Method for efficiently recycling and regenerating positive electrode material of waste lithium ion battery

A technology for lithium ion batteries and cathode materials, which is applied in the field of efficient recovery and regeneration of cathode materials of waste lithium ion batteries, can solve the problems of refractory waste acid treatment, equipment corrosion, human and environmental hazards, etc., and achieves saving steps, reducing process operations, Reduced effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

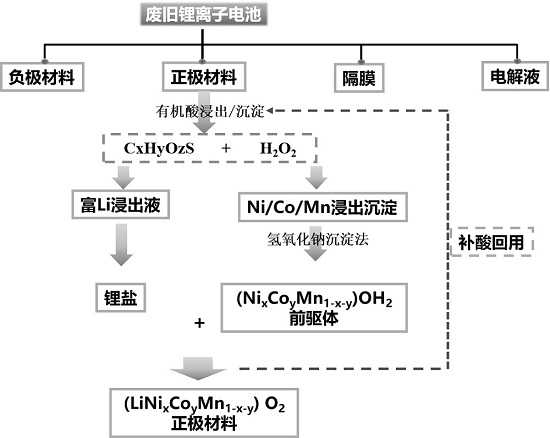

[0040] Such as figure 1 As shown, the method for high-priced recovery and regeneration of spent lithium-ion battery cathode materials comprises the following steps:

[0041] S1. First discharge the waste lithium-ion battery thoroughly, disassemble and peel off, and soak the obtained positive pole piece in N-methylpyrrolidone solution for ultrasonication to accelerate the separation of the positive active material from the aluminum foil of the current collector. After separation, dry the solid powder Calcination to obtain the positive electrode LiNi of waste batteries 0.5 co 0.2 mn 0.3 o 2 The active material is ground for later use.

[0042] S2. Weigh an appropriate amount of benzenesulfonic acid and place it in a 250mL three-neck flask, add deionized water, the concentration of benzenesulfonic acid is 0.1mol / L, and after the organic acid is completely dissolved, add a certain amount of hydrogen peroxide into the flask to configure the leaching agent, hydrogen peroxide is...

Embodiment 2

[0048] Such as figure 1 As shown, the method for high-priced recovery and regeneration of spent lithium-ion battery cathode materials comprises the following steps:

[0049] S1. First discharge the waste lithium-ion battery thoroughly, disassemble and peel off, and soak the obtained positive pole piece in N-methylpyrrolidone solution for ultrasonication to accelerate the separation of the positive active material from the aluminum foil of the current collector. After separation, dry the solid powder Calcination to obtain the positive electrode LiNi of waste batteries 0.5 co 0.2 mn 0.3 o 2 Active materials are ground for use;

[0050] S2. Weigh an appropriate amount of ethanesulfonic acid and place it in a 250mL three-neck flask, add deionized water, the concentration of benzenesulfonic acid is 0.5mol / L, and after the organic acid is completely dissolved, add a certain amount of hydrogen peroxide into the flask to configure Leaching agent, hydrogen peroxide is 5% of the to...

Embodiment 3

[0056] Such as figure 1 As shown, the method for high-priced recovery and regeneration of spent lithium-ion battery cathode materials comprises the following steps:

[0057] S1. First discharge the waste lithium-ion battery thoroughly, disassemble and peel off, and soak the obtained positive pole piece in N-methylpyrrolidone solution for ultrasonication to accelerate the separation of the positive active material from the aluminum foil of the current collector. After separation, dry the solid powder Calcination to obtain the positive electrode LiNi of waste batteries 0.5 co 0.2 mn 0.3 o 2 Active material, ground for use;

[0058] S2. Weigh an appropriate amount of vinylsulfonic acid and place it in a 250mL three-neck flask, add deionized water, the concentration of benzenesulfonic acid is 0.4mol / L, and after the organic acid is completely dissolved, add a certain amount of hydrogen peroxide into the flask to configure Leaching agent, hydrogen peroxide is 3% of the total v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com