Preparation method of poly(butylene adipate-co-terephthalate)/polylactic acid/starch ternary blended film blowing resin

A polybutylene terephthalate and adipate technology, which is applied in the field of materials, can solve the problems of poor water resistance of films, reduced material costs, and no resistance to humid environments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

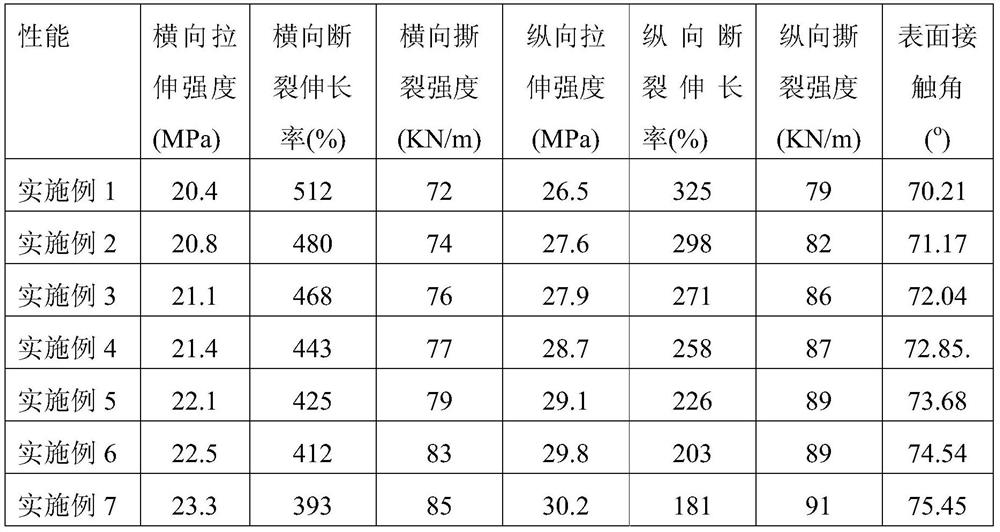

Examples

Embodiment 1

[0023] (1) Weigh 98.1 parts of starch, 1.5 parts of maleic anhydride, and 0.4 parts of titanate coupling agent; the order of addition is starch, maleic anhydride, and titanate coupling agent; turn the mixing speed to high speed and stir at high speed to 90°C, continue to stir for about 3 minutes to discharge, and obtain modified starch;

[0024] (2) Weigh 57 parts of PBAT, 24 parts of modified starch, 5 parts of polylactic acid, 9 parts of sorbitol liquid, 3 parts of talcum powder, 0.4 parts of erucamide, 0.5 parts of calcium stearate, ADR-4370F0.1 Part, 1 part of ethylene bis stearic acid amide;

[0025] (3) Add the raw materials into the high-speed mixer in a certain order, and the order of addition is PBAT, modified starch, polylactic acid, talcum powder, erucamide, calcium stearate, ethylene bisstearamide, ADR-4370F , Sorbitol liquid; the mixing speed is turned to high speed, and the material can be discharged after stirring at high speed for about 10 minutes;

[0026] (...

Embodiment 2

[0029] (1) Weigh 98.1 parts of starch, 1.5 parts of maleic anhydride, and 0.4 parts of aluminate coupling agent; the order of addition is starch, maleic anhydride, and aluminate coupling agent; turn the mixing speed to high speed and stir at high speed to 90°C, continue to stir for about 3 minutes to discharge, and obtain modified starch;

[0030] (2) Weigh 58 parts of PBAT, 20 parts of modified starch, 10 parts of polylactic acid, 8 parts of sorbitol liquid, 2.5 parts of talcum powder, 0.3 parts of erucamide, 0.5 parts of calcium stearate, ADR-4370F0.2 Part, 0.5 part of ethylene bis stearic acid amide;

[0031] (3) Add the raw materials into the high-speed mixer in a certain order, and the order of addition is PBAT, modified starch, polylactic acid, talcum powder, erucamide, calcium stearate, ethylene bisstearamide, ADR-4370F , Sorbitol liquid; the mixing speed is turned to high speed, and the material can be discharged after stirring at high speed for about 10 minutes;

[...

Embodiment 3

[0035] (1) Weigh 98.1 parts of starch, 1.5 parts of maleic anhydride, and 0.4 parts of silane coupling agent (KH550); the order of addition is starch, maleic anhydride, and silane coupling agent; 90°C, continue to stir for about 3 minutes to discharge, and obtain modified starch;

[0036] (2) Weigh 55 parts of PBAT, 18 parts of modified starch, 15 parts of polylactic acid, 8 parts of sorbitol liquid, 2.5 parts of talcum powder, 0.3 parts of erucamide, 0.5 parts of calcium stearate, ADR-4370F0.2 Part, 0.5 part of ethylene bis stearic acid amide;

[0037] (3) Add each raw material into the high-speed mixer in a certain order, and the order of addition is PBAT, modified starch, polylactic acid, talcum powder, erucamide, calcium stearate, ADR-4370F, ethylene bisstearamide , Sorbitol liquid; the mixing speed is turned to high speed, and the material can be discharged after stirring at high speed for about 10 minutes;

[0038] (4) Add the mixed raw materials into the hopper of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com