Fullerene-based Fe and N-doped porous carbon material as well as preparation method and application thereof

A technology based on fullerene and fullerene derivatives, which is applied in the direction of fuel cell half-cells and primary battery half-cells, structural parts, electrical components, etc. The electrocatalytic oxygen reduction performance is backward, the half-wave potential is low, and there is no innovation, etc., to achieve the effect of good regularity, excellent uniformity, and moderate size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

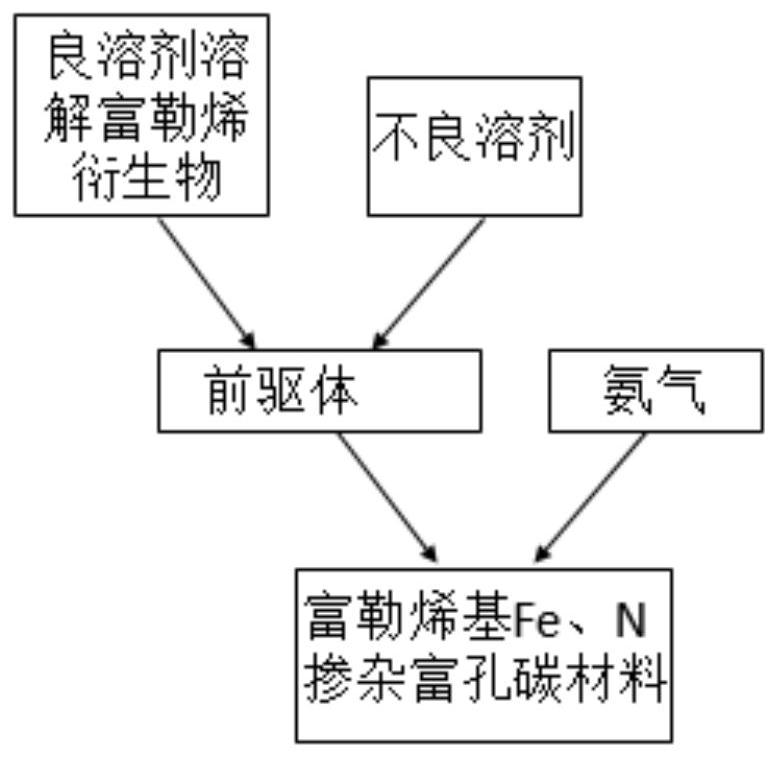

[0033] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing a fullerene-based Fe, N-doped porous carbon material, the method comprising the following steps:

[0034] S1 Use benzene solvent as a good solvent to dissolve the fullerene derivative, then mix it with an alcohol solvent as a poor solvent, let it stand at room temperature for 12 to 24 hours, then filter to obtain the precipitate, and dry the precipitate under vacuum for 8 Hours to 12 hours to prepare the precursor; among them, the solubility of fullerene molecules can be reduced by mixing a good solvent and a poor solvent in which fullerene molecules are dissolved. Under the action of van der Waals force, fullerene molecules self-assemble to form Micro-nano structure with three-dimensional hierarchical growth;

[0035]S2 In an ammonia atmosphere, the precursor is calcined at 600 ° C to 800 ° C for a preset time, so that the phase transition of the fullerene crystal occurs...

Embodiment 1

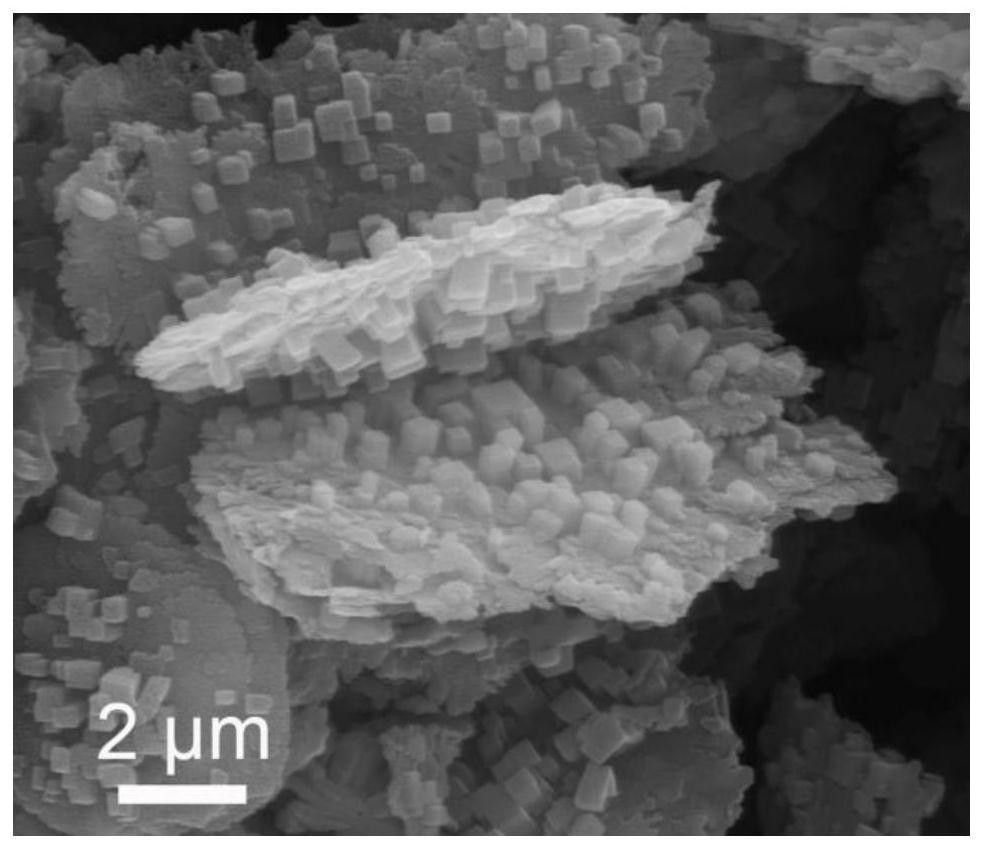

[0043] S1 Measure cumene 15mL and chlorobenzene 10mL respectively and mix them as a good solvent, weigh 20mg of ferrocenylpyrrolidine C 60 Dissolve in a good solvent and filter twice with a 0.22 micron organic filter to form a dark brown transparent solution; inhale the solution with a syringe and slowly inject 50mL of ethanol along the container wall; seal the above mixed solution at room temperature for 24 hours , a dark brown precipitate was obtained at the bottom of the container; the precipitate was collected at a centrifuge speed of 6000r / min and vacuum-dried at 40°C for 10 hours to obtain a three-dimensional hierarchically grown micro-nano structure, that is, a precursor;

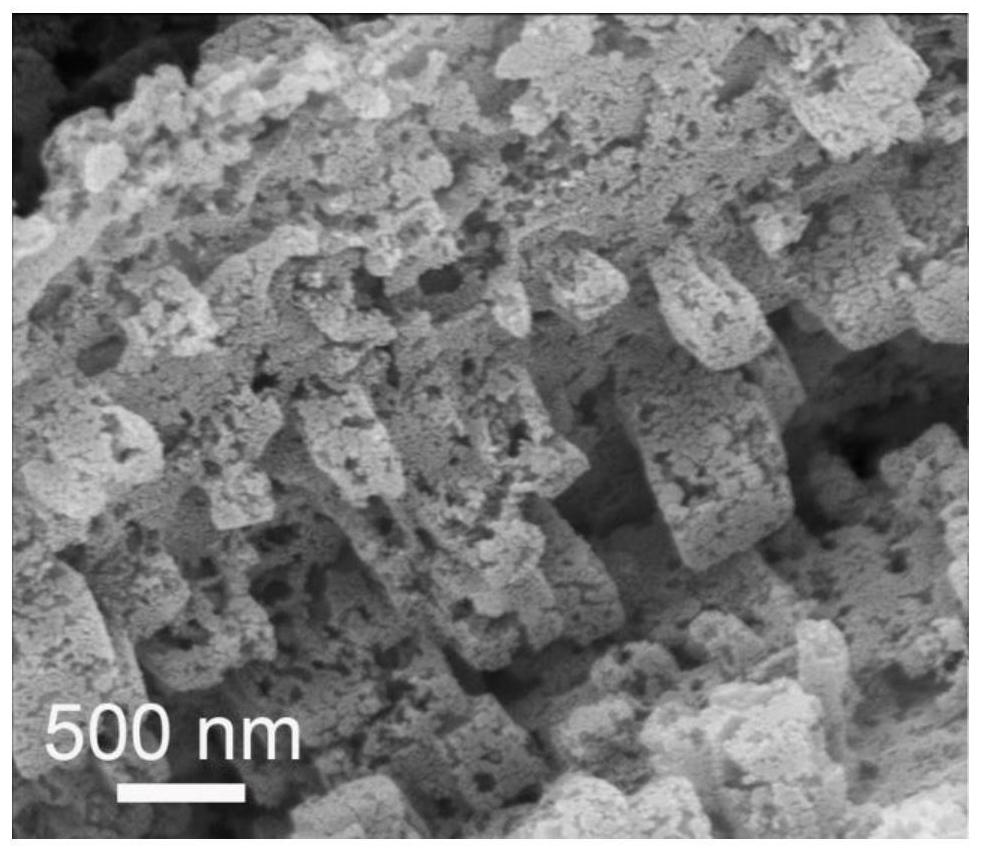

[0044] S2 Place the obtained precursor product in a quartz crucible, raise the temperature to 600°C at a rate of 4°C / min in an ammonia flow rate of 50mL / min and keep it warm for 2 hours to obtain a black powder product, and obtain a fullerene-based Fe , N-doped porous carbon material.

Embodiment 2

[0046] S1 Measure cumene 10mL and chlorobenzene 10mL respectively and mix them as a good solvent, weigh 15mg of ferrocenylpyrrolidine C 60 Dissolve in a good solvent and filter twice with a 0.22 micron organic filter to form a dark brown transparent solution; inhale the solution with a syringe and slowly inject 60mL of ethanol along the container wall; seal the above mixed solution at room temperature for 12 hours , a dark brown precipitate was obtained at the bottom of the container; the precipitate was collected at a centrifuge speed of 6000r / min and vacuum-dried at 40°C for 12 hours to obtain a three-dimensional hierarchically grown micro-nano structure, that is, a precursor;

[0047] S2 Place the obtained precursor product in a corundum crucible, raise the temperature to 700°C at a rate of 5°C / min in an ammonia flow rate of 50mL / min and keep it warm for 3 hours to obtain a black powder product, and obtain a fullerene-based Fe , N-doped porous carbon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com