Solid catalyst component of olefin polymerization catalyst, preparation method thereof, olefin polymerization catalyst and olefin polymerization method

A solid catalyst and olefin polymerization technology, applied in the field of olefin polymerization, to achieve the effect of low fine powder content, good regularity and good regularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] According to a second aspect of the present invention, the present invention provides a method for preparing a solid catalyst component of an olefin polymerization catalyst, the preparation method comprising:

[0064] (1) In the presence of an inert solvent, the catalyst component A, an aluminum alkyl and an external electron donor compound are subjected to a contact reaction; the catalyst component A contains titanium, magnesium, chlorine and an internal electron donor compound;

[0065] (2) adding α-olefin to the reaction system obtained in step (1) to carry out the first polymerization reaction;

[0066] (3) Adding ethylene to the reaction system obtained in step (2) to carry out the second polymerization reaction.

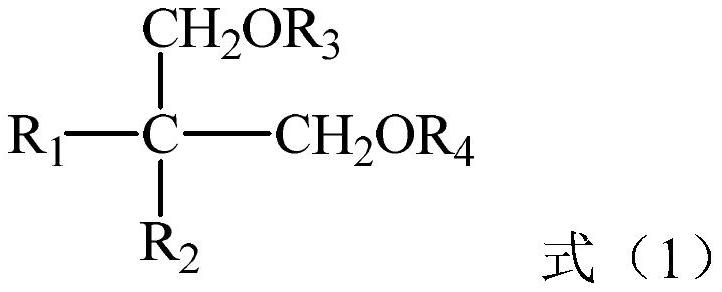

[0067] In the preparation method of the present invention, the internal electron donor compound includes a 1,3-diether compound, and the structure of the 1,3-diether compound is shown in formula (1):

[0068]

[0069] Among them, R 1 and R 2 each i...

preparation example 1

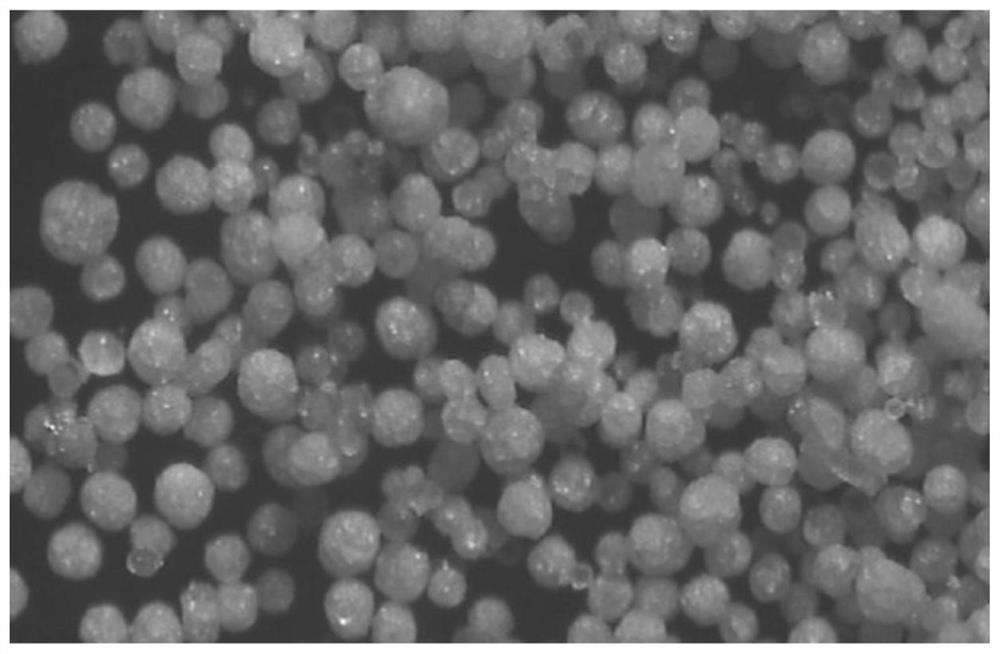

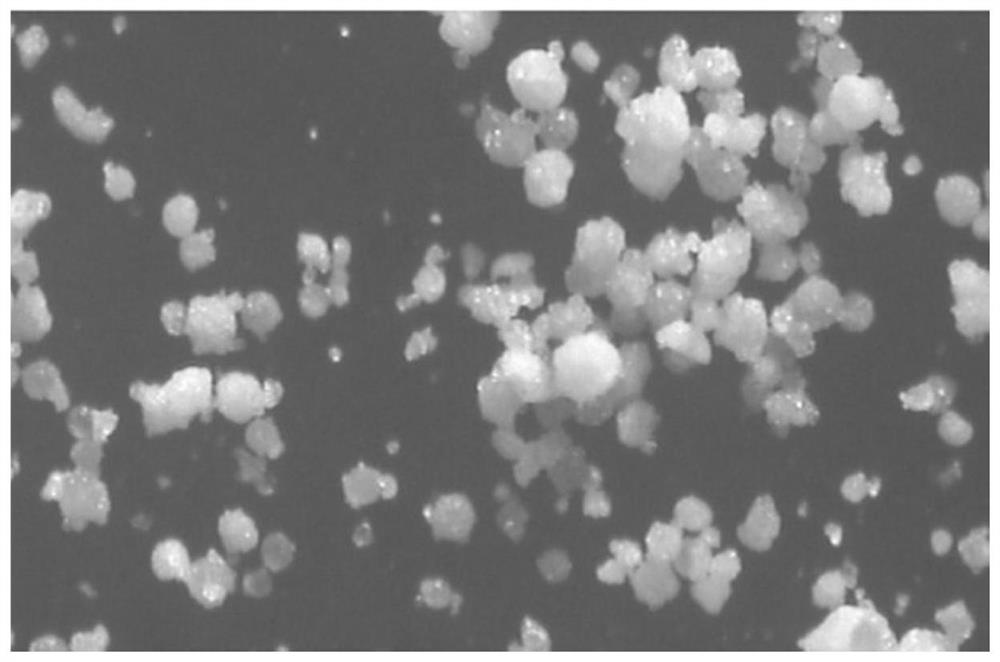

[0101]Add 1.1L of titanium tetrachloride to a stirred 3L glass reaction bottle and cool down to -20°C, then add 100g of magnesium chloride alcoholate spherical carrier [Mg(C 2 h 5 Oh) 2.6 ] (average particle size D50=45μm, the same below), after reacting at -20°C for 0.5 hours, slowly raise the temperature to 120°C, add 15g of 2-isopropyl-2-isopentyl-1,3-di Methoxypropane and 0.6g tributyl phosphate were reacted at 120°C for 0.5 hours, the liquid was filtered off, 1L titanium tetrachloride was added, and the liquid was filtered off at 120°C for 2 hours to obtain a solid product. The obtained solid product was washed 5 times with hexane, and finally vacuum-dried to obtain catalyst component A (average particle size D50=40 μm), denoted as A1.

preparation example 2

[0103] Add 1.2L of titanium tetrachloride to a stirred 3L glass reaction bottle and cool down to -20°C, then add 100g of magnesium chloride alcoholate spherical carrier [Mg(C 2 h 5 Oh) 2.6 ], after reacting at -20°C for 0.5 hours, slowly raise the temperature to 120°C, add 15g of 2-isopropyl-2-isopentyl-1,3-dimethoxypropane during the heating process, and then at 120°C React for 0.5 hours, filter off the liquid, add 1L of titanium tetrachloride, and maintain at 120°C for 2 hours, then filter off the liquid to obtain a solid product, wash the obtained solid product with hexane for 5 times, and finally dry it in vacuum to obtain a catalyst Component A (average particle size D50=40 μm) is denoted as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com