Integrated membrane electrode and preparation method and application thereof

A membrane electrode and powder technology, applied in the direction of electrodes, electrode shape/type, diaphragm, etc., can solve the problems of low current density, poor stability, high cost of combined membrane electrodes, etc., and achieve the goal of increasing current density and reducing electrolysis energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

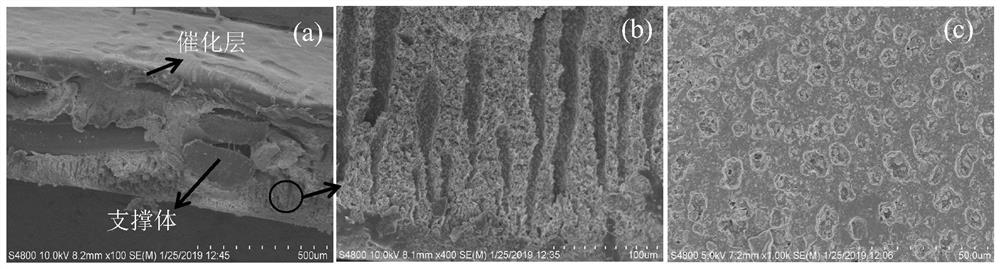

[0060] The present invention also relates to the preparation method of the above-mentioned integrated membrane electrode, comprising coating the catalyst slurry on the surface of the uncured and formed composite membrane body to form a catalyst layer body, and then obtaining the integrated porous composite membrane and porous catalyst layer by a phase inversion method oxidized membrane electrodes.

[0061] In one embodiment of the present invention, the above-mentioned preparation method comprises the following steps:

[0062] S1 Preparation of composite membrane material and catalyst slurry: mix inorganic powder, polysulfone, and the first solvent uniformly in a certain proportion, and obtain a uniform composite membrane material after filtration and defoaming; mix catalyst, polysulfone, and ion exchange resin Mix evenly with the second solvent in a certain proportion, and obtain a uniform catalyst slurry after filtering and defoaming;

[0063] S2 Prepare the membrane electr...

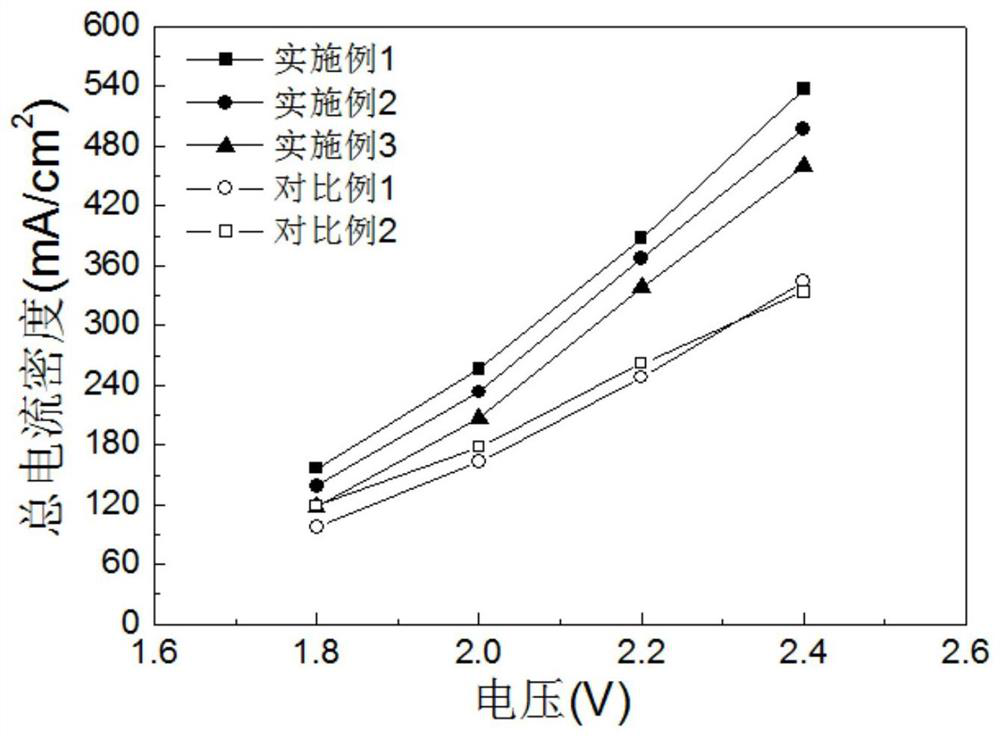

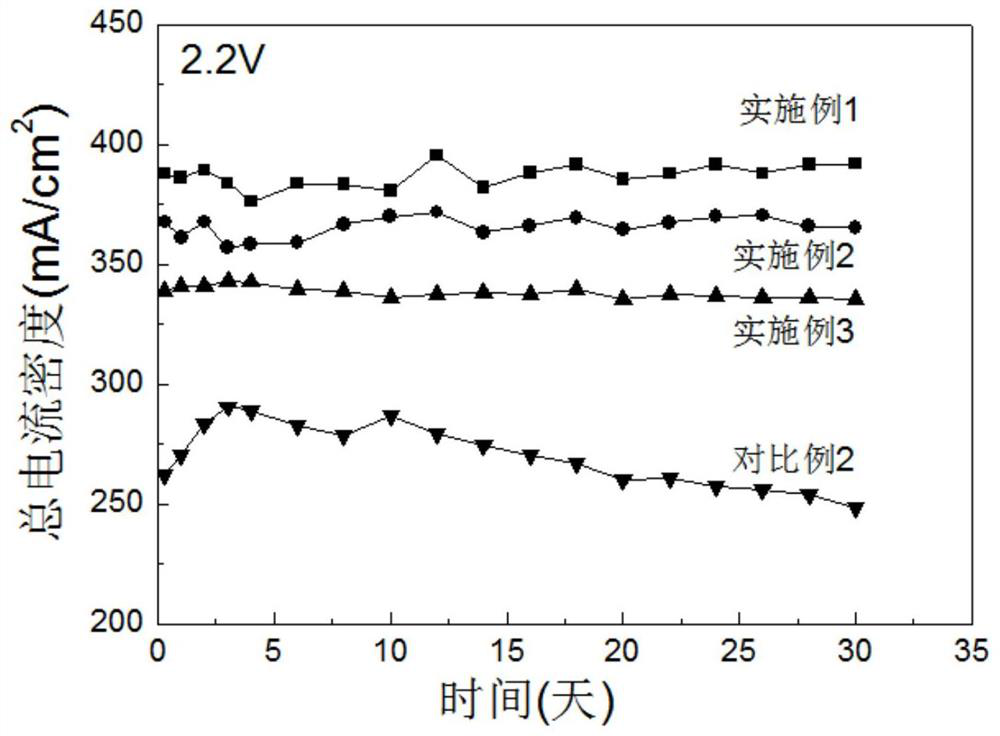

Embodiment 1

[0076] 1) Preparation of composite membrane material and catalyst slurry: Weigh 50g of ZrO in a mass ratio of 3:1:4.8 2 Powder (particle size is 50nm), 16.67g of polyarylsulfone and 80g of 1-methyl-2-pyrrolidone in a ball mill jar, add 500g of zirconia balls, ball mill for 48h to obtain a homogeneous mixture, then filter and vacuumize it The composite film material is obtained by removing air bubbles. Using NiO powder (100nm) as the anode catalyst, weigh 8.3g of NiO powder and ultrasonically disperse it in 12g of 1-methyl-2-pyrrolidone, add 1.2g of polysulfone, stir mechanically for 24h, filter and remove in a vacuum Bubbles, resulting in a homogeneous catalyst slurry.

[0077] 2) Prepare the membrane electrode blank: fix the polyphenylene sulfide braided mesh with a thickness of 0.3 mm and a mesh number of 50 on the surface of the glass plate in parallel, cast the composite membrane material onto the surface of the polyphenylene sulfide braided mesh, and control the liquid c...

Embodiment 2

[0081] Composite film material is prepared in the same way as in Example 1; 2 o 3 Powder (300nm) is used as anode catalyst, takes by weighing 15g of Fe 2 o 3 The powder was ultrasonically dispersed in 18 g of 1-methyl-2-pyrrolidone, 3.05 g of polysulfone was added, mechanically stirred for 24 hours, filtered and vacuumed to remove air bubbles to obtain a uniform catalyst slurry. The membrane electrode body is prepared in the same way as in Example 1, and solidified by a coagulation bath to obtain a Fe-containing 2 o 3 The integrated membrane electrode of the porous catalytic layer, the thickness of the membrane electrode is 0.66mm, and the Fe in the porous catalytic layer 2 o 3 Powder loading is 36mg / cm 2 .

[0082] Put the above membrane electrode into the alkaline electrolysis water hydrogen production electrolysis cell, containing Fe 2 o 3 The porous catalytic layer of the catalyst is used as the anode catalytic layer near the anode side, the nickel mesh is used as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com