixing bottle, add an appropriate amount of ethanol and zirconia mixing balls of appropriate size and proportion, and wet-mix ball milling for more than 12 hours to fully mix the raw materials evenly;

[0057] 2) After mixing evenly, transfer the raw materials from the mixing bottle to an evaporating dish, and place the evaporating dish in a blast drying oven for drying. After drying, transfer the raw materials from the evaporating dish to a corundum crucible, and put the Put the corundum crucible of the raw material into the electric melting furnace, and melt it in the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com