Hydrothermal synthesis method of lithium iron manganese phosphate

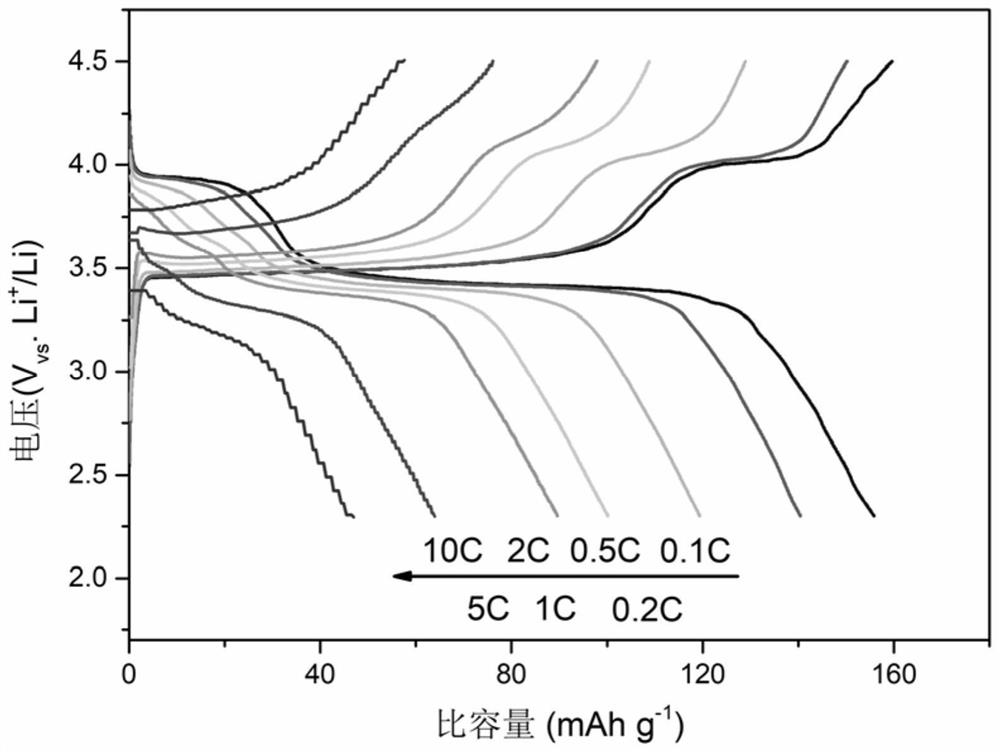

A technology of lithium manganese iron phosphate and hydrothermal synthesis, which is applied to the preparation/purification of phosphorus compounds, chemical instruments and methods, and carbon. It can solve the problems of large sample particle size and poor electrochemical performance, and achieve the specific capacity of charge and discharge. High, reduced synthesis cycle, excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In the specific implementation process, the hydrothermal synthesis method of lithium manganese iron phosphate solid solution of the present invention, the specific steps are as follows:

[0040] (1) Synthesis of lithium manganese iron phosphate solid solution: under stirring, lithium hydroxide monohydrate is added to deionized water or distilled water, then phosphoric acid solution is added dropwise, then ferrous sulfate heptahydrate, manganese sulfate monohydrate and Antioxidant ascorbic acid (the molar ratio of lithium hydroxide monohydrate, phosphoric acid, ferrous sulfate heptahydrate, manganese sulfate monohydrate and antioxidant ascorbic acid is (2.5~3.5):(0.5~1.5):(0.1~1.2):(0.1~ 1.2): (0.001~0.01)), heating the mixed solution to 140~200℃ under microwave heating for 5~60min under stirring state, and preparing lithium manganese iron phosphate solid solution, followed by solid-liquid separation to obtain off-white precipitate ferromanganese phosphate lithium.

[0...

Embodiment 1

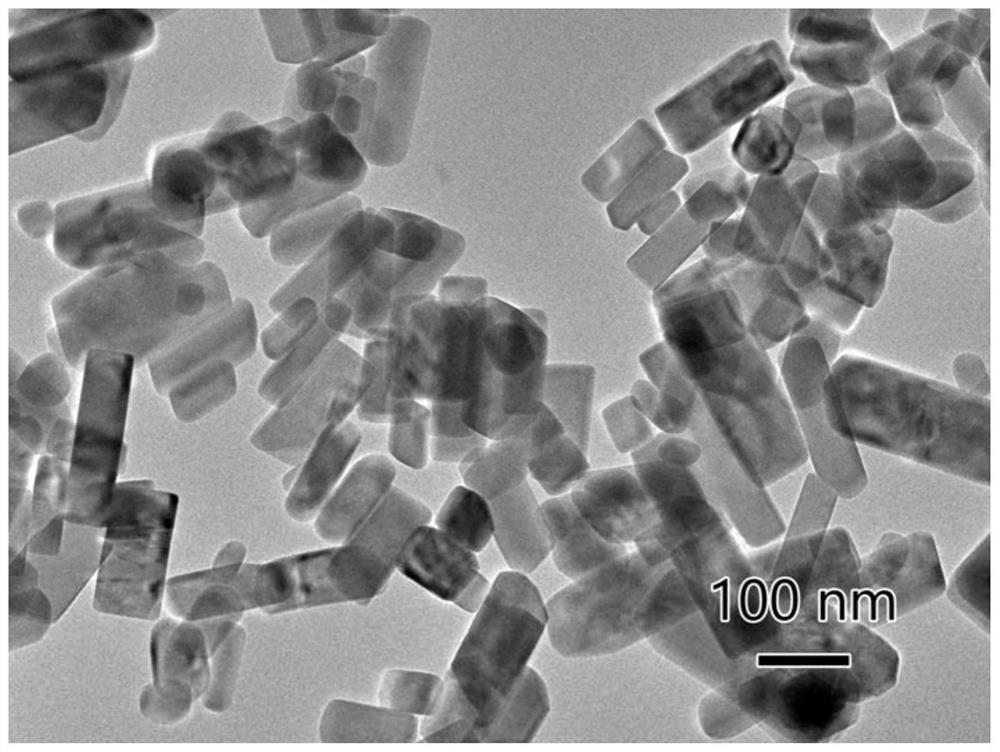

[0053] In this example, pure deionized water was used as the reaction solvent by the hydrothermal method, and nanorod-shaped LiFe was prepared by microwave stirring and heating. 0.5 mn 0.5 PO 4 solid solution. The lithium source is neutralized with lithium hydroxide monohydrate and phosphoric acid to generate lithium phosphate in the reactor, the iron source is ferrous sulfate heptahydrate, the manganese source is manganese sulfate monohydrate, and the antioxidant is ascorbic acid.

[0054] The specific method of hydrothermal synthesis is: take a polytetrafluoroethylene tank as a reaction kettle, get 9.2g of lithium hydroxide monohydrate and add it to 55mL of deionized water under stirring, then add 5.14mL of phosphoric acid (concentration 85wt%), 10.04 g ferrous sulfate heptahydrate, 6.1038 g manganese sulfate monohydrate and 0.2 g ascorbic acid. After being stirred evenly, it was quickly transferred to a microwave heating workstation, and heated to 180°C for 14 minutes un...

Embodiment 2

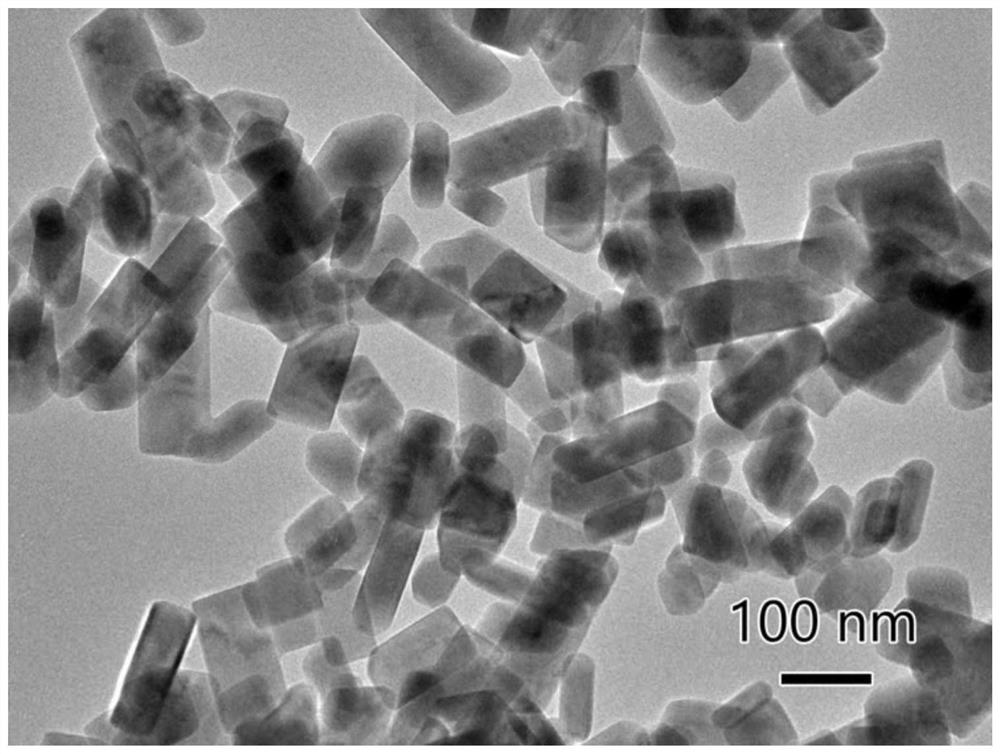

[0058] The difference from Example 1 is that the reaction time used in the experiment is different, and the nanorod-shaped LiFe 0.5 mn 0.5 PO 4 ( Figure 10 ). In this embodiment, the lithium source adopts lithium hydroxide monohydrate and phosphoric acid to be added in the reaction kettle successively, in the reaction kettle, lithium phosphate is generated through neutralization reaction, the iron source adopts ferrous sulfate heptahydrate, and the manganese source adopts manganese sulfate monohydrate, The antioxidant uses ascorbic acid.

[0059] The solution used was pure deionized water. The hydrothermal conditions are: temperature 180°C, time 5min.

[0060]The specific method of the carbon coating method is as follows: first rinse the synthesized lithium manganese iron phosphate solid solution with water, and then rinse it with alcohol; then, mix the carbon source and the lithium manganese iron phosphate solid solution at a mass ratio of 1:4, and put them into the tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com