Mesoporous hollow silicon dioxide nanospheres loaded with prolinol catalyst as well as preparation method and application of mesoporous hollow silicon dioxide nanospheres

A technology of mesoporous silica and silica, applied in the field of polymer materials and heterogeneous catalysis, can solve the problems of green chemistry obstacles, collapse, environmental pollution, etc., and achieve the effect of overcoming difficult activation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

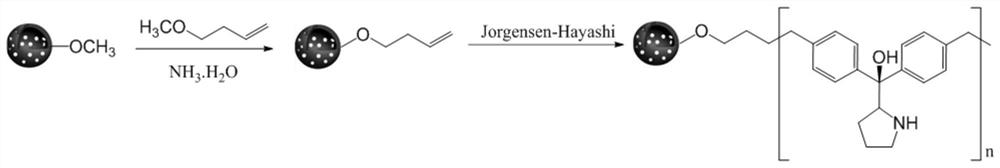

Method used

Image

Examples

Embodiment 1

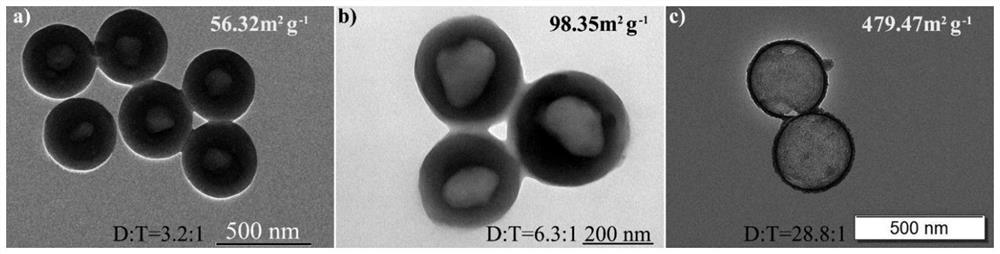

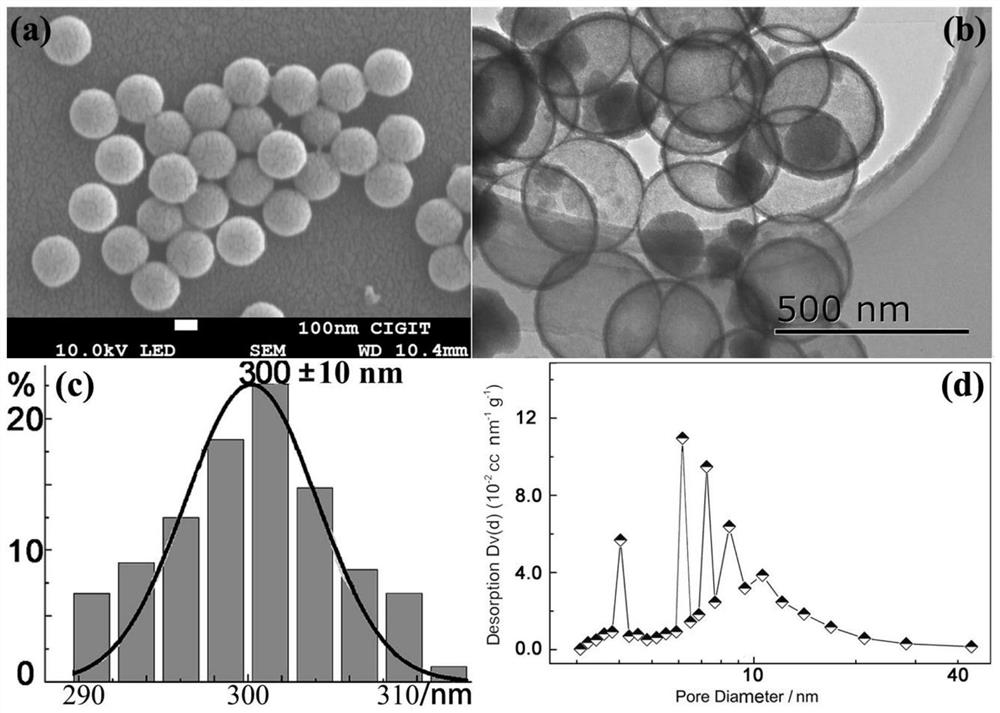

[0031] Weigh 0.35g of cetyltrimethylammonium bromide and 0.15g of 1,3,5-triisopropylbenzene, dissolve in a mixed solution of 16mL of ethanol, 64mL of deionized water and 1mL of ammonia water, add the dispersed PS / AA 20mL (200mg), kept heated in a water bath at 60°C, and stirred by magnetic force at 400r / min for 30min. Add 8 mL of tetraethyl orthosilicate dropwise within 15 minutes, keep the rotation speed and continue the reaction for 2 hours, then centrifuge the milky white solution to obtain solid particles. After washing with distilled water 2×8mL times and absolute ethanol 2×8mL times, put them into an oven at 80°C to dry for 24h. The dried product was then placed in a muffle furnace and calcined at 600 °C for 15 h (heating rate 2 °C min -1 ), cooled to room temperature to obtain hollow mesoporous silica nanospheres.

Embodiment 2

[0033]Weigh 0.35g of cetyltrimethylammonium bromide (CTAB) and 0.10g of 1,3,5-triisopropylbenzene, dissolve in a mixed solution of 16mL of ethanol, 64mL of deionized water and 1mL of ammonia water, add The dispersed PS / AA (400mg) was kept heated in a water bath at 60°C, and stirred by magnetic force at 400r / min for 30min. 8 mL of tetraethyl orthosilicate (TEOS) was added dropwise within 15 min, and the reaction was continued for 2 h while maintaining the rotational speed, and then the milky white solution was centrifuged to obtain solid particles. After washing with distilled water 2×8mL times and absolute ethanol 2×8mL times, put them into an oven at 80°C to dry for 24h. The dried product was then placed in a muffle furnace and calcined at 350 °C for 15 h (heating rate 3 °C min -1 ), cooled to room temperature to obtain hollow mesoporous silica nanospheres.

Embodiment 3

[0035] Weigh 0.35g of cetyltrimethylammonium bromide and 0.20g of 1,3,5-triisopropylbenzene, dissolve in a mixed solution of 16mL of ethanol, 64mL of deionized water and 1mL of ammonia water, add the dispersed PS / AA (1000mg), kept heated in a water bath at 60°C, and stirred by magnetic force at 400r / min for 30min. Add 8 mL of tetraethyl orthosilicate dropwise within 15 minutes, keep the rotation speed and continue the reaction for 2 hours, then centrifuge the milky white solution to obtain solid particles. After washing with distilled water 2×8mL times and absolute ethanol 2×8mL times, put them into an oven at 80°C to dry for 24h. The dried product was then placed in a muffle furnace and calcined at 800 °C for 15 h (heating rate 3 °C min -1 ), cooled to room temperature to obtain hollow mesoporous silica nanospheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com