Enhanced heat radiation paint, application thereof and radiation heat exchange device using the same

A technology of radiative heat exchange and thermal radiation, applied in the field of radiative heat exchange, can solve the problems of low cooling capacity of metal radiant panels, condensation of metal radiant panels, loss of viscosity of thermally conductive adhesives, etc., to increase absorption rate and emissivity, and increase temperature The effect of uniformity and high cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

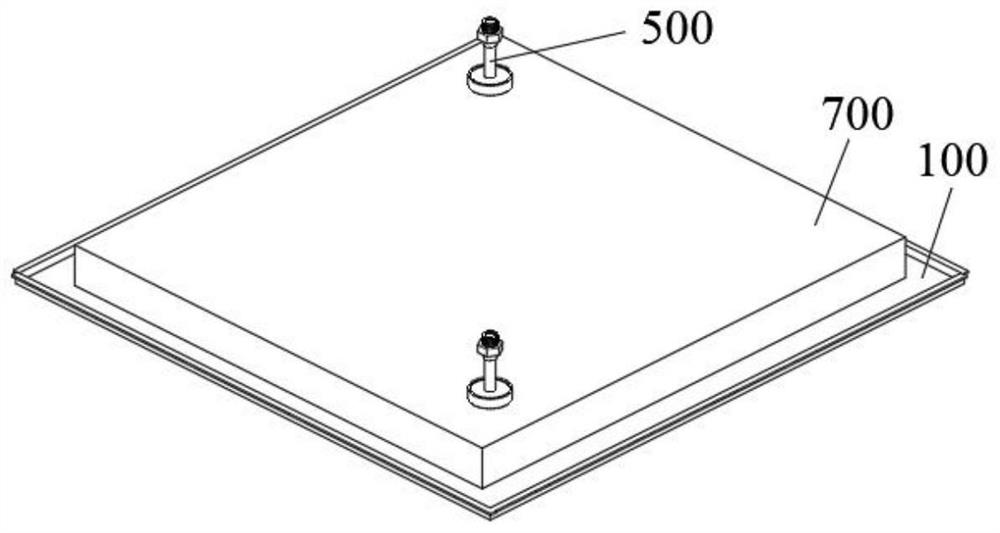

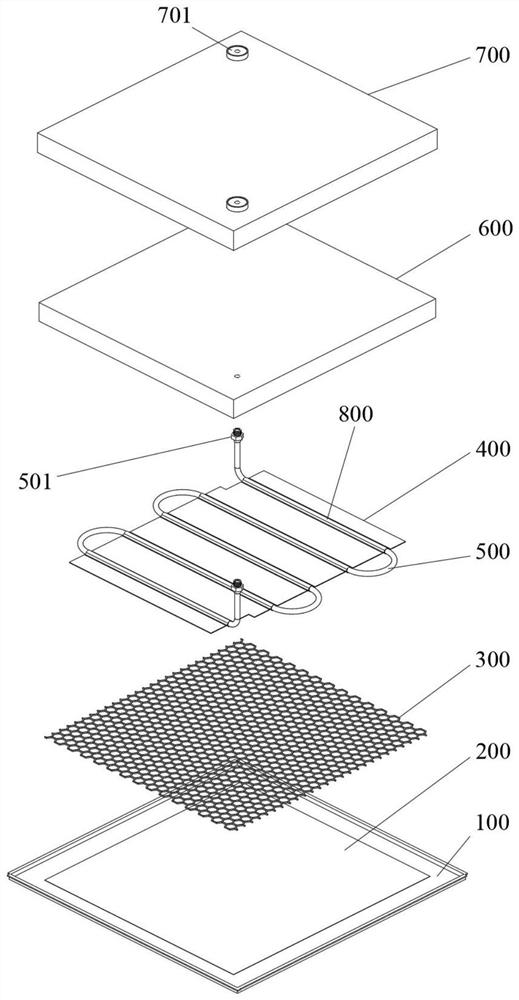

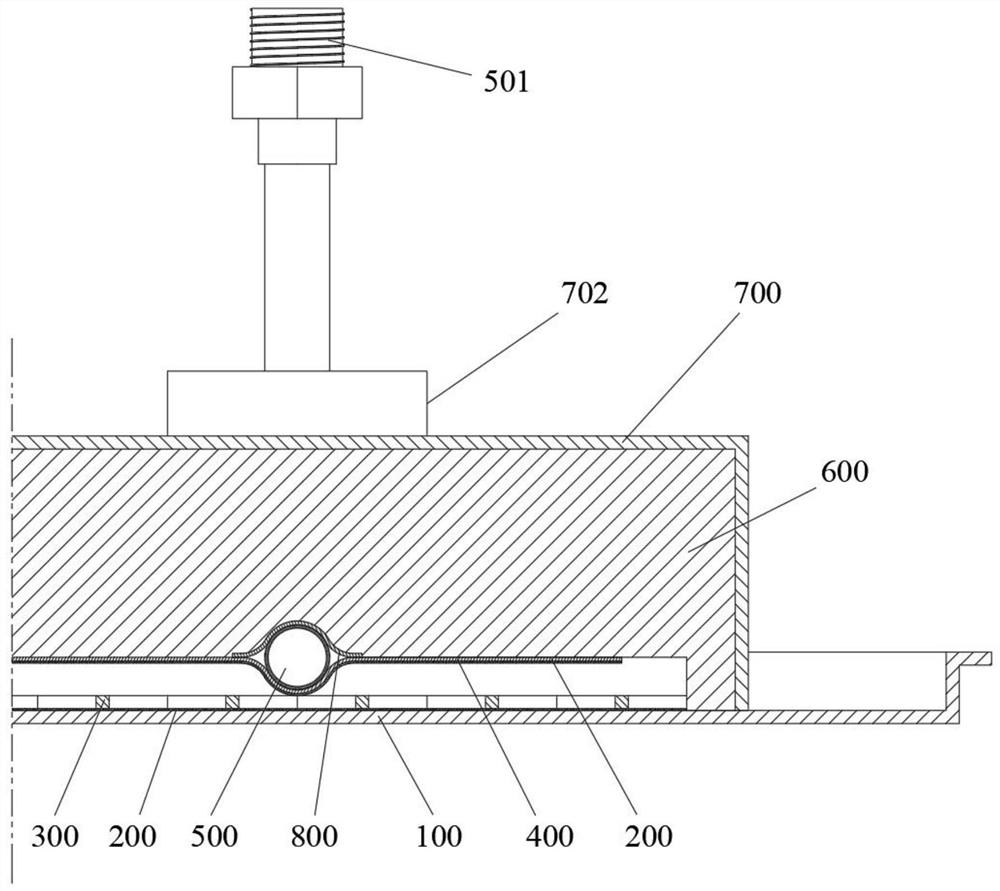

[0024] Such as Figure 1 to Figure 4 As shown, this embodiment provides a radiation heat exchange device, including a first metal radiant plate 100, a second metal radiant plate 400, and a heat transfer channel 500; the second metal radiant plate 400 is in contact with the heat transfer channel 500 and Together form a heat exchange core plate; the first metal radiant plate 100 is provided with a first radiation heat exchange area on the side close to the heat exchange core plate; the first radiation of the heat exchange core plate and the first metal radiant plate 100 The heat exchange area corresponds to and is placed in parallel with an interval. The minimum distance between the heat exchange core plate and the first metal radiation plate is 2 mm; the heat exchange core plate is on the side surface close to the first metal radiation plate 100 and Surfaces of the first radiation heat exchange area are all provided with a thermal radiation enhancing coating 200 .

[0025] In ...

Embodiment 2

[0037] The enhanced thermal radiation coating that forms the enhanced thermal radiation coating of Example 1 is prepared from reinforcing material components, black material components and binders; specifically, it consists of 2.5 parts by mass of silicon powder, 2.5 parts Parts of boron powder, 2 parts of carbon black, 2 parts of manganese dioxide, 6 parts of iron oxide black, 30 parts of styrene / n-butyl acrylate / isopropyl acrylate copolymer, 37 parts of xylene, Prepared from 12 parts of 1,2-dichloroethane and 6 parts of n-butyl acetate, wherein the molar ratio of styrene, n-butyl acrylate, and isopropyl acrylate is 5:3:1.

[0038] In the enhanced heat radiation coating of this embodiment, the powder of the reinforcing material component and the powder of the black material component can be uniformly dispersed in the binder component. When in use, it is coated on the surface of the metal material to form an enhanced heat radiation coating When the coating is combined with met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com