Modified copper-zinc-aluminum catalyst suitable for AWS reaction as well as preparation method and application of modified copper-zinc-aluminum catalyst

A copper-zinc-aluminum catalyst and modification technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, heterogeneous catalyst chemical elements, etc., can solve the problem of low activity and achieve simple equipment, easy large-scale production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

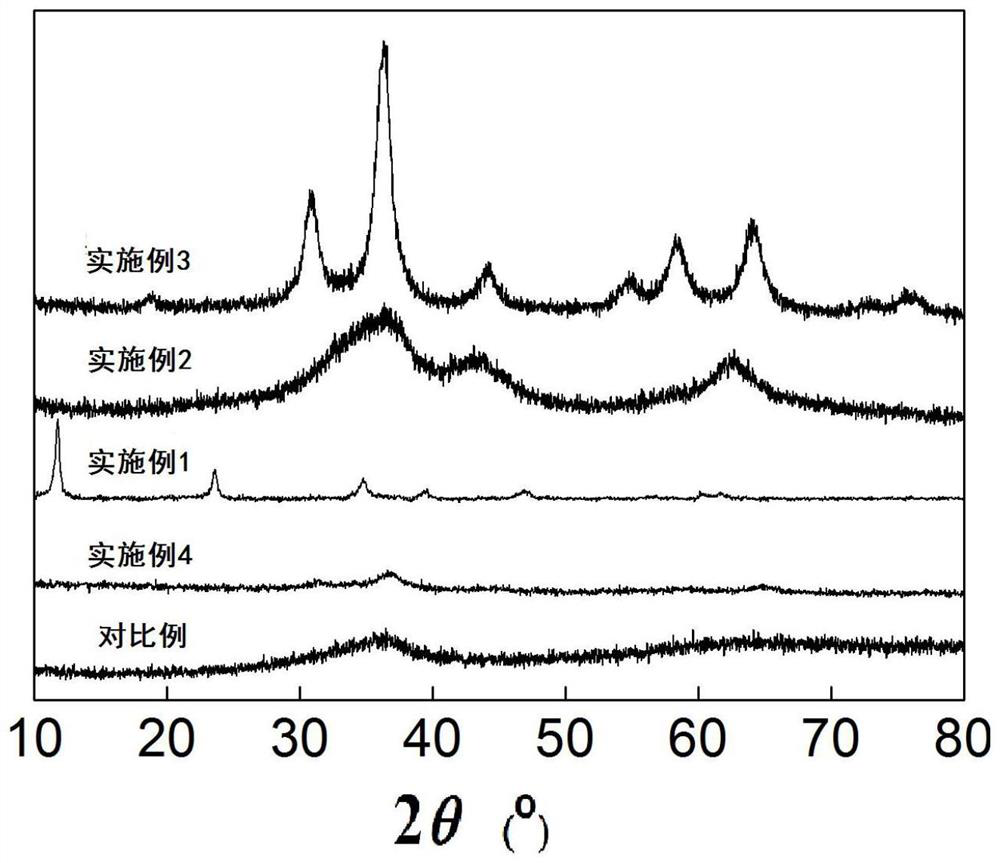

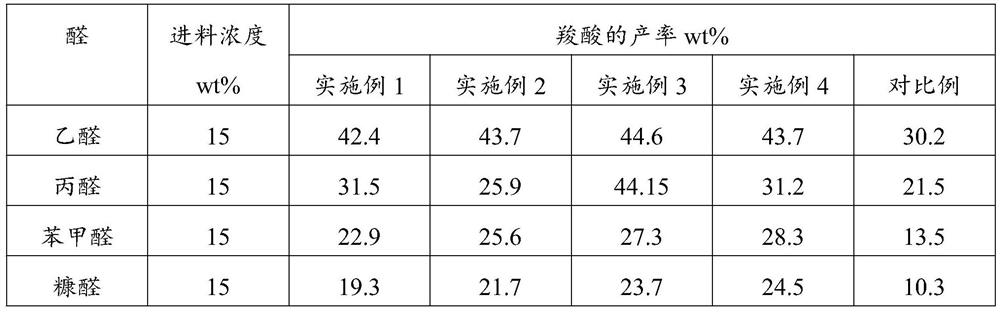

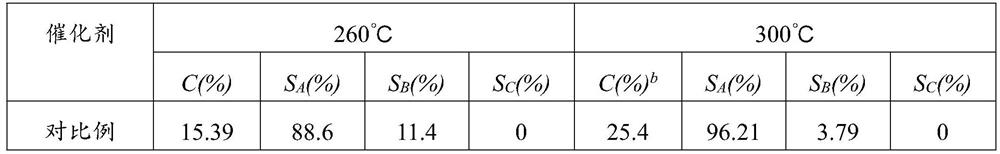

Examples

preparation example Construction

[0049] In a preferred embodiment, the above-mentioned method for preparing an X-Cu-Zn-Al catalyst applied to the oxidation of aldehydes into carboxylic acids comprises the following steps:

[0050] Step 1: Take a certain amount of nitric acid X, copper nitrate, zinc nitrate and aluminum nitrate respectively, dissolve these nitrates in an appropriate amount of distilled water to make a nitrate solution; weigh a certain amount of sodium hydroxide and sodium carbonate to prepare into a mixed aqueous solution of sodium hydroxide and sodium carbonate as a precipitating agent;

[0051] Step 2: Slowly add the prepared precipitant solution drop by drop to X by co-precipitation method 2+ 、Cu 2+ , Zn 2+ 、Al 3+ In the nitrate mixed solution, until the mixed solution reacts completely, stir rapidly at the same time;

[0052] Step 3: During the whole dropping process, the pH of the solution is controlled to be about 9, and the temperature is controlled at about 50°C, then stirred at co...

Embodiment 1

[0070] Prepare Mg-doped copper-zinc-aluminum catalyst, the process is as follows:

[0071] (1) Weigh 1.2g of copper nitrate, 3g of zinc nitrate hexahydrate, 3.7g of aluminum nitrate nonahydrate, and 0.2g of magnesium nitrate, add them into 30mL of water to make a mixed aqueous solution, prepare 2.4g of sodium hydroxide and 3g of sodium carbonate and add them to 30mL of water A mixed solution of sodium hydroxide and sodium carbonate was used as a precipitating agent.

[0072] (2) Put the mixed aqueous solution in a constant temperature water bath, control the temperature to 50°C, add the mixed aqueous solution of sodium hydroxide and sodium carbonate to the mixed aqueous solution at a rate of 1 drop per second, and stir at a speed of 450rpm at the same time until the pH is 9 , continue to stir at a speed of 450rpm for 1h, let stand for 4h aging, and obtain a precipitate.

[0073] (3) Suction filter the precipitate, wash with water, dry at 110°C for 12h, put it into a muffle fu...

Embodiment 2

[0075] Prepare Ni-doped copper-zinc-aluminum catalyst, the process is as follows:

[0076] (1) Take by weighing 4.8g copper nitrate, 6g zinc nitrate hexahydrate, 7.5g aluminum nitrate nonahydrate, 4.8g nickel nitrate, add 80% water, be mixed with mixed aqueous solution, prepare 6g sodium hydroxide and 8g sodium carbonate and add in 150mL water A mixed solution of sodium hydroxide and sodium carbonate was used as a precipitating agent.

[0077] (2) The mixed aqueous solution is placed in a constant temperature water bath, the pH is controlled to be 9, and the temperature is 50 ° C. The mixed aqueous solution of sodium hydroxide and sodium carbonate is added in the mixed aqueous solution at a rate of 1 drop per second, while stirring at a speed of 500 rpm. Continue to stir at 500 rpm for 1 h until the reaction is complete, and let stand for 4 h to age to obtain a precipitate.

[0078] (3) Suction filter the precipitate, wash it with water, dry it at 110°C for 12h, put it into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com