Preparation method of marine environment-resistant magnetic wave-absorbing material

A magnetic and wave-absorbing coating technology, applied in the field of wave-absorbing materials, can solve the problems of long service life, complex process, inability to take into account stealth performance, and decline in stealth performance, and achieve low production costs, improve marine environment resistance, and simple methods Feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

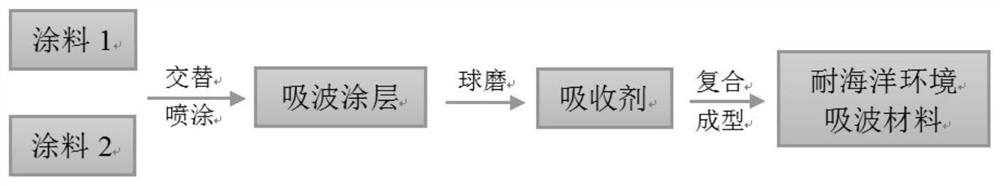

Method used

Image

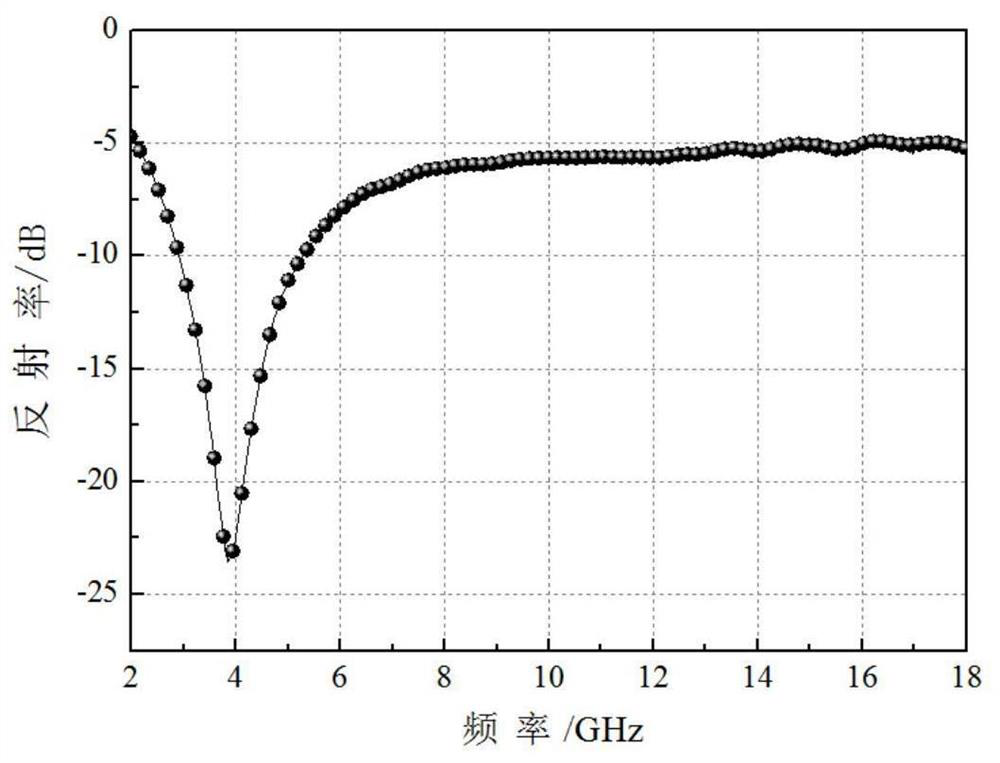

Examples

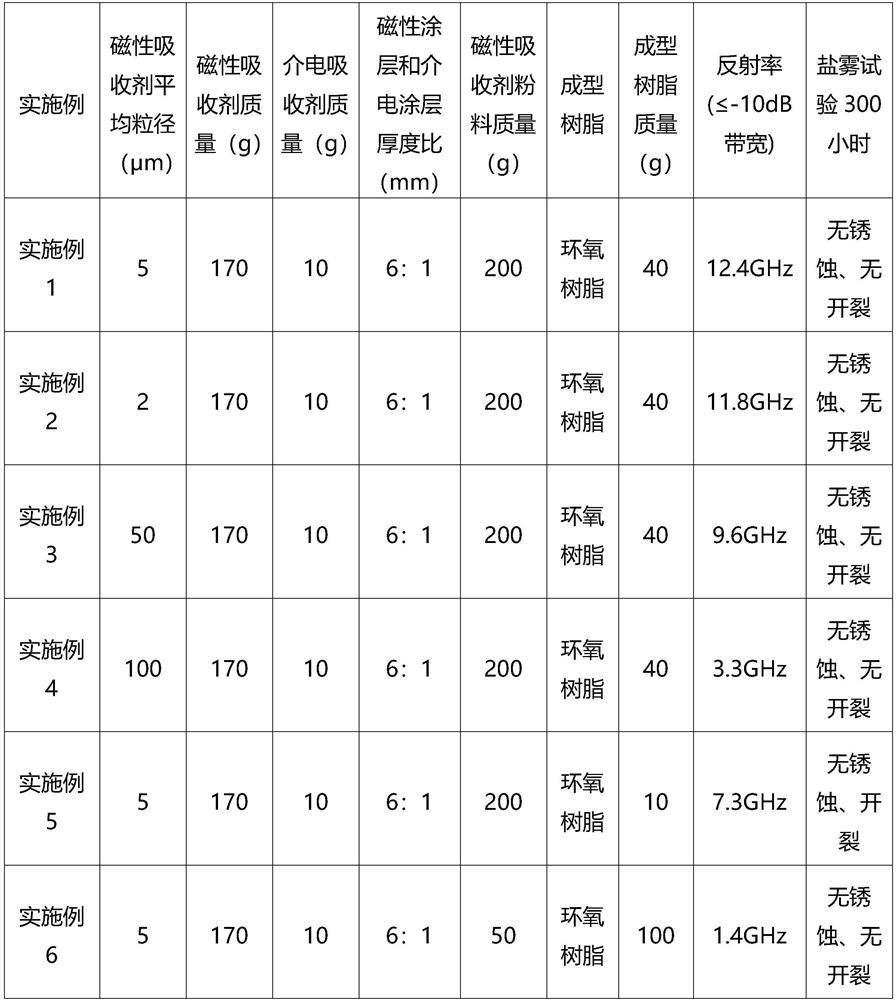

Embodiment 1

[0064] (1) Add 170g of carbonyl iron powder (as a magnetic absorbent) with an average particle size of 5 μm into 30g of epoxy resin, add 20g of xylene (as a diluent), and mechanically stir at a speed of 1500r / min for 1 hour to obtain Coating 1: Add 10 g of acetylene carbon black to 190 g of epoxy resin, add 20 g of xylene (as a diluent), and mechanically stir at a speed of 1500 r / min for 1 hour to prepare Coating 2. Pour the two kinds of coatings into the watering cans respectively, and spray them alternately according to the process of coating 2-surface dry-coating 1-surface dry-coating 2 to obtain a wave-absorbing coating with a thickness of 0.5mm, in which the magnetic coating and the dielectric coating The thickness ratio of the layers is 6:1, and the thickness of each dielectric layer is the same, and the thickness of each magnetic layer is the same, and put into a drying oven at 70° C. for 8 hours for curing.

[0065] (2) Mechanically crush the cured wave-absorbing coati...

Embodiment 2

[0069] Example 2 is basically the same as Example 1, except that the average particle size of the carbonyl iron powder in step (1) is 2 μm.

Embodiment 3

[0071] Example 3 is basically the same as Example 1, except that the average particle size of the carbonyl iron powder in step (1) is 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com