Enhanced magnetic adsorbent

A magnetic adsorbent, enhanced technology, applied in adsorption water/sewage treatment, other chemical processes, special treatment targets, etc., can solve the problems of less chitosan after cross-linking, poor dye adsorption performance, etc., and achieve grafting. High efficiency, good adsorption effect, and the effect of reducing adsorption cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An enhanced magnetic adsorbent is prepared through the following steps:

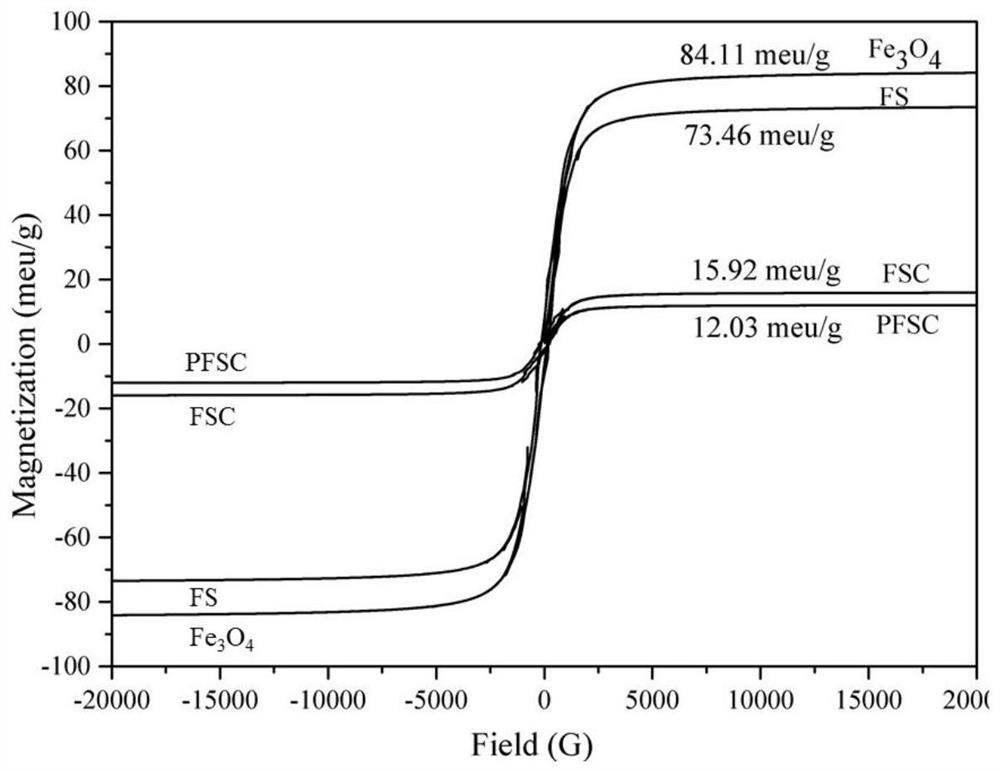

[0028] S1, preparation of Fe 3 o 4 @SiO 2 Nanoparticles (FS): 1.2 g Fe 3 o 4 Add magnetic nanoparticles into 600 mL ethanol, ultrasonically disperse for 10–15 min, then add 13 mL ammonia solution and 200 mL distilled water into a 1000 mL glass beaker, ultrasonically disperse for 40 min, then add 6 mL TEOS dropwise, and Stir for 8 h; after the reaction, wash with ethanol and distilled water for 3 times, pour into an evaporating dish, and dry in vacuum for 4 h to obtain SiO 2 Coated Fe 3 o 4 magnetic nanoparticles.

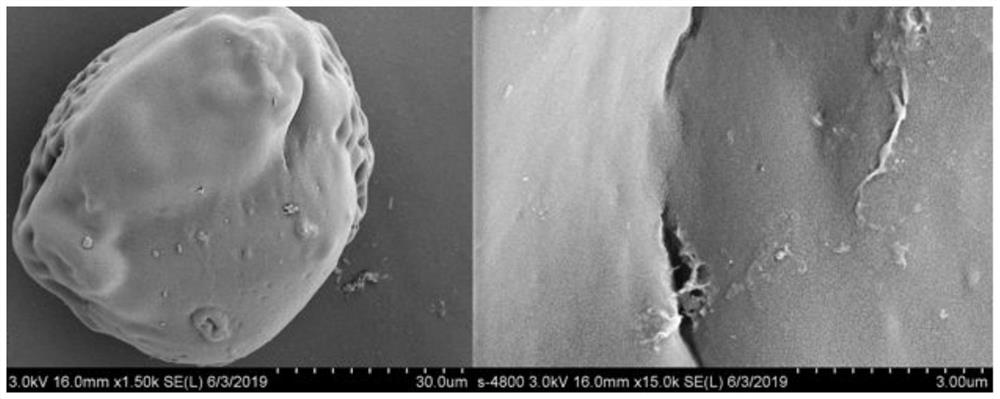

[0029] S2. Preparation of magnetic chitosan microspheres (FSC): First, 7.5 g chitosan was dissolved in 200 mL of 1% acetic acid solution to prepare a chitosan solution with a mass fraction of 3.75%, and stirred for 1 h. Add 3.5 g of Fe obtained in step S1 to the above chitosan solution 3 o 4 @SiO 2 Nanoparticles were stirred to obtain a suspension, which was dispersed in a mi...

Embodiment 2

[0033] The difference between the preparation method in this example and Example 1 is that the mass of initiator VA-044 in step S3 is 0.0275 g, and the volume of AO monomer is 5 mL. The obtained enhanced magnetic adsorbent is denoted as PFSC1.

Embodiment 3

[0035] The difference between the preparation method in this example and Example 1 is that the mass of initiator VA-044 in step S3 is 0.0775 g, and the volume of AO is 15 mL. The obtained enhanced magnetic adsorbent is denoted as PFSC3.

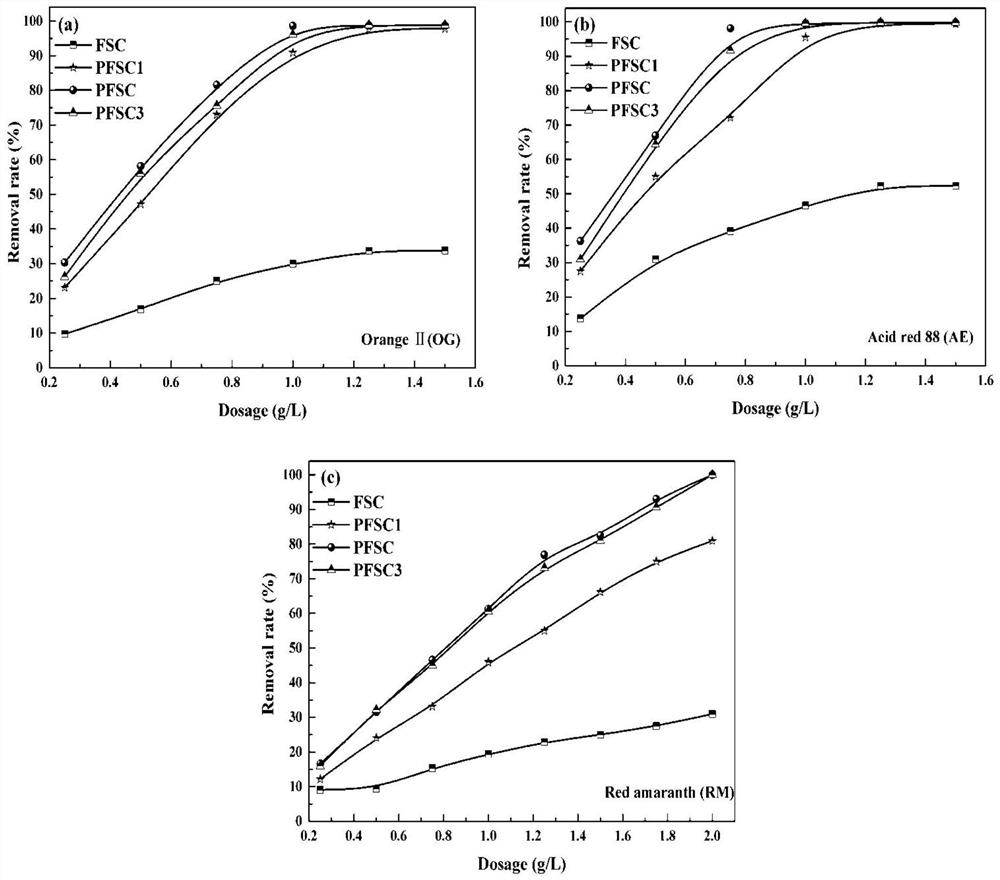

[0036] 2. Adsorption performance test.

[0037] 1. The effect of dosage on the removal of dye.

[0038] Prepare 1000mg / L orange II (OG), 1000mg / L acid red 88 (AE) and 800mg / L amaranth (RM) solutions, and adjust the pH of the solution to 7.0. Take 25 mL of each solution in the Erlenmeyer flask, and conduct three parallel experiments. One group is added with PFSC adsorbent material, the other group is added with PFSC1 adsorbent material, and the third group is added with PFSC3 adsorbent material. The dosage of adsorbent is 0.25 g / L , 0.5 g / L , 0.75 g / L , 1.0. g / L , 1.25 g / L , 1.5 g / L, put the Erlenmeyer flask in a constant temperature water bath shaking box at 25 ° C, and measure it in the Erlenmeyer flask after 24 hours solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com