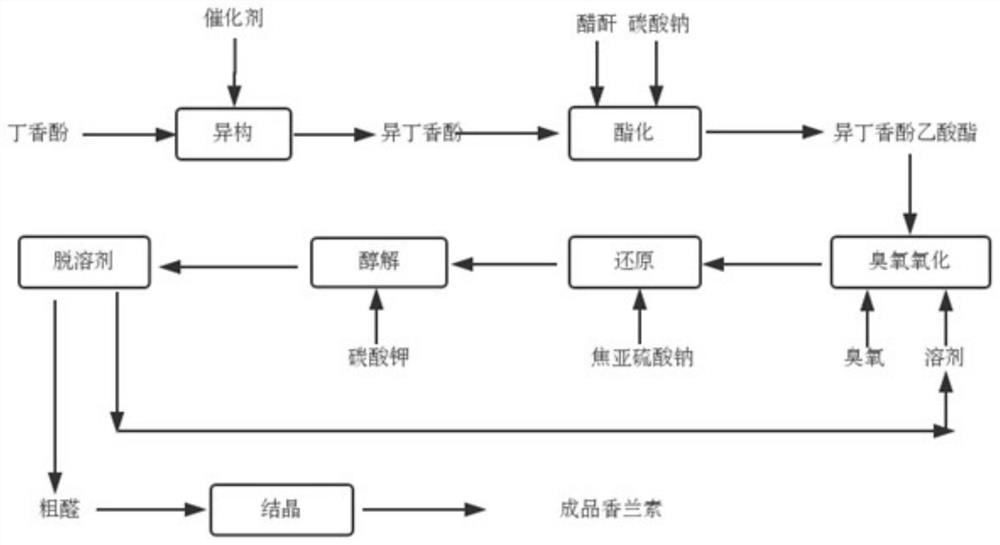

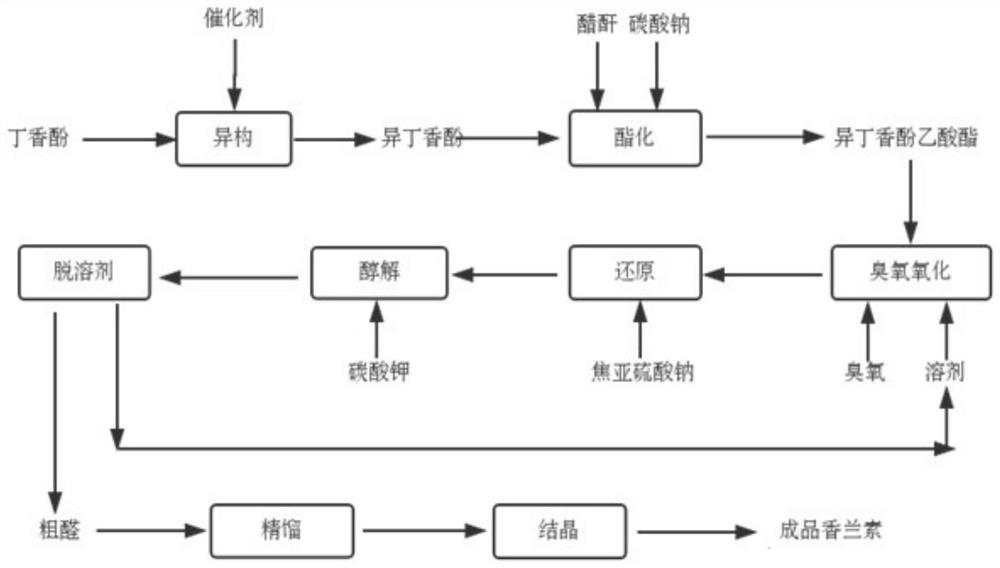

Method for synthesizing vanillin from eugenol through ozone oxidation

A technology of ozone oxidation and vanillin, applied in chemical instruments and methods, preparation of organic compounds, preparation of carbon-based compounds, etc., can solve problems such as low production yield and difficult wastewater treatment, and achieve fast reaction rate and less pollution , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The method that eugenol synthesizes vanillin through ozone oxidation, comprises the steps:

[0055] 1. Isomerization reaction:

[0056] Add 500 g of eugenol and 4.0 g of catalyst triphenylphosphine ruthenium chloride into the reactor and mix evenly, heat to 50-60° C. and keep the temperature for reaction for 4 hours until the content of eugenol is lower than 1%. Then directly carry out vacuum distillation to obtain 495 g of isoeugenol with a content of 98.5%, and the mass yield is 99%.

[0057] Add 500g of eugenol and 1g of new catalyst to the catalyst and part of the organic matter in the remaining kettle in the above example, and heat to 50-60°C to keep the temperature for 4-5 hours. When the eugenol content was lower than 1%, vacuum distillation was directly carried out to obtain 496 g of isoeugenol with a content of 98.4%, and the mass yield was 99%.

[0058] 2. Esterification reaction:

[0059] Add 10g of anhydrous sodium carbonate and 390g of acetic anhydride i...

Embodiment 2

[0067] The method that eugenol synthesizes vanillin through ozone oxidation, comprises the steps:

[0068] 1. Isomerization reaction:

[0069] Add 500 g of eugenol and 3.0 g of catalyst triphenylphosphine ruthenium chloride into the reactor and mix evenly, heat to 60-80° C. and keep the temperature for reaction for 4 hours until the content of eugenol is lower than 1%. Then directly carry out vacuum distillation to obtain 495 g of isoeugenol with a content of 98.5%, and the mass yield is 99%.

[0070] Add 500g of eugenol and 2g of new catalyst to the catalyst and part of the organic matter in the remaining kettle in the above example, and still heat to 60-80°C and keep the temperature for 5.0h. When the eugenol content was lower than 1%, vacuum distillation was directly carried out to obtain 495 g of isoeugenol with a content of 98.6%, and the mass yield was 99%.

[0071] 2. Esterification reaction:

[0072] Add 20g of anhydrous sodium acetate and 360g of acetic anhydride i...

Embodiment 3

[0079] The method that eugenol synthesizes vanillin through ozone oxidation, comprises the steps:

[0080] 1. Isomerization reaction:

[0081] Add 500 g of eugenol and 0.1 g of catalyst triphenylphosphine ruthenium chloride into the reactor and mix evenly, heat to 120-150°C and keep the temperature for reaction for 6 hours until the content of eugenol is lower than 1%. Then directly carry out vacuum distillation to obtain 491 g of isoeugenol with a content of 98.8%, and the mass yield is 98%.

[0082] Add 500g of eugenol and 0.03g of new catalyst to the catalyst and part of the organic matter in the remaining kettle in the above example, and heat to 120-150°C to keep the temperature for 4-5 hours. When the eugenol content was lower than 1%, vacuum distillation was directly carried out to obtain 495 g of isoeugenol with a content of 98.4%, and the mass yield was 99%.

[0083] 2. Esterification reaction:

[0084] Add 25g of anhydrous sodium carbonate and 400g of acetic anhydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com