Rigid polyurethane foam plastic and preparation method thereof

A technology of rigid polyurethane and foam plastics, applied in the field of polyurethane materials, can solve the problems of reduced mechanical strength, poor miscibility, uneven cell density, etc., and achieve the effect of improving mechanical properties, improving compression performance, and obvious strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

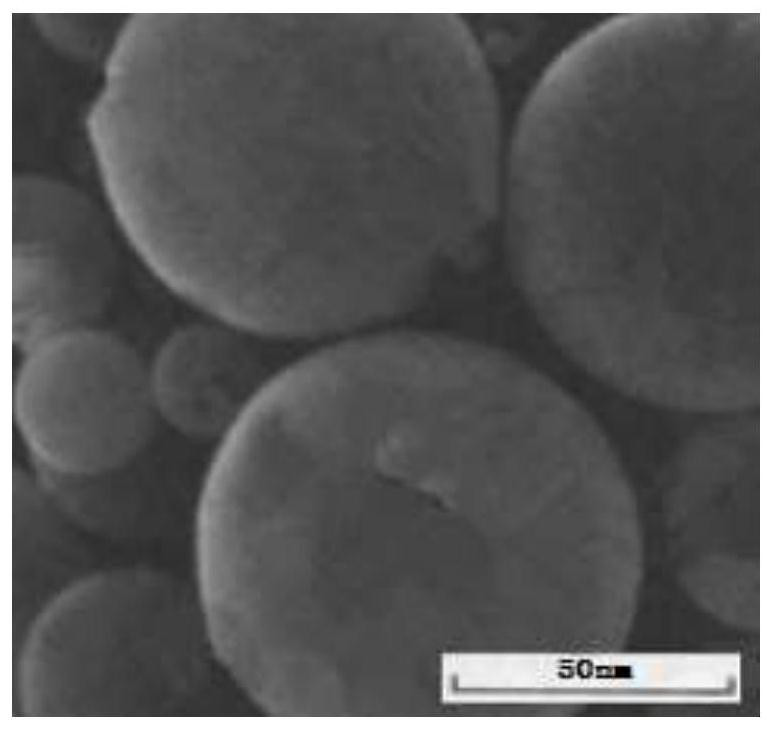

[0033] Preparation example 1 Nano microsphere reinforcing agent

[0034] Composition of raw materials (parts by weight): 5 parts of polyvinyl alcohol, 75 parts of styrene, 25 parts of N-isopropylacrylamide, 1 part of ammonium persulfate, 5 parts of polyethylene glycol 200, 200 parts of water and 30 parts of methanol.

[0035] It is prepared by the following method: after mixing polyvinyl alcohol, water and methanol and ultrasonically dispersing them uniformly, nitrogen gas is introduced, heated to 50°C, and 10wt% of the total amount of styrene and N-isopropyl are added for the first time Acrylamide, stirred and reacted for 1 hour, heated to 75°C, reacted for 5 hours, filtered, separated the beads, washed with water, added the beads to the aqueous solution containing ammonium persulfate and polyethylene glycol 200, and added the ammonium persulfate and polyethylene glycol 200 for the second time The total amount of 5wt% styrene and N-isopropylacrylamide was reacted at 75°C for ...

preparation example 2

[0036] Preparation Example 2 Nano-microsphere Reinforcing Agent

[0037] Raw material composition (parts by weight): 10 parts of polyvinyl alcohol, 100 parts of styrene, 50 parts of N-isopropylacrylamide, 2 parts of ammonium persulfate, 10 parts of polyethylene glycol 200, 350 parts of water and 70 parts of methanol.

[0038] It is prepared by the following method: after mixing polyvinyl alcohol, water and methanol and ultrasonically dispersing them uniformly, nitrogen gas is introduced, heated to 70°C, and 20wt% of the total amount of styrene and N-isopropyl are added for the first time Acrylamide, stirred and reacted for 3 hours, heated to 85°C, reacted for 10 hours, filtered, separated the beads, washed with water, added the beads to the aqueous solution containing ammonium persulfate and polyethylene glycol 200, and added the ammonium persulfate for the second time The total amount of 10wt% styrene and N-isopropylacrylamide was reacted at 85°C for 40 minutes, the remaining...

preparation example 3

[0039] Preparation Example 3 High-functionality polyester polyol

[0040] With 5 parts by weight of adipic acid, 5 parts by weight of ethylene glycol, 7 parts by weight of diethylene glycol, 2 parts by weight of butanediol, 0.5 parts by weight of dispersant polyethylene glycol 400, 50 parts by weight of toluene, 5 parts by weight of diethylene glycol Ethylene glycol and 0.1 parts by weight of azobis(2-methylbutyronitrile) were stirred and dissolved under nitrogen, and 10 parts by weight of styrene were added, and the temperature was raised to 60°C with stirring, and then stirred for 10 minutes, and the temperature was raised to 110°C to obtain Reaction solution; 2 parts by weight of adipic acid, 1 part by weight of ethylene glycol, 2 parts by weight of diethylene glycol, 1 part by weight of butanediol, 0.1 parts by weight of dispersant polyethylene glycol 400, 20 parts by weight of toluene , 0.01 parts by weight of azobis (2-methylbutyronitrile), 5 parts by weight of styrene t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com