A commercial method for rapid humification and return of straw in situ

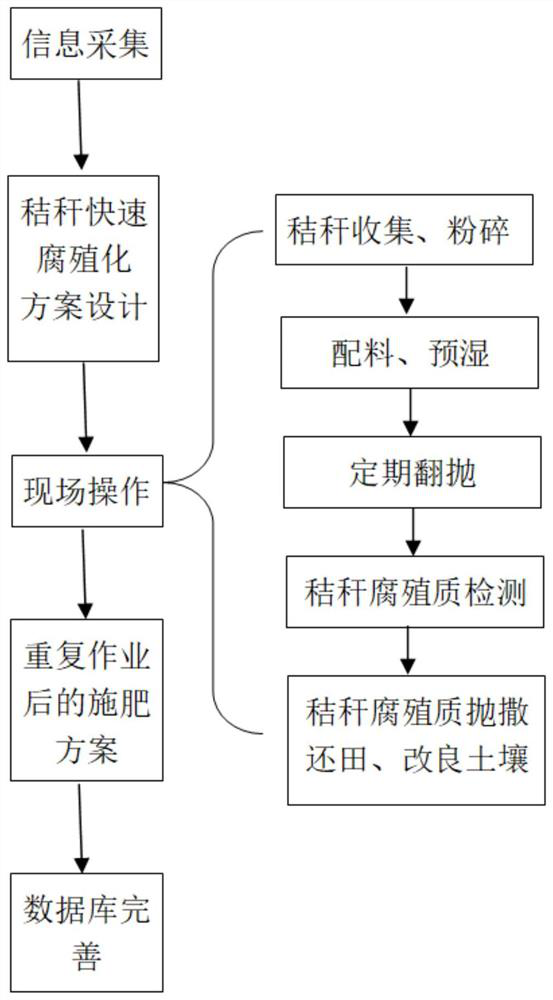

A humification and straw technology, which is applied in the field of agricultural waste resource utilization and environmental protection, can solve the problems of unsustainable utilization of straw as fertilizer, increased production and use costs of organic fertilizers, and insufficient benefits to cover fertilization costs. , to achieve the effect of benefiting crop growth and maintaining ecology, reducing transportation distance and transportation costs, and saving storage and processing sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] Test location and time: Dongri New Village, Chang'an Town, Fujin City, Heilongjiang Province, the field straw was quickly humified in the winter of 2018, and the straw humus was sown in the spring of 2019;

[0116] Test categories and varieties: straw crops: corn (Jidong 56), straw humus crops to be applied: corn (Jidong 56);

[0117] Experimental procedure:

[0118] 1) Straw collection and crushing: collect corn stalks and crush them to less than 5cm;

[0119] 2), batching, pre-wetting: mix the straw and high-nutrition priming agent evenly, the effective C / N of the corn stalk rapid humification mixture in this embodiment is 25:1, add water to adjust the moisture to 60wt%, and mix and pre-wet Afterwards, piles are built for fermentation, and the pile is built into a trapezoidal stack with a width of 5 meters, a height of 2.5 meters, and a length of 10 meters;

[0120] Wherein, the high-nutrition priming agent comprises the following steps to prepare:

[0121] ① Prepa...

Embodiment 2

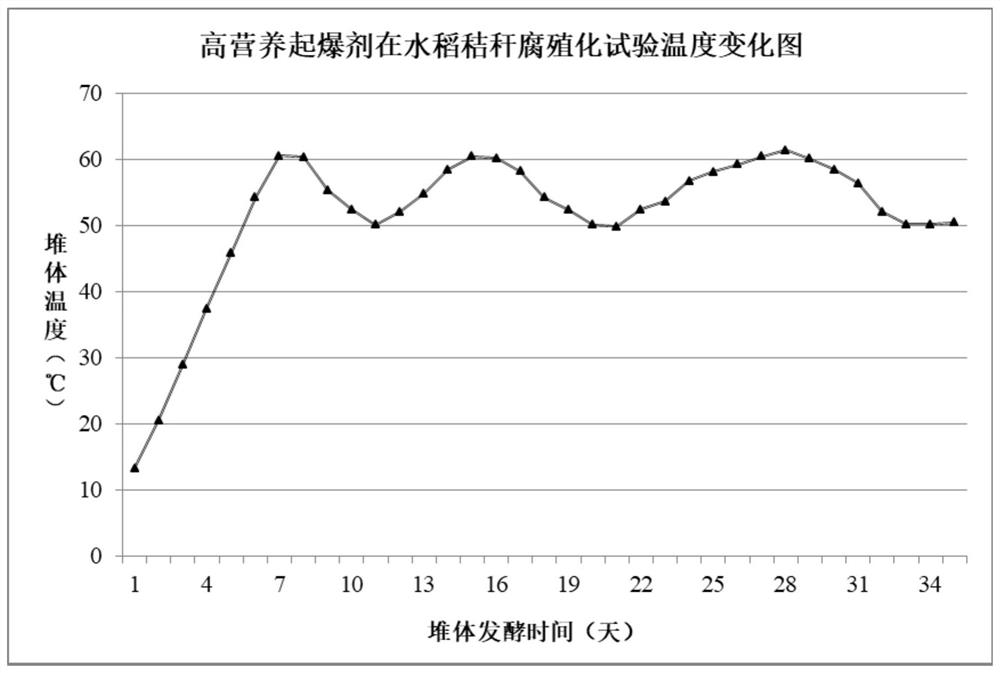

[0140] Test location and time: Chahe Village, Chahe Town, Hongze District, Huaian City, Jiangsu Province, rapid humification of straw in spring 2019, and straw humus transplanting in summer;

[0141] Test categories and varieties: straw crops: rice (Nanjing 9108), straw humus crops to be applied: rice (Nanjing 9108);

[0142] Experimental procedure:

[0143] 1) Straw collection and crushing: collect rice straw and crush it to less than 5cm;

[0144] 2), batching, pre-wetting: mix the straw and the high-nutrition priming agent evenly, the effective C / N of the rapid humification mixture of rice straw in this embodiment is 20:1, add water to adjust the moisture to 60wt%, and mix and pre-wet Afterwards, piles are built for fermentation, and the pile is built into a trapezoidal stack with a width of 5 meters, a height of 2.5 meters, and a length of 10 meters;

[0145] Wherein, the high-nutrition priming agent comprises the following steps to prepare:

[0146] ① Preparation of cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com