Method for preparing porous boric acid with coral structure

A technology of boric acid and coral, which is applied in the field of preparation of porous boric acid with coral structure, can solve the problems that it is difficult to meet the requirements of boric acid surface reactivity, high specific surface area and porosity, and achieve the effect of low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

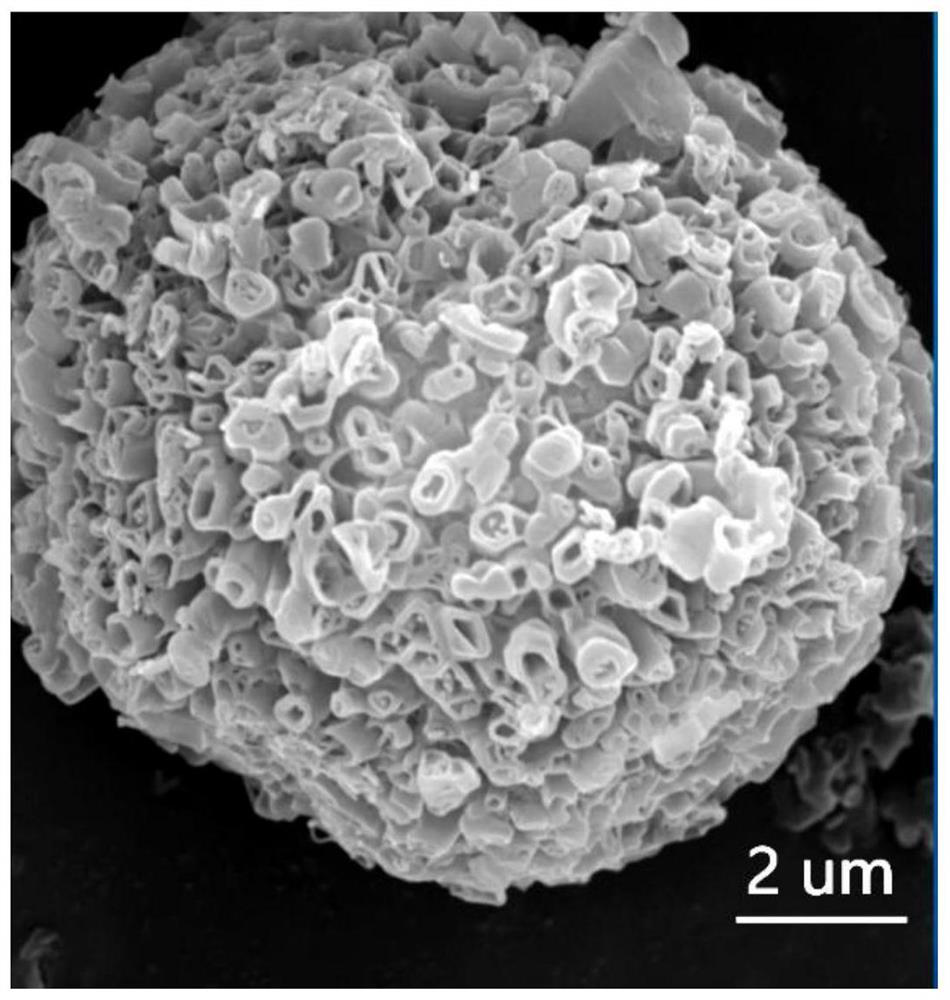

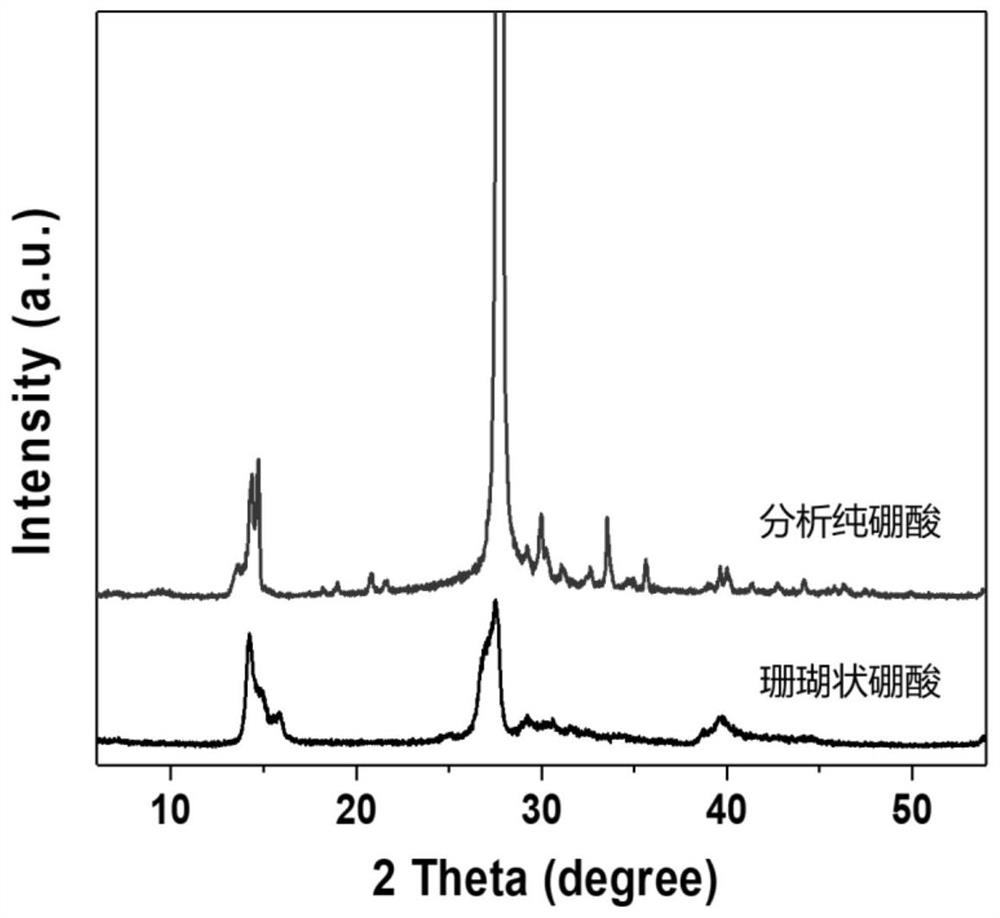

[0025] Add 80g of analytically pure boric acid into a pressure vessel equipped with 100g of mixed liquid solvent, wherein the mixed liquid solvent is prepared by ethanol, glycerol and water according to the above formula ratio; heat the pressure vessel to make the temperature reach 150°C to obtain a clear solution; then control the cooling rate 3-5°C / min, let the temperature drop to 20°C, let it stand for 1 hour, then raise it to 30-40°C at a heating rate of 2°C / min, let it stand for 30 minutes, then cool down to room temperature naturally, a large amount of white crystal liquid can be obtained, the Suction filter the feed liquid, and dry at 60°C to obtain coral-like porous boric acid powder, whose appearance is as follows: figure 1 shown; the X-ray diffraction pattern of the obtained powder is shown in figure 2 , which is in line with the standard card JCPDS No.30-0199 after analysis; the corresponding equilibrium adsorption curve is as follows image 3 It is shown that it ...

Embodiment 2

[0027] Add 30g of analytically pure boric acid into a pressure vessel containing 10g of a mixed solution solvent, wherein the mixed solution solvent is prepared from methanol, isopropanol and water according to the above formula ratio; heat the pressure vessel until the temperature reaches 80°C to obtain a clear solution; then control the cooling rate 2-3°C / min, let the temperature drop to 20°C, let it stand for 1 hour, then raise it to 40°C at a rate of 2-4°C / min, let it stand for 30 minutes, then cool down to room temperature naturally, a large amount of white crystal liquid can be obtained, the The feed liquid is suction filtered and dried at 60°C to obtain rich tubular porous coral structure boric acid, whose appearance is as follows: Figure 4 shown.

Embodiment 3

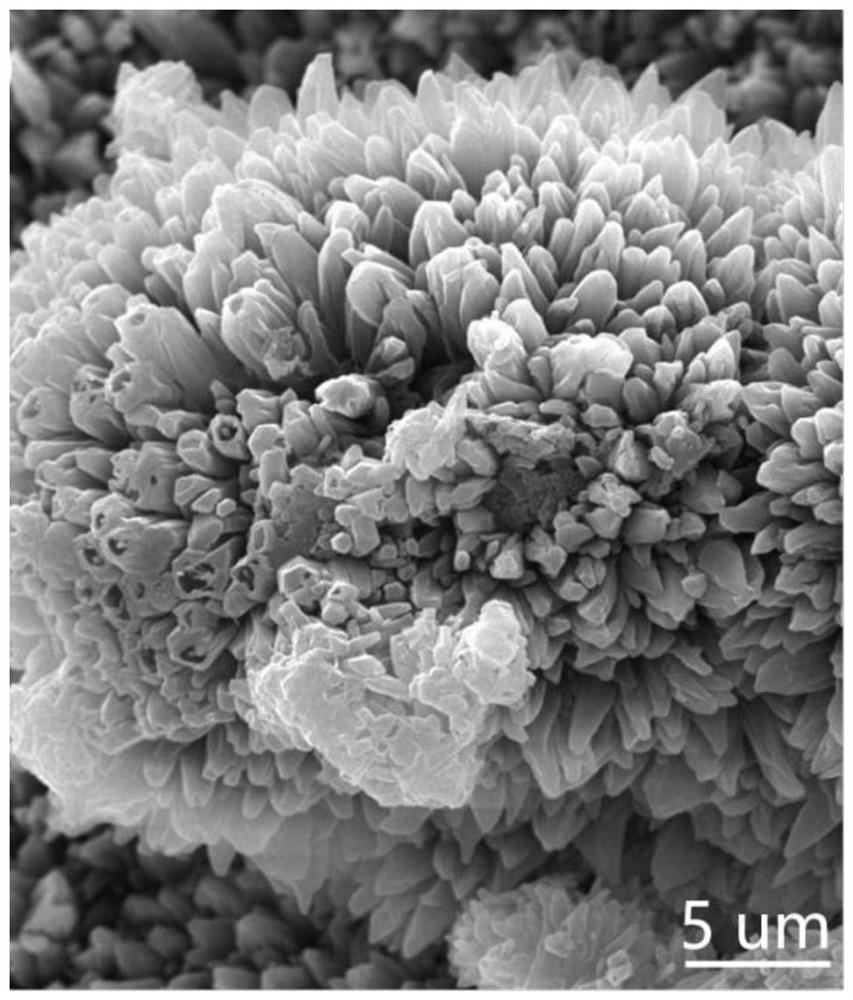

[0029] Add 45g of analytically pure boric acid into a pressure vessel equipped with 100g of mixed liquid solvent, wherein the mixed liquid solvent is prepared by ethanol, n-butanol and water according to the above formula ratio; heat the pressure vessel so that the temperature reaches 110°C to obtain a clear solution; then control the cooling rate 3-5°C / min, let the temperature drop to 5°C, stand for 1h, then increase the temperature at a rate of 3-5°C / min to 40°C for 1h, then cool naturally to room temperature, a large amount of white crystal solution can be obtained, the solution After suction filtration and drying at 60°C, the loose coral porous boric acid powder can be obtained, and its appearance is as follows: Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com